Post-grouting construction of pile ends and grouting failure treatment device

A processing device and post-grouting technology, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as inability to perform remedial grouting, potential safety hazards of buildings, and impossibility of post-grouting, etc., to achieve the effect of grouting Good, geological stress dispersion, uniform grouting range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. It should be noted that, unless otherwise clearly specified and limited, the terms "installation", "connection", "connection" and "setting" should be understood in a broad sense, and those of ordinary skill in the art may understand The specific meanings of the above terms in this patent.

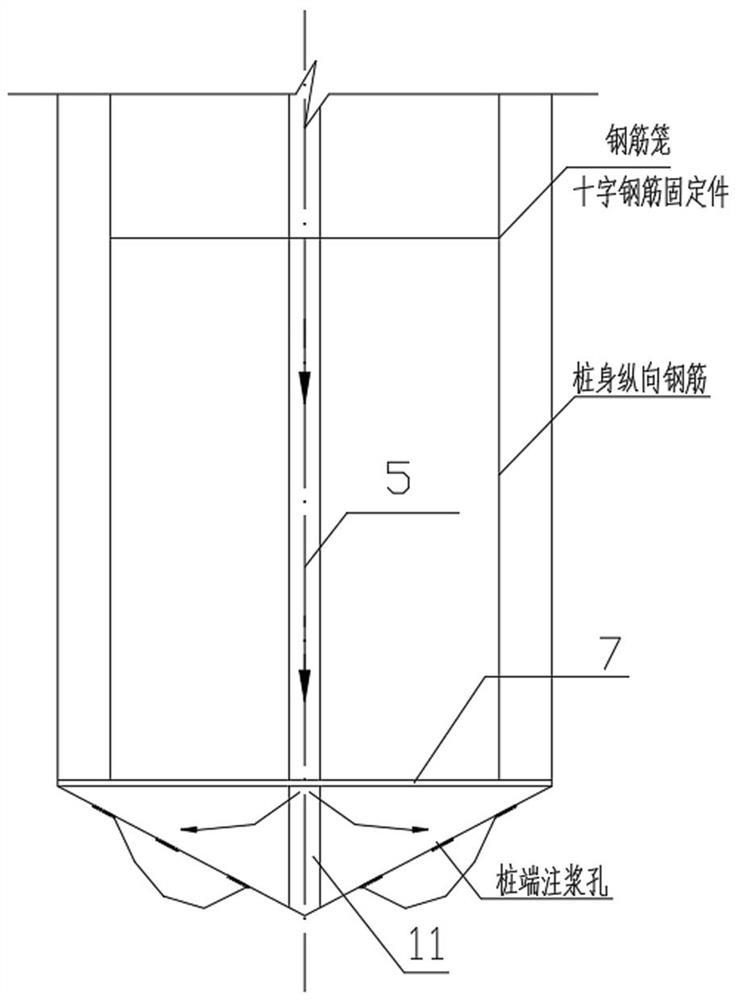

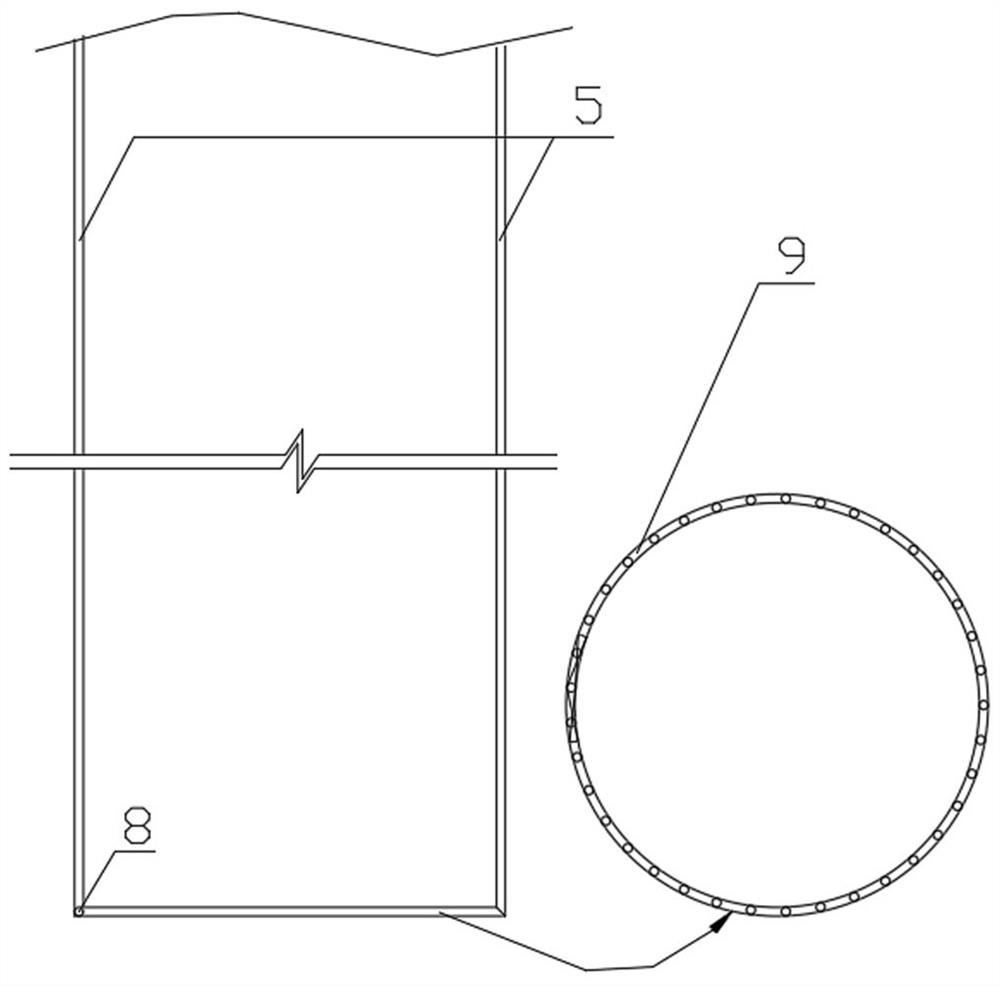

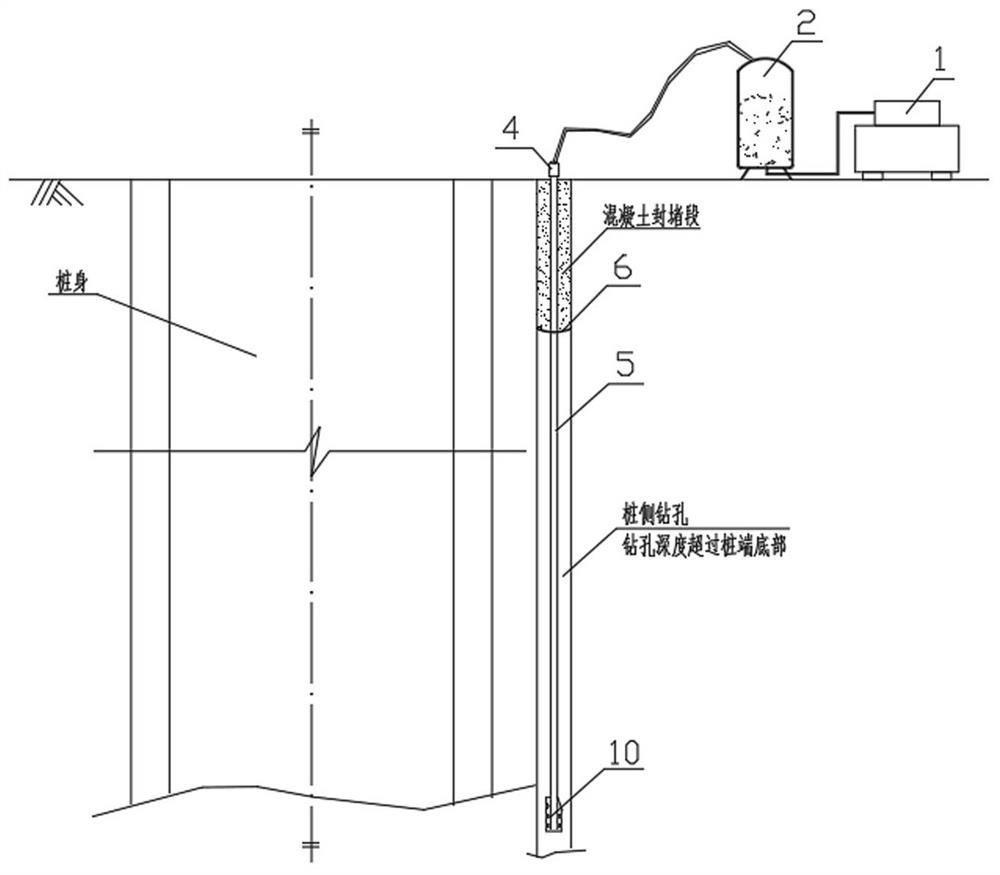

[0034] refer to Figure 1-5 , post-pile grouting construction and grouting failure treatment device, including a slurry mixer truck 1 and a high-pressure grouting bin 2, the slurry mixer truck 1 includes a mixer truck body, and a driving battery and a mixing box are fixedly installed on the outer wall of the top of the mixer truck body, A stirring motor is fixedly installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com