High-flowing-speed air valve used for air cannon launching device

A launching device and high flow rate technology, which is applied in the field of air flow valve, can solve the problems of large error of armor shell damage, inability to judge the force of shells, unstable thrust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

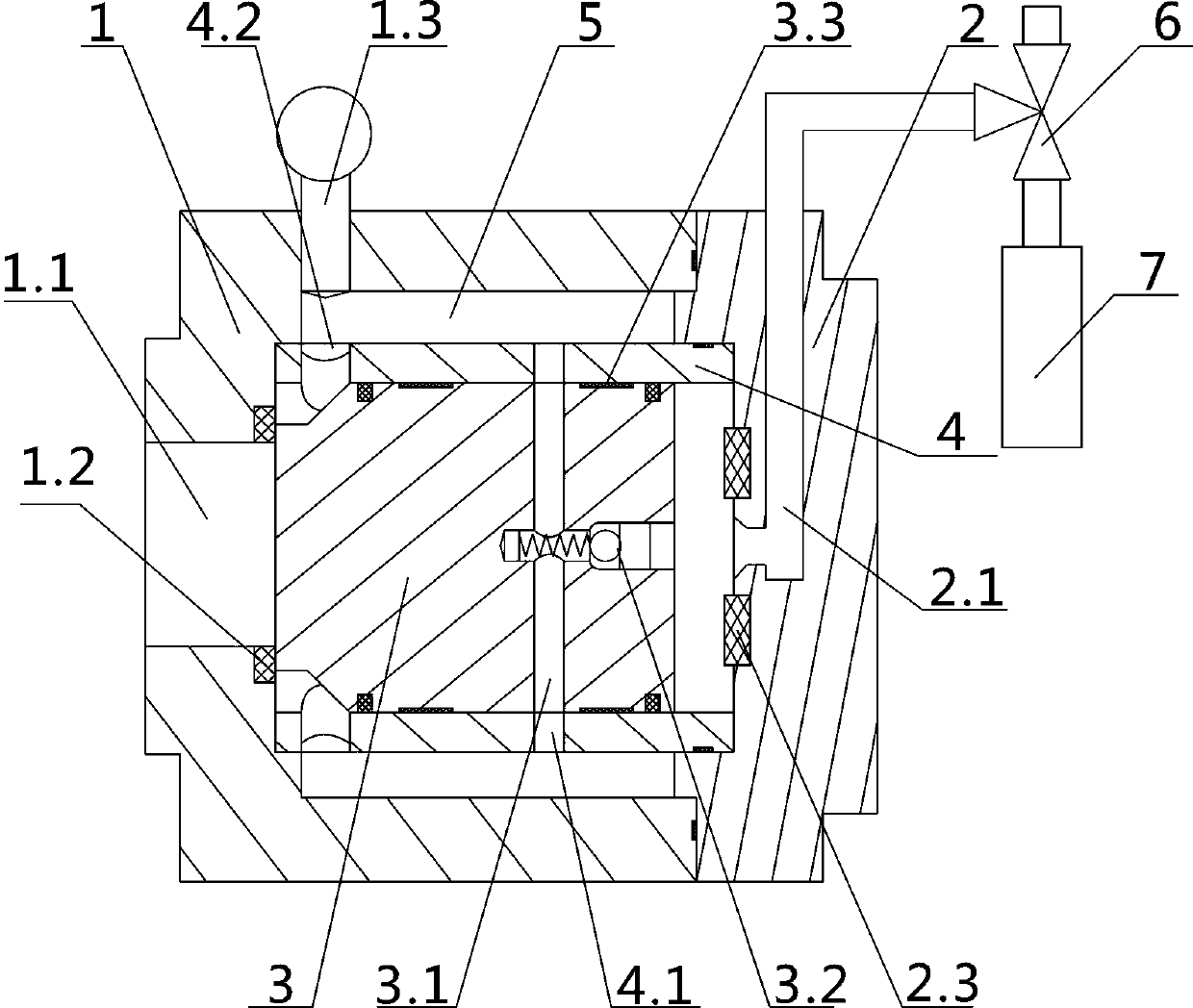

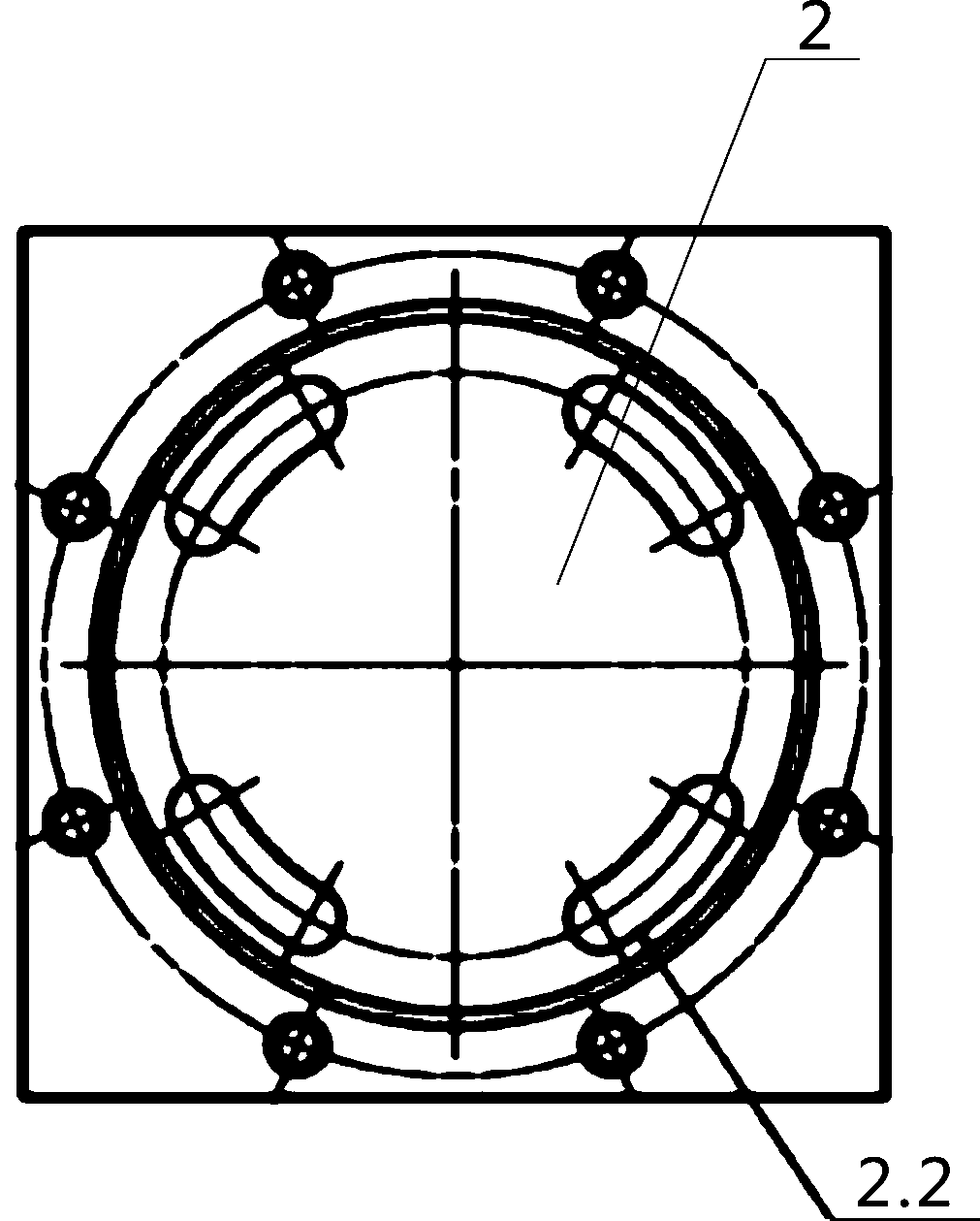

[0024] combined with Figure 1-2 Described a kind of high-flow rate gas valve that is used for air cannon launching device, comprises housing 1, valve core assembly and tail cover 2; The end face is provided with an air release channel 1.1, one end of the air release channel 1.1 communicates with the inner cavity of the shell 1, the other end of the air release channel 1.1 communicates with the external air cannon launcher through a pipeline, and the head end of the tail cover 2 is connected to the shell The tail end of 1 corresponds to a sealed connection. According to requirements, the head end surface of the tail cap 2 is provided with a buffer ring 2.3 corresponding to the tail end of the valve core 3, and the end face of the buffer ring 2.3 protrudes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com