A receiving transducer with adjustable working frequency

A technology of working frequency and transducers, applied in piezoelectric/electrostrictive transducers, instruments, sensors, etc., can solve the problems of low sensitivity receiving response, narrow frequency band application range, low sensitivity, etc., and achieve flat receiving response , The overall structure and manufacturing process are simple, and the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

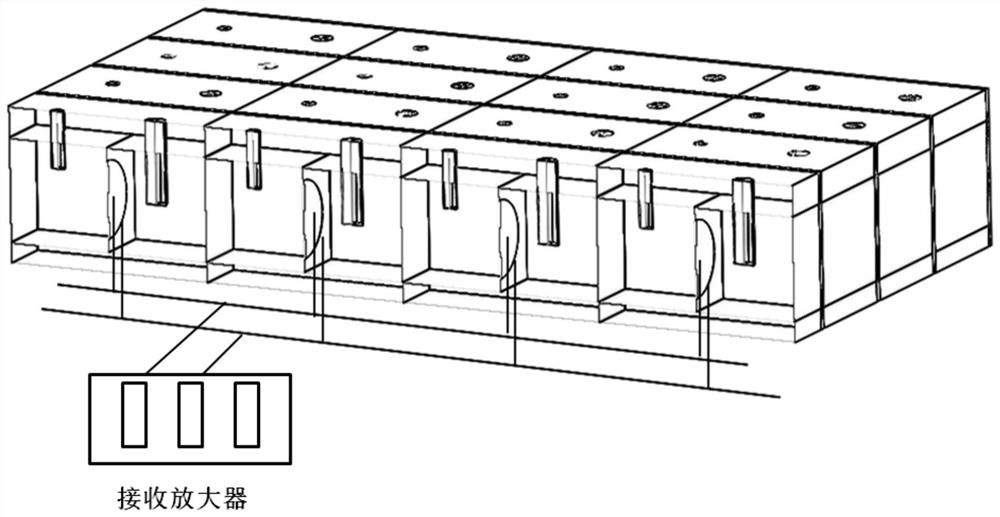

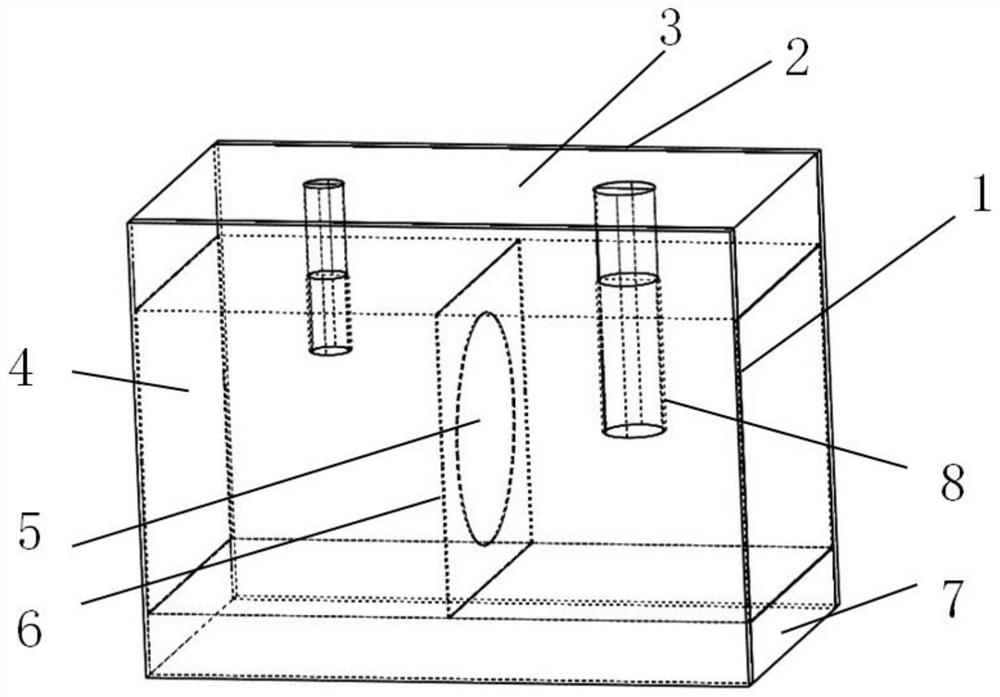

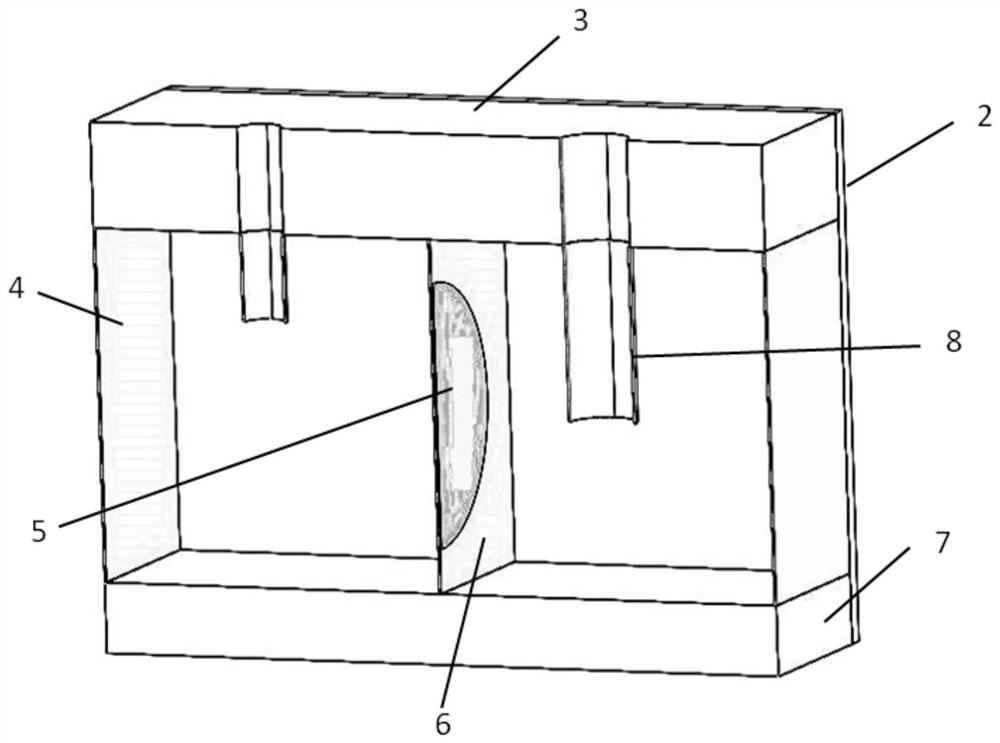

Embodiment 1

[0031] Embodiment 1, adjust the lengths of the thin-walled circular tube extension necks 8 of the two Helmholtz resonant cavities to be L respectively 1 =0mm,L 2 = 9 mm. Use finite element software to model and calculate the voltage value received by the terminal when a plane wave with a sound pressure amplitude of 1 Pa is incident vertically on the top wall 3 of the opening. Through calculation, the extension neck 8 of the thin-walled circular tube is L 1 =0mm,L 2 = The receiving sensitivity frequency response curve at 9mm, please refer to the attached Figure 4 , it can be clearly seen from the figure that the high-sensitivity reception above -30 decibels is achieved near 424Hz.

Embodiment 2

