Preparation method of snake bone device of endoscope

An endoscope and snake bone technology, applied in the field of snake bone devices, can solve the problems of inability to guarantee rivet clearance, failure to achieve track bending, unqualified riveting quality, etc., to shorten detection time, ensure positioning accuracy, reduce The effect of processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described below in conjunction with the accompanying drawings and given embodiments, but is not limited thereto.

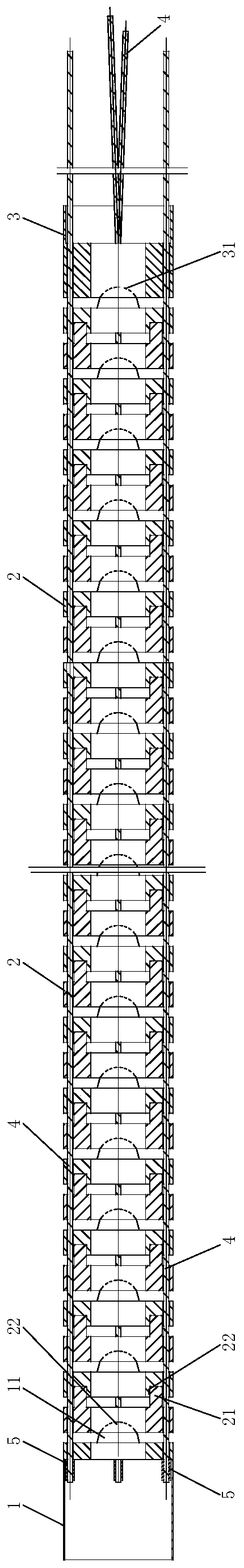

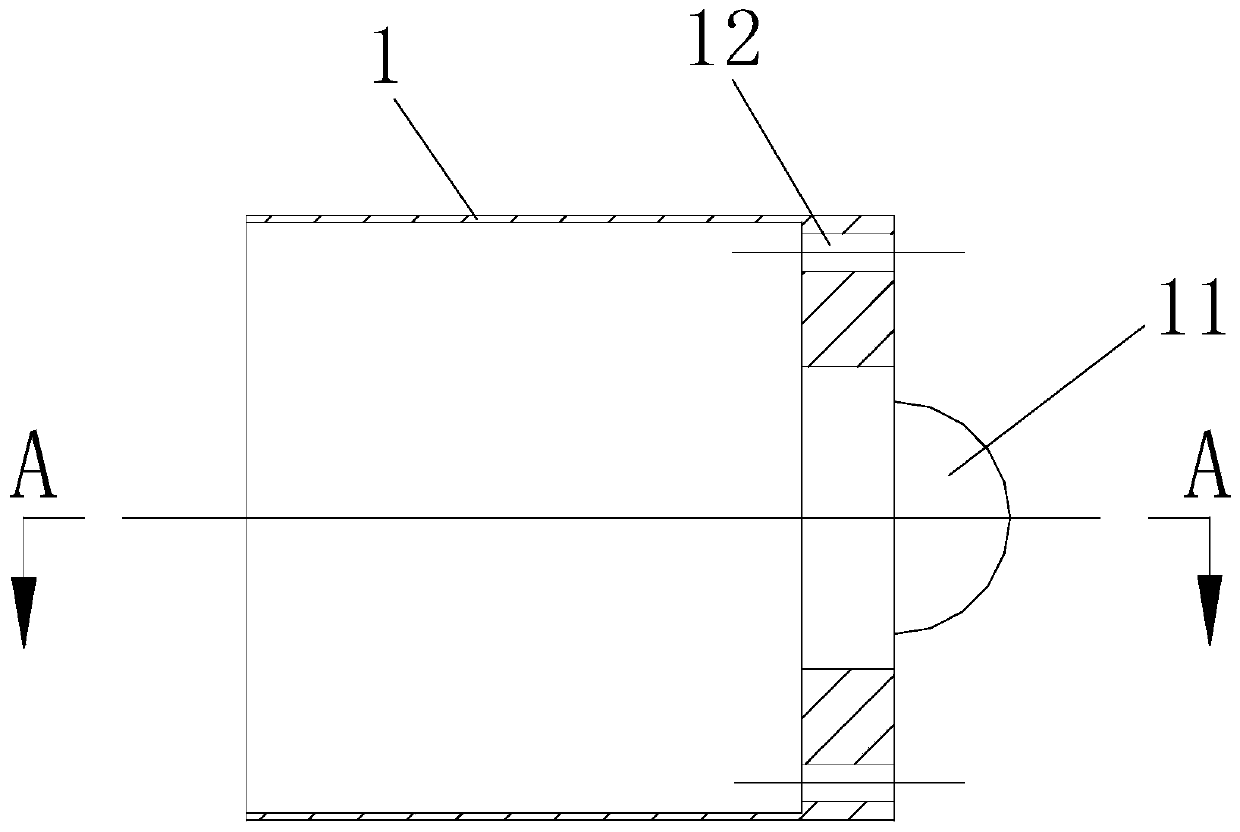

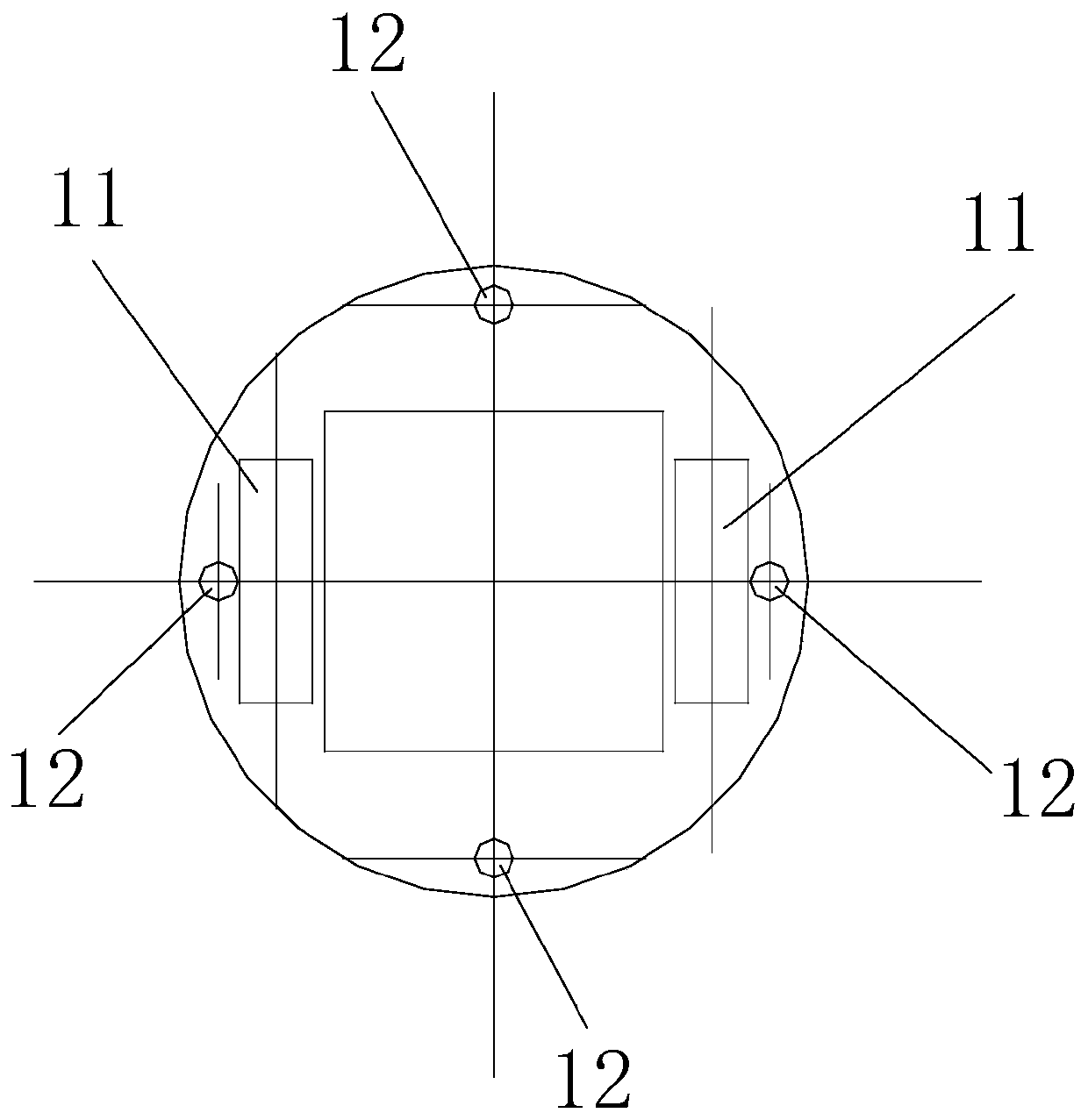

[0061] Such as Figure 1~17 Shown, a kind of preparation method of the snake-bone device of endoscope, described snake-bone device comprises anterior segment ring 1, rear segment ring 2 and several intermediate segments arranged between front segment ring 1 and rear segment ring 3 Circle 2, the specific preparation steps are as follows:

[0062] 1. Material selection and preparation before processing:

[0063] a. The inner and outer diameters of the front segment ring 1, the middle segment ring 2 and the rear segment ring 3 are the same, the outer diameter is 8.5mm, and the inner diameter is 4mm. Stainless steel tubes, stainless steel rods, brass tubes and One of the brass rods, the stainless steel tube is selected in this embodiment,

[0064] b. Preparation before processing:

[0065] Such as Figure 11 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com