Preparing method of antirust paint

A preparation method and technology of anti-rust paint, applied in anti-corrosion coatings, cocoa, grain treatment and other directions, can solve the problems of local high temperature, temperature rise, stability damage, etc., to avoid the reduction of component activity, improve efficiency, improve Formulated Quality Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

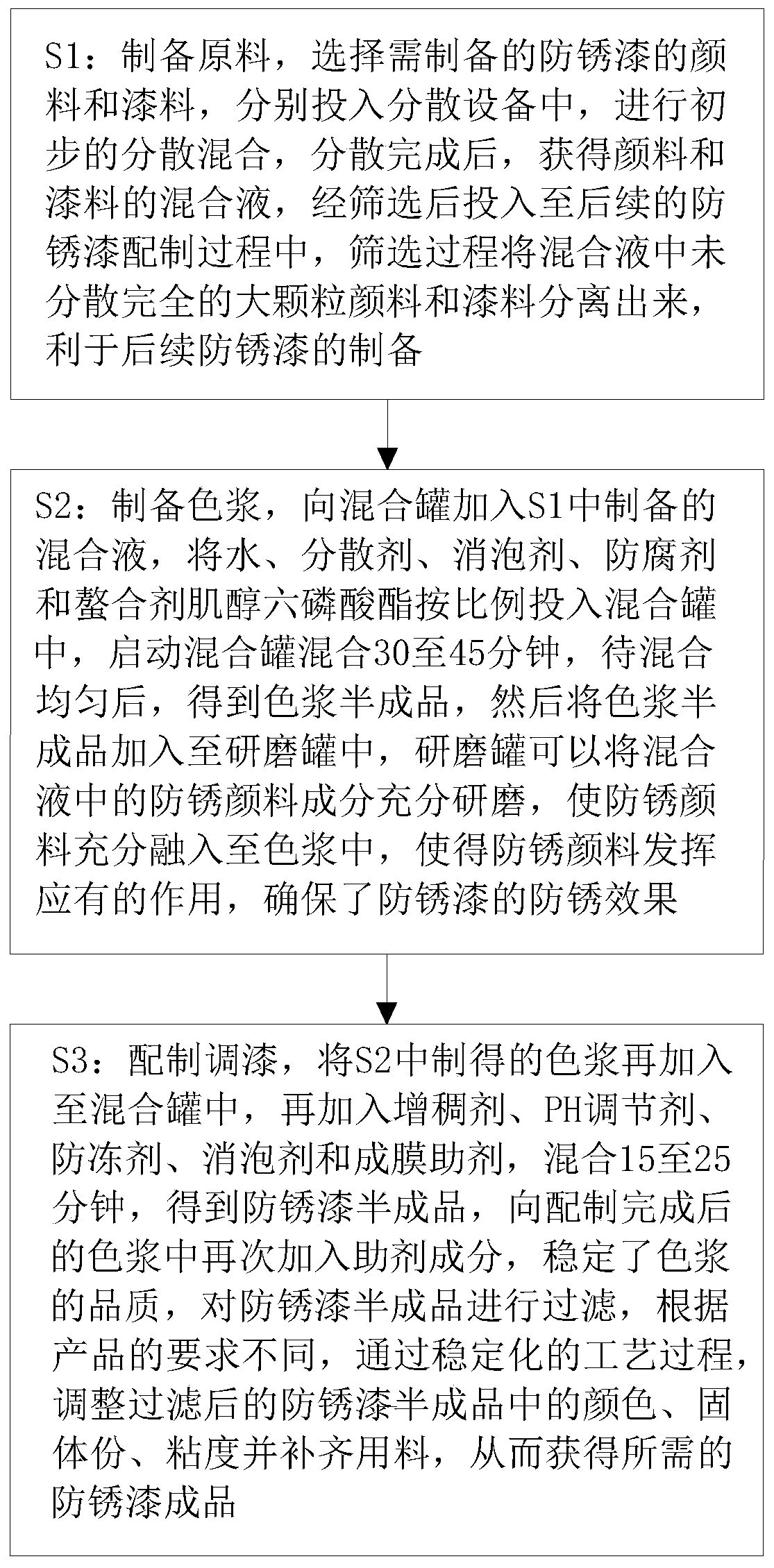

Method used

Image

Examples

Embodiment approach

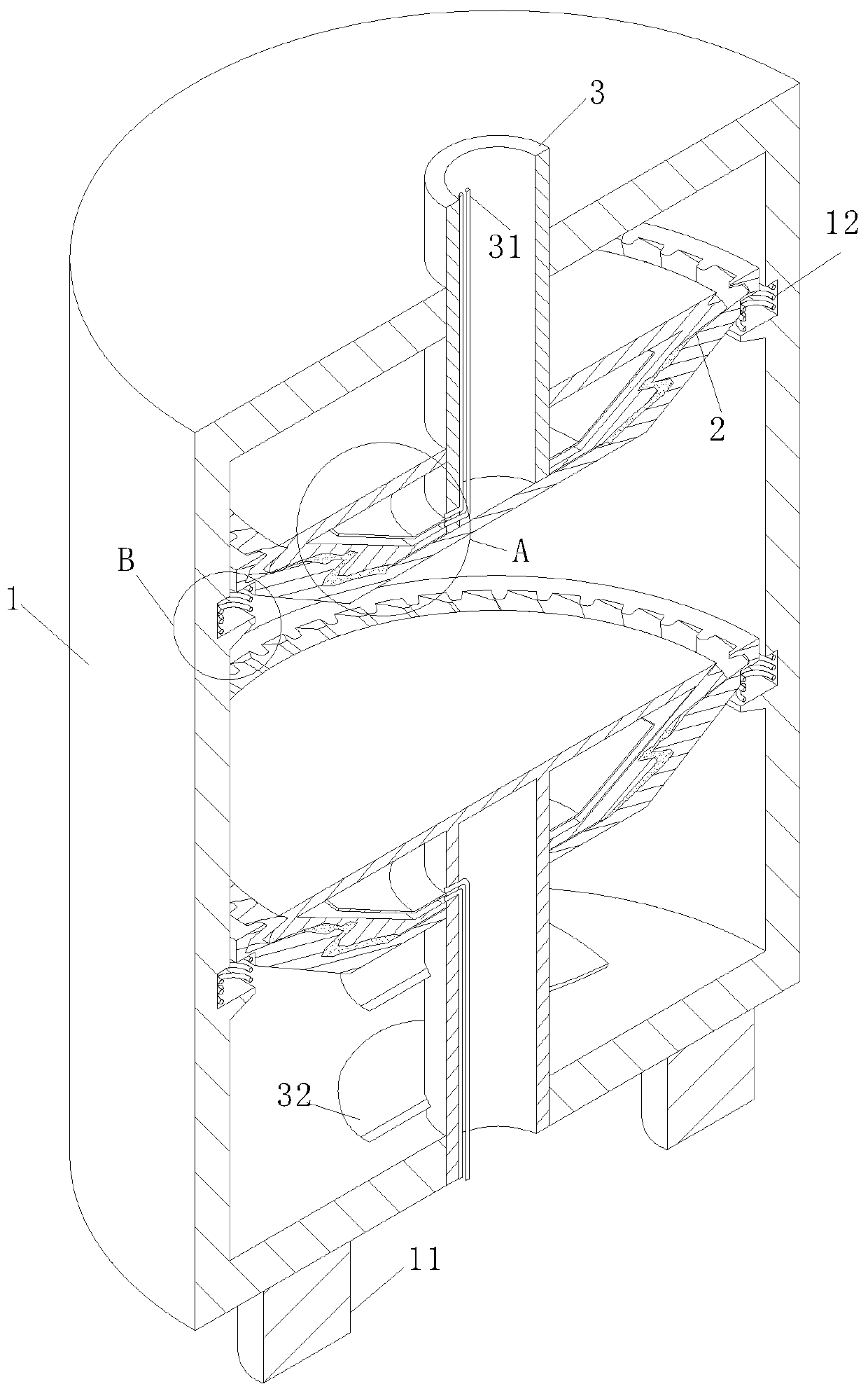

