Thermal treatment method of stainless steel 3D printing material

A heat treatment method and 3D printing technology, applied in additive processing and other directions, can solve problems such as incomplete application, and achieve the effects of short aging time, high hardness and small dimensional changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

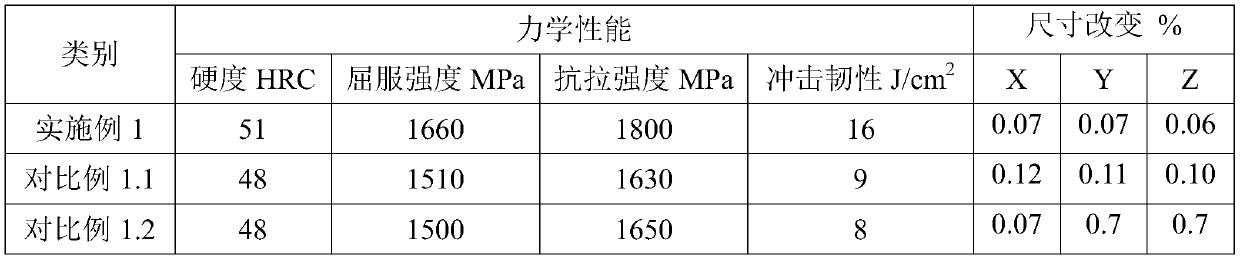

Embodiment 1

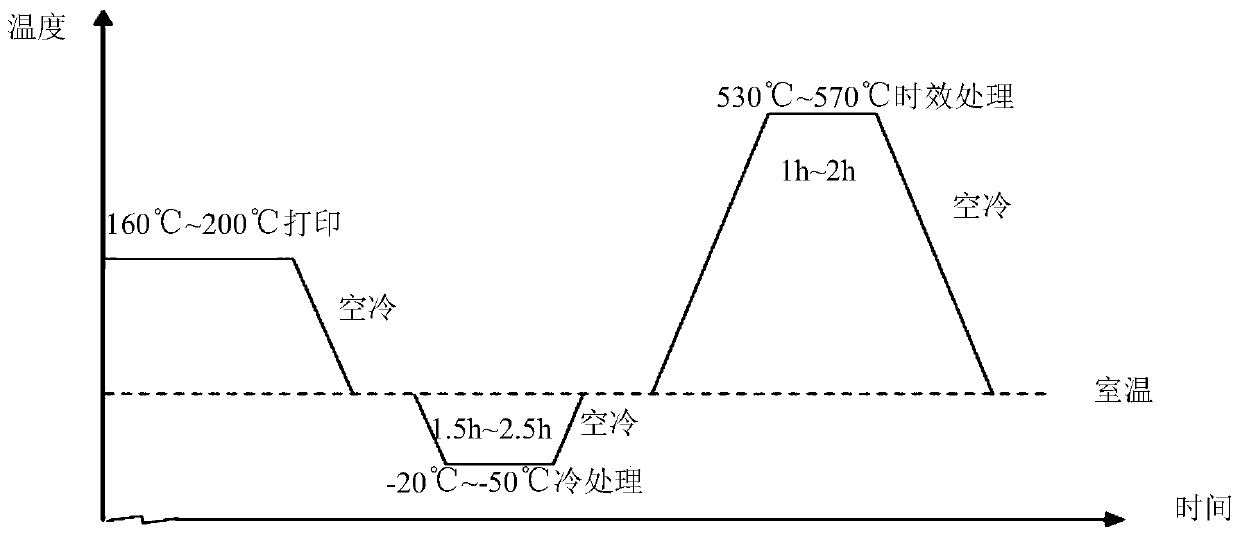

[0025] A 3D printing material heat treatment process disclosed in this embodiment, taking Corrax stainless steel material as an example, includes the following steps:

[0026] Step 1: Part Printing

[0027] Through the 3D printing equipment, the strip scanning strategy is used to print parts of 100×100×30mm, and the heating temperature of the substrate is 200°C;

[0028] Step 2: Cryogenic Treatment

[0029] After the molding is completed, the parts are placed in a cryogenic box for cold treatment at -20°C for 2 hours, and air cooled to room temperature;

[0030] Step 3: Aging Treatment

[0031] After the cold treatment is completed, the parts are placed in a muffle furnace for aging heat treatment. The aging temperature is 550°C, the aging time is 2h, air-cooled to room temperature, and the heat treatment is protected by an Ar atmosphere.

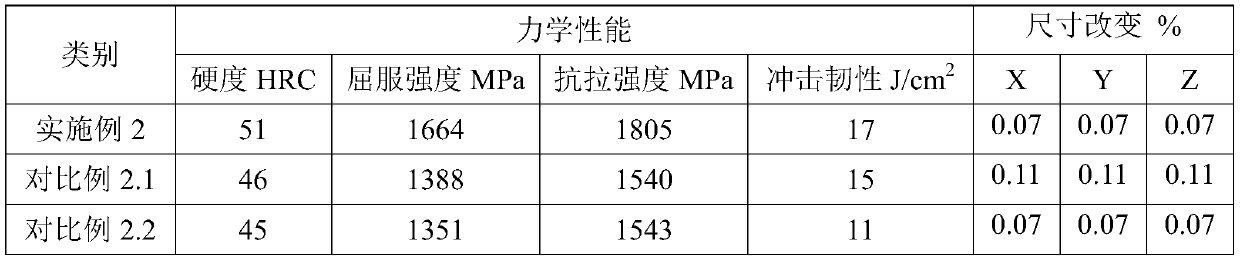

Embodiment 2

[0050] A 3D printing material heat treatment process disclosed in this embodiment, taking Corrax stainless steel material as an example, includes the following steps:

[0051] Step 1: Part Printing

[0052] Through the 3D printing equipment, the strip scanning strategy is used to print parts of 100×100×30mm, and the heating temperature of the substrate is 180°C;

[0053] Step 2: Cryogenic Treatment

[0054] After the molding is completed, the parts are placed in a cryogenic box for cold treatment, the temperature of the cold treatment is -30°C, the time is 1.5h, and air-cooled to room temperature;

[0055] Step 3: Aging Treatment

[0056] After the cold treatment is completed, the parts are placed in a muffle furnace for aging heat treatment. The aging temperature is 560°C, the aging time is 2h, air-cooled to room temperature, and the heat treatment is protected by an Ar atmosphere.

Embodiment 3

[0075] A 3D printing material heat treatment process disclosed in this embodiment, taking Corrax stainless steel material as an example, includes the following steps:

[0076] Step 1: Part Printing

[0077] Through the 3D printing equipment, the strip scanning strategy is used to print parts of 100×100×30mm, and the heating temperature of the substrate is 170°C;

[0078] Step 2: Cryogenic Treatment

[0079] After the molding is completed, the parts are placed in a cryogenic box for cold treatment at -40°C for 2 hours, and air cooled to room temperature;

[0080] Step 3: Aging Treatment

[0081] After the cold treatment is completed, the parts are placed in a muffle furnace for aging heat treatment. The aging temperature is 570°C, the aging time is 2h, air-cooled to room temperature, and the heat treatment is protected by an Ar atmosphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com