Avionics HMI interface-oriented intelligent test system and test method

A test system and test method technology, which is applied in the field of intelligent test systems for avionics HMI interfaces, can solve problems such as missed tests, long-term repeated tests, and difficult to test accurately, so as to improve efficiency, improve data traceability, Effect of reducing test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

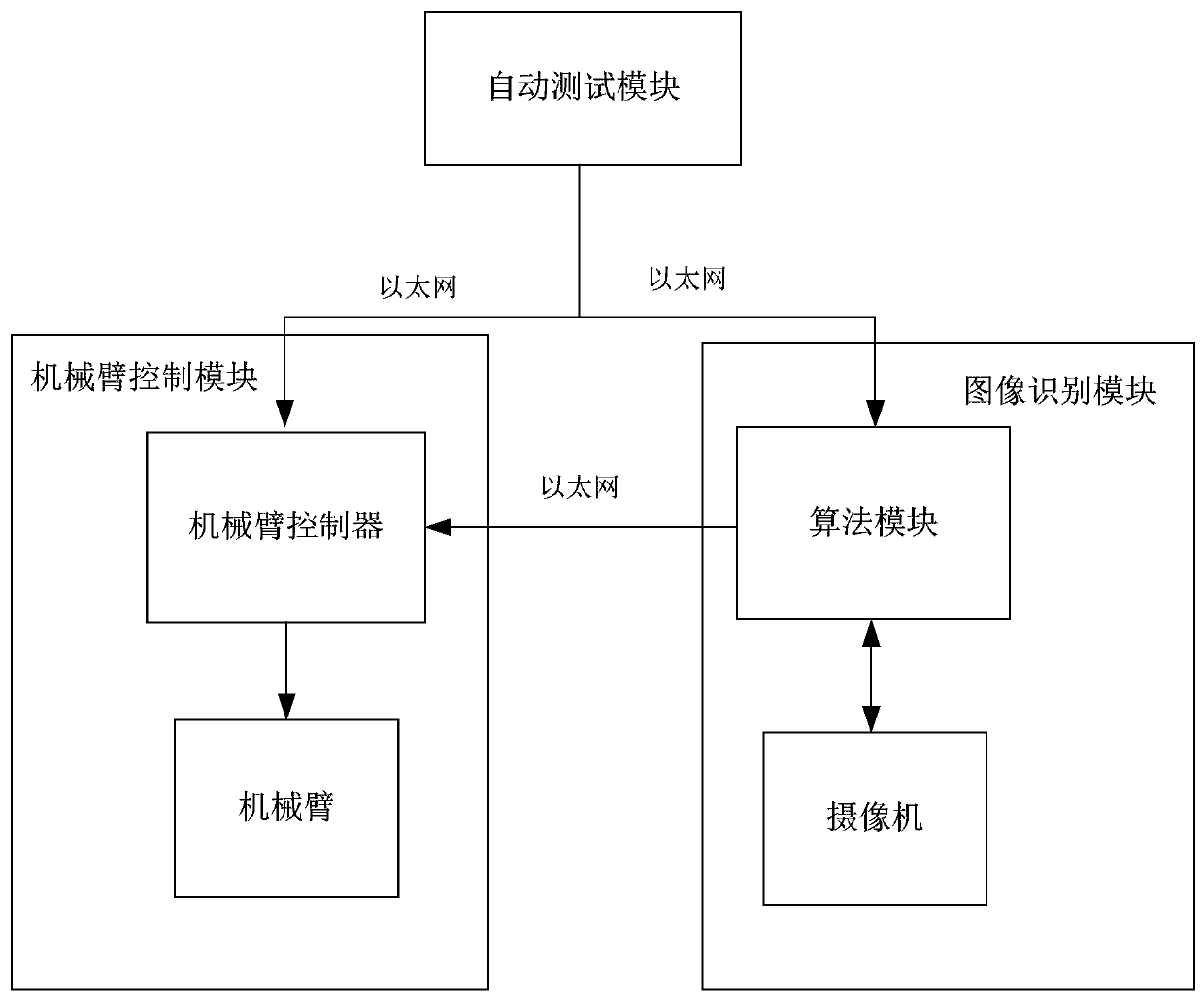

[0029] like figure 1 As shown, an intelligent test system for the HMI interface of avionics includes an automatic test module, an image recognition module and a manipulator module; the image recognition module includes an algorithm module and a camera, and the manipulator module includes a manipulator controller and a manipulator. On the one hand, the automatic test system is connected to the manipulator controller in the manipulator control module through Ethernet, and on the other hand, it is connected to the algorithm module in the image recognition module through Ethernet. The automatic test module assigns test tasks to Manipulator controller and algorithm module. The algorithm module is connected to the camera. After receiving the test task, the algorithm module transmits the target information to be tested to the camera. The camera collects the information of the target to be tested and returns the information to the algorithm module, which processes the image informatio...

Embodiment 2

[0031] Preferably, there is also a database in the system, which is respectively connected to the automatic test module, the image recognition module and the manipulator module, and stores test task information and image data, which is convenient for later analysis and calling.

Embodiment 3

[0033] Preferably, multiple robotic arms can be connected to the system for parallel testing. For example, if there are two robotic arms in the system, the content of the test task will be divided into two parts. Suppose the test task is divided into "button" and "touch". After receiving the "key" command, the first robotic arm performs key operations on the target through the robotic arm controller, and after receiving the "touch screen" command, the second robotic arm performs key operations on the target through the robotic arm controller. Perform touch screen operations. In this way, the system can test the test target at the same time, which improves the work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com