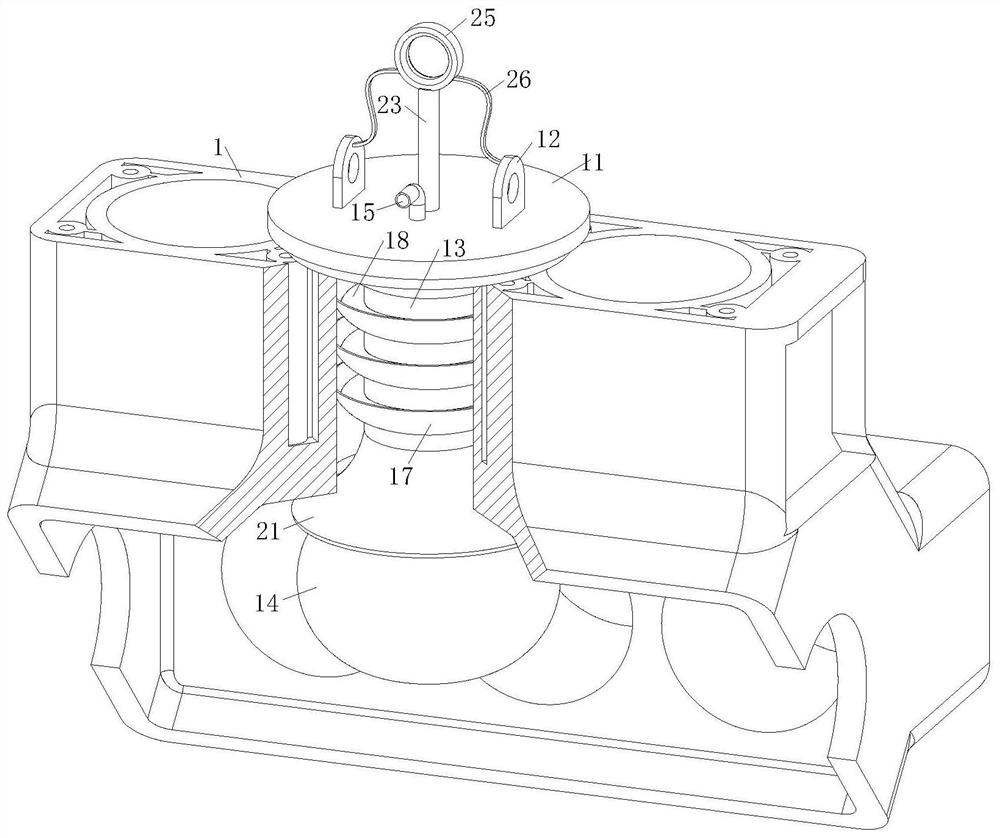

A Hand Claw for Carrying Engine Cylinder with Self-adjusting Function

A technology for engine cylinders and handling hands, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of unguaranteed gripping force, poor rigidity, and high cost, so as to improve fixing and handling efficiency, reduce swaying, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

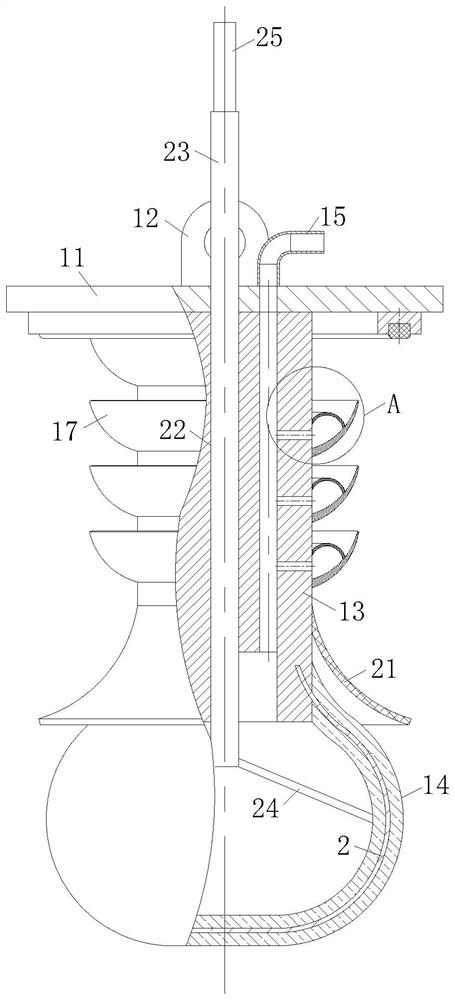

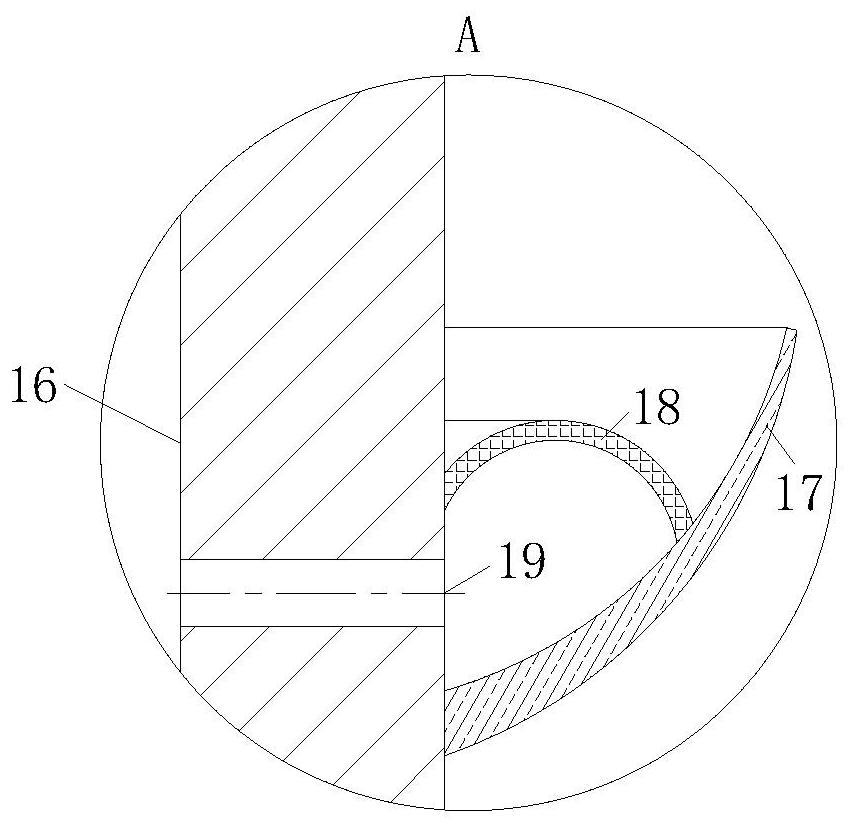

[0021] As an embodiment of the present invention, a group of umbrella-shaped elastic protective sheets 17 are fixedly connected to the outer periphery of the round rod 13, and the thickness of the elastic protective sheets 17 gradually decreases from the root to the outer edge. It is used to reduce the impact of the round rod 13 on the cylinder; through the isolation of the elastic guard 17, the rigid contact between the round rod 13 and the inner wall and edge of the cylinder is isolated, thereby reducing the damage to the cylinder 1 during the handling process, and further increasing the handling grip. handling efficiency.

[0022] As an embodiment of the present invention, the root of the elastic protection sheet 17 is provided with an annular support bag 18, and the support bag 18 communicates with the vent hole 16 through the first hole 19; support force to reduce the shaking of the cylinder body 1; when the expansion ball 14 passes compressed air and then clamps the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com