Desert sand texture paint and preparation method thereof

A technology of desert sand and texture paint, applied in the direction of coating, etc., can solve the problems of fine desert sand particles, heavy alkalinity, and high mud content, and achieve the effects of reducing pollution and damage, reducing utilization, and compensating for color and color difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

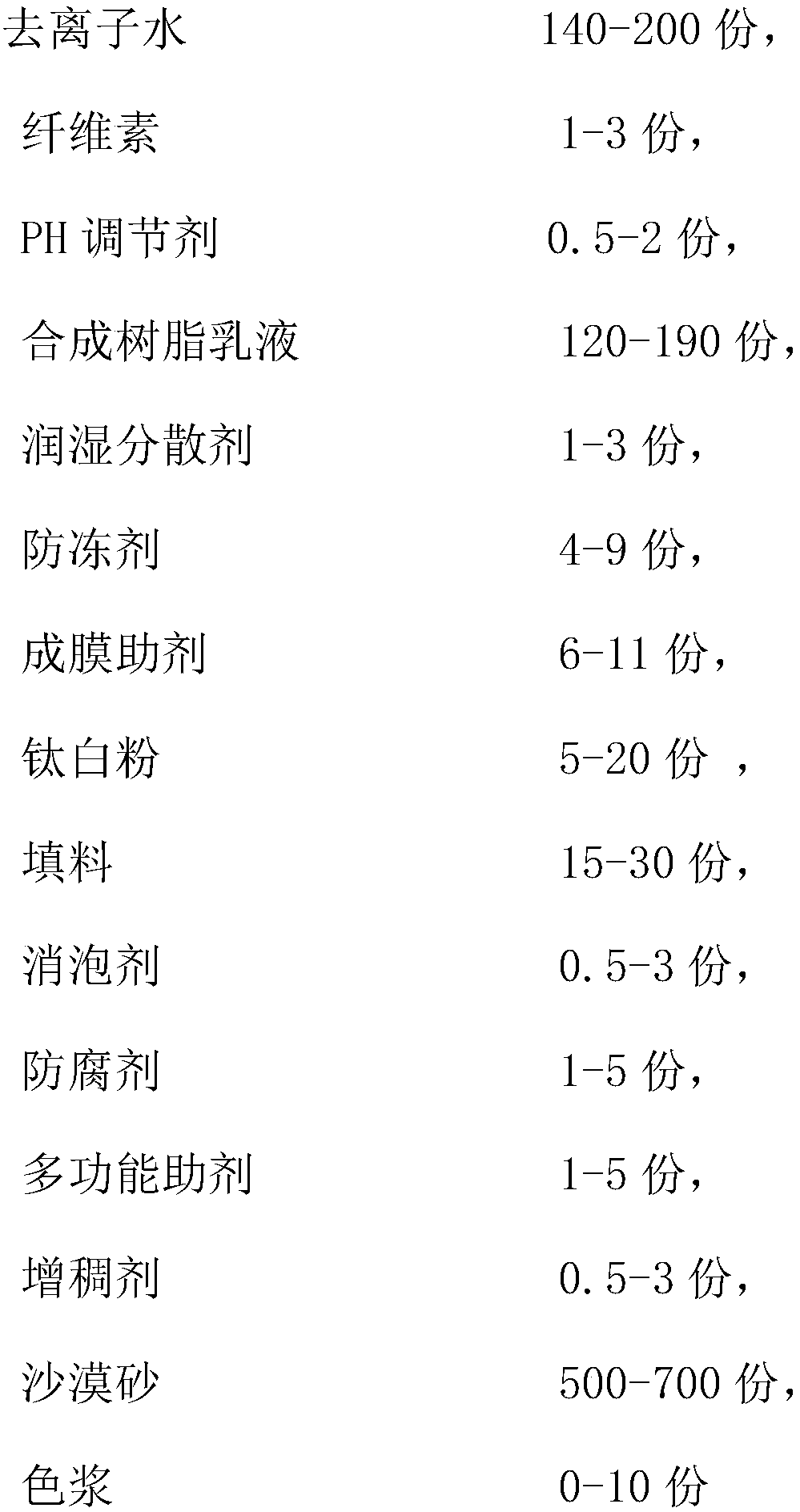

