Impulse pin and method for eliminating stress on weld joint through ultrasonic impact treatment of impulse pin

A welding seam stress and ultrasonic impact technology, applied in the field of ultrasonic impact, can solve problems such as the inability of the vibrating needle, the bumping of the thread, and the inability to continuously remove the stress of the weld, so that the overall strength will not decrease, avoid damage, and increase the welding stress The effect of eliminating the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail below in conjunction with accompanying drawing:

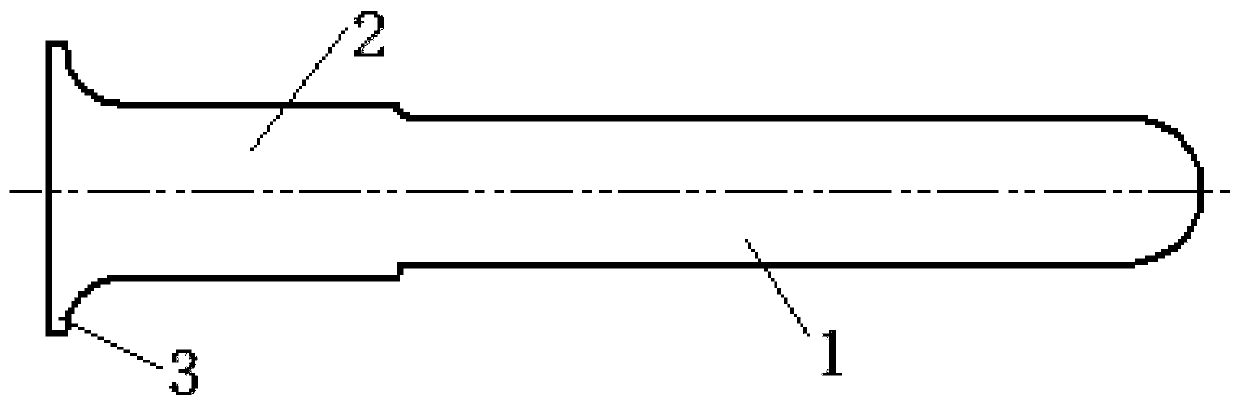

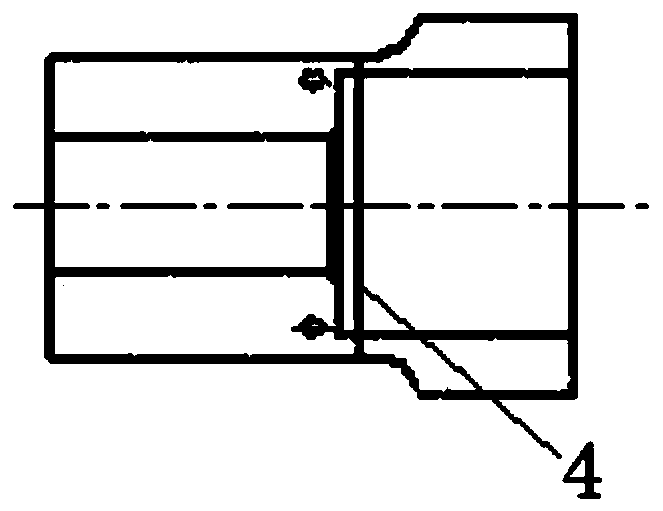

[0027] see figure 1 As shown, it is an impact needle according to the present invention, and the impact needle includes a coaxial needle head 1 , a transition section 2 and a needle tail 3 sequentially connected.

[0028] The front end of the needle head 1 is spherical; the diameter of the transition section 2 is larger than that of the needle head 1, and the transition section 2 is used to ensure the strength of the impact needle when the length of the impact needle is long; the diameter of the needle tail 3 is larger than the diameter of the transition section 2, and the needle tail 3 Used to mount the impact needle on the vibration mount of the impact gun.

[0029] The length of the impact needle is 44mm±0.5mm, the length of the needle 1 is 30mm±0.5mm, the diameter of the transition section 2 is 6mm±0.2mm, and the radius of the spherical part at the front end of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com