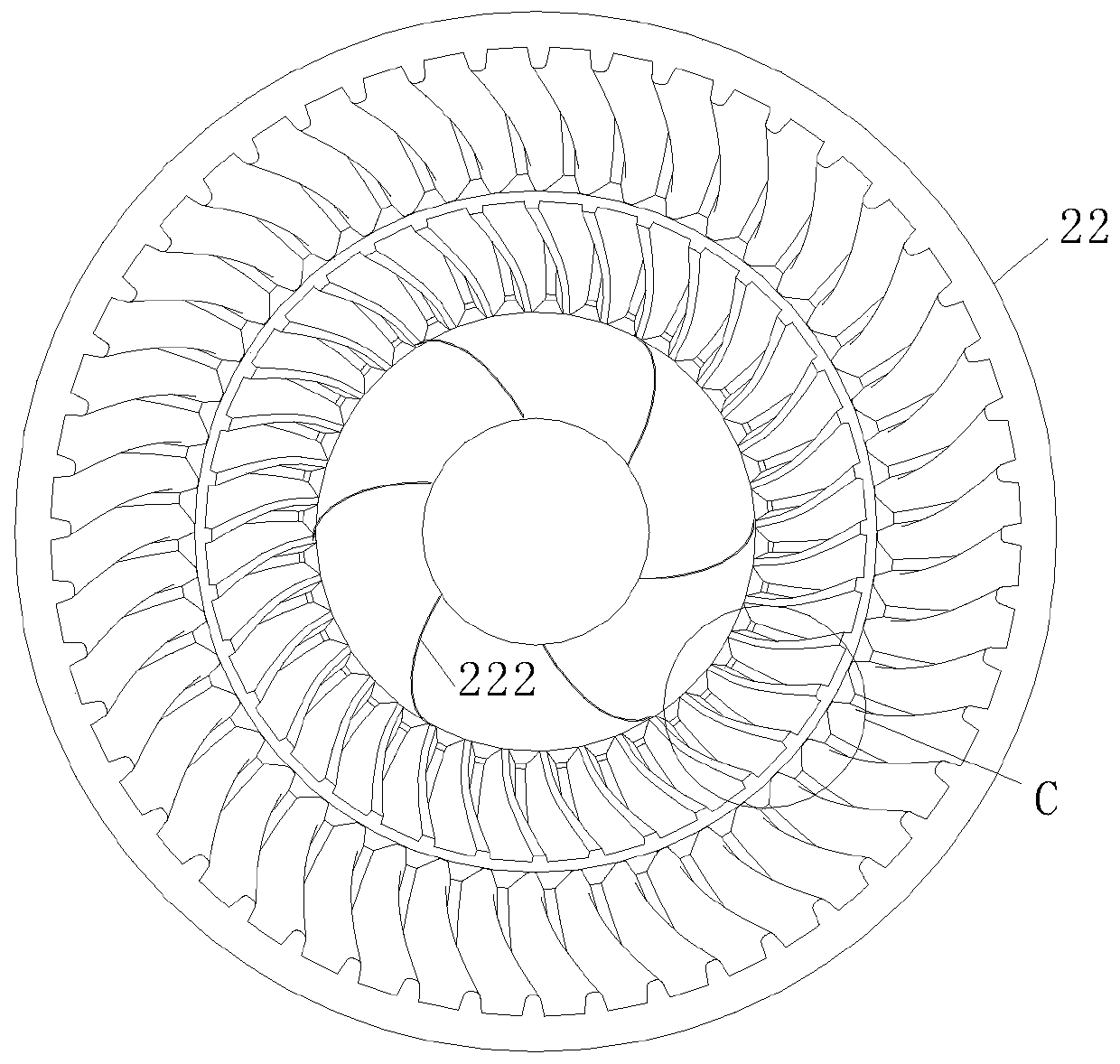

[0035] As an embodiment of the present invention, the grinding disc 2 includes an upper grinding disc 21 and a lower grinding disc 22, the grinding disc 2 is in the shape of an inverted truncated cone, and the grinding disc 2 is filled with abrasive grains 23; the upper grinding disc 21 and the lower grinding disc The contact surface of 22 is the meshing grinding teeth 24; the grinding teeth 24 include coarse teeth and fine teeth arranged up and down; the upper grinding disc 21 is fixedly connected to the rotating shaft 3, and is driven by the rotating shaft 3 to rotate relative to the tank body 1; The lower grinding disc 22 is fixedly installed on the inner wall of the tank body 1, and the bottom of the fine-toothed alveolar grooves of the lower grinding disc 22 is provided with a filter hole 221; when in use, the color paste added to the grinding disc 2 is unevenly distributed, so that the grinding disc 2 When grinding, there are too many anti-rust pigments to be ground in so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com