[0032] Embodiment 2, adjust the lengths of the thin-walled circular tube extension necks 8 of the two Helmholtz resonant cavities to be L respectively 1 =15mm, L 2 = 0 mm. Use finite element software to model and calculate the voltage value received by the terminal when a plane wave with a sound pressure amplitude of 1 Pa is incident vertically on the top wall 3 of the hole, and calculate the extension neck 8 of the thin-walled circular tube as L 1 =15mm,L 2 For the frequency response curve of receiving sensitivity at =0mm, please refer to the attached Figure 5 , it can be clearly seen from the figure that a flat sensitivity receiving response is achieved in a wide frequency band.

Embodiment 3

[0033] Embodiment 3, adjust the lengths of the thin-walled circular tube extension necks 8 of the two Helmholtz resonant cavities to be L respectively 1 =5mm,L 2 = 10 mm. Use finite element software to model and calculate the voltage value received by the terminal when a plane wave with a sound pressure amplitude of 1 Pa is incident vertically on the top wall 3 of the opening. Through calculation, the extension neck 8 of the thin-walled circular tube is L 1 =5mm,L 2 = 10mm receiving sensitivity frequency response curve, please refer to the attached Figure 6 , it can be clearly seen from the figure that the sensitivity reception above -40 decibels has been achieved at 300Hz-450Hz.

[0034] The invention realizes a receiving transducer with adjustable working frequency which has a high-sensitivity receiving response to a single-frequency acoustic signal and a flat receiving response to a wide-band acoustic signal. The opposite sound pressure phase will be generated in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com