Experimental method for capturing full-period forms of gas hydrate crystals

A technology of gas hydrate and experimental method, which is applied in the visual experiment field of gas hydrate crystal full-cycle capture, which can solve the problems of long induction time under low temperature and high pressure conditions, difficult capture, and failure to capture hydrate crystal growth, etc., to achieve shortened The effect of induction time and simple experimental operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

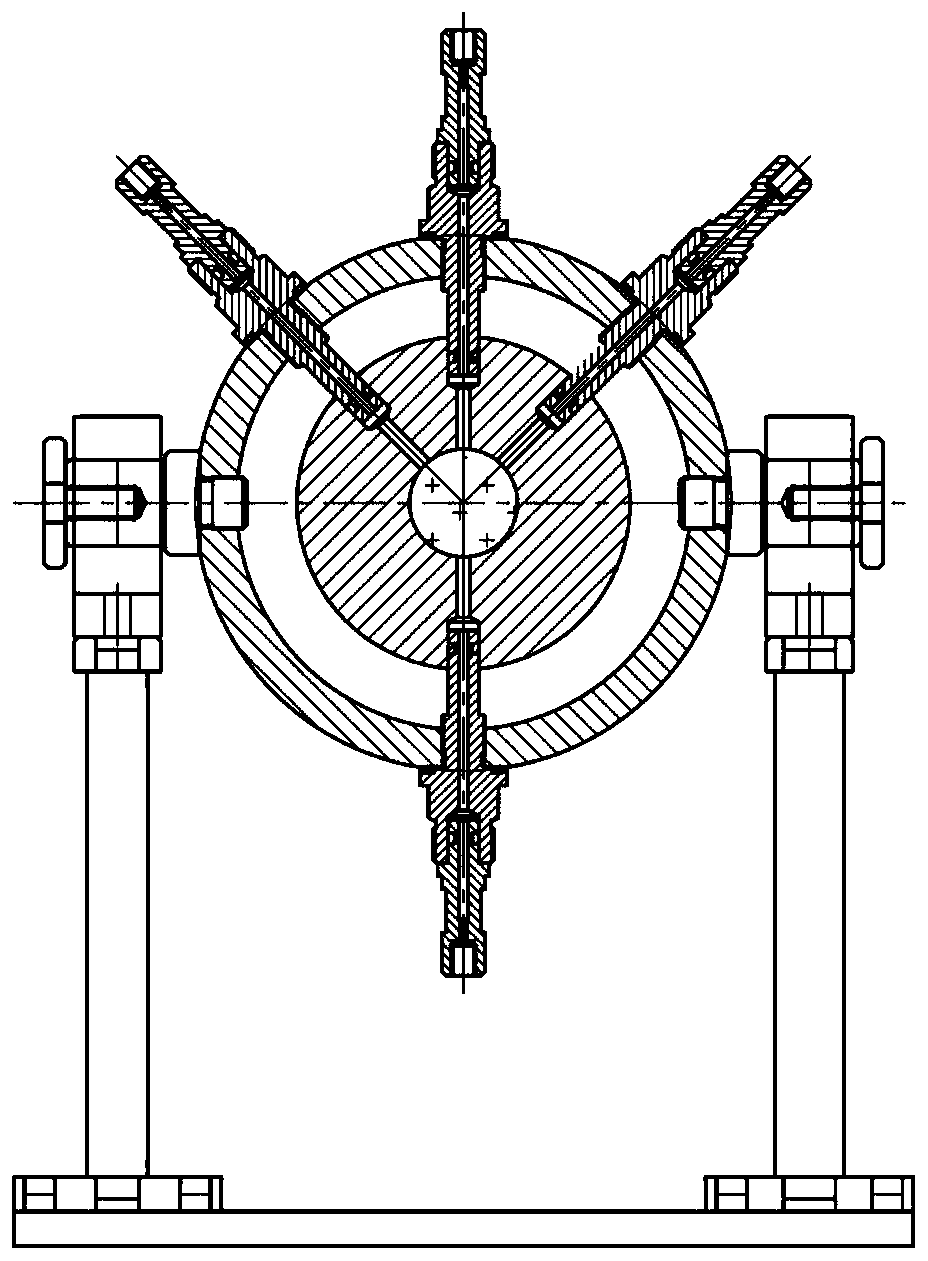

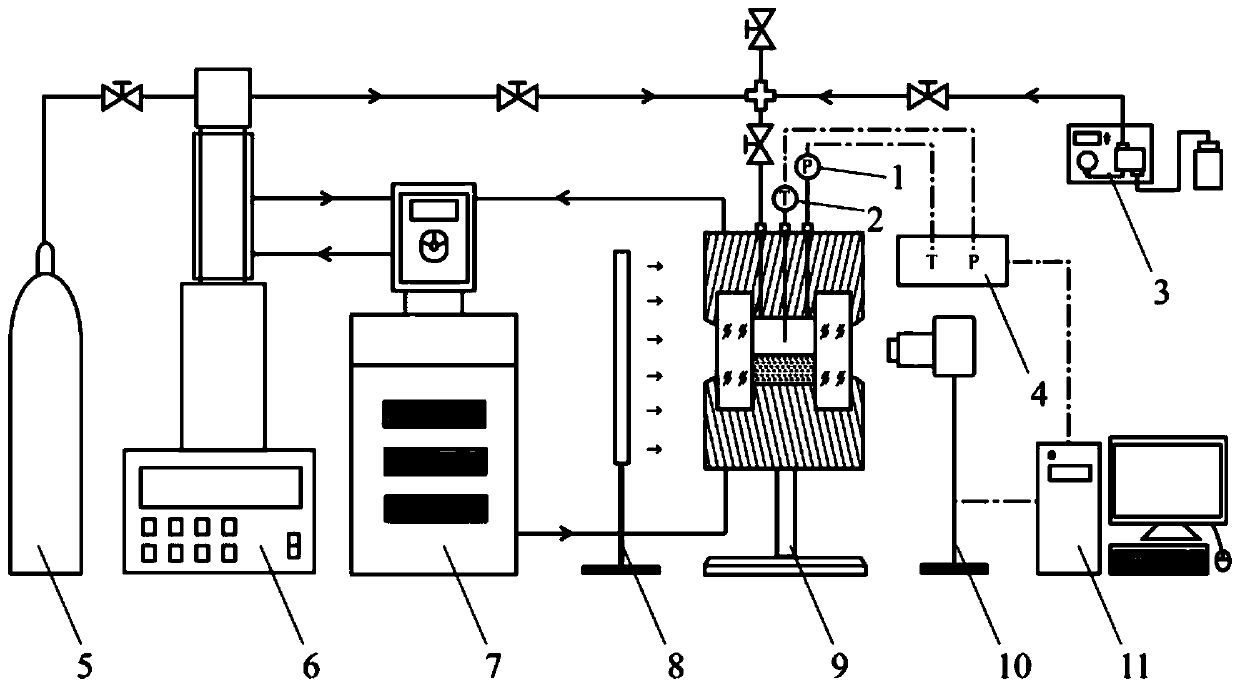

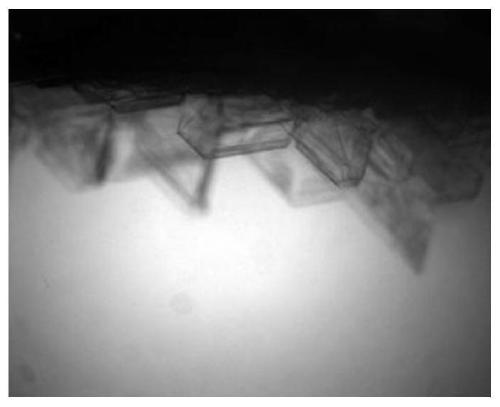

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with specific technical solutions and accompanying drawings.

[0023] An example is at 3MPa, 16°C, carbon dioxide + thermodynamic additive 3mol% tetrahydrofuran solution, to complete the trapping of gas hydrate crystals. Through literature research, it is found that under this concentration of additives, the corresponding phase equilibrium temperature of carbon dioxide at 3MPa is 17°C. The specific implementation includes the following steps:

[0024] (1) Assemble and connect the experimental system, and complete the pipeline leak detection.

[0025] (2) Configure 3.0mol% tetrahydrofuran solution, open the liquid inlet valve, inject 3.5 ml of 3.0mol% tetrahydrofuran solution from the liquid inlet port on the upper end of the reactor body through the liquid injection pump until the liquid level reaches the center of the reactor, and close the liquid inlet valve ;Fill the gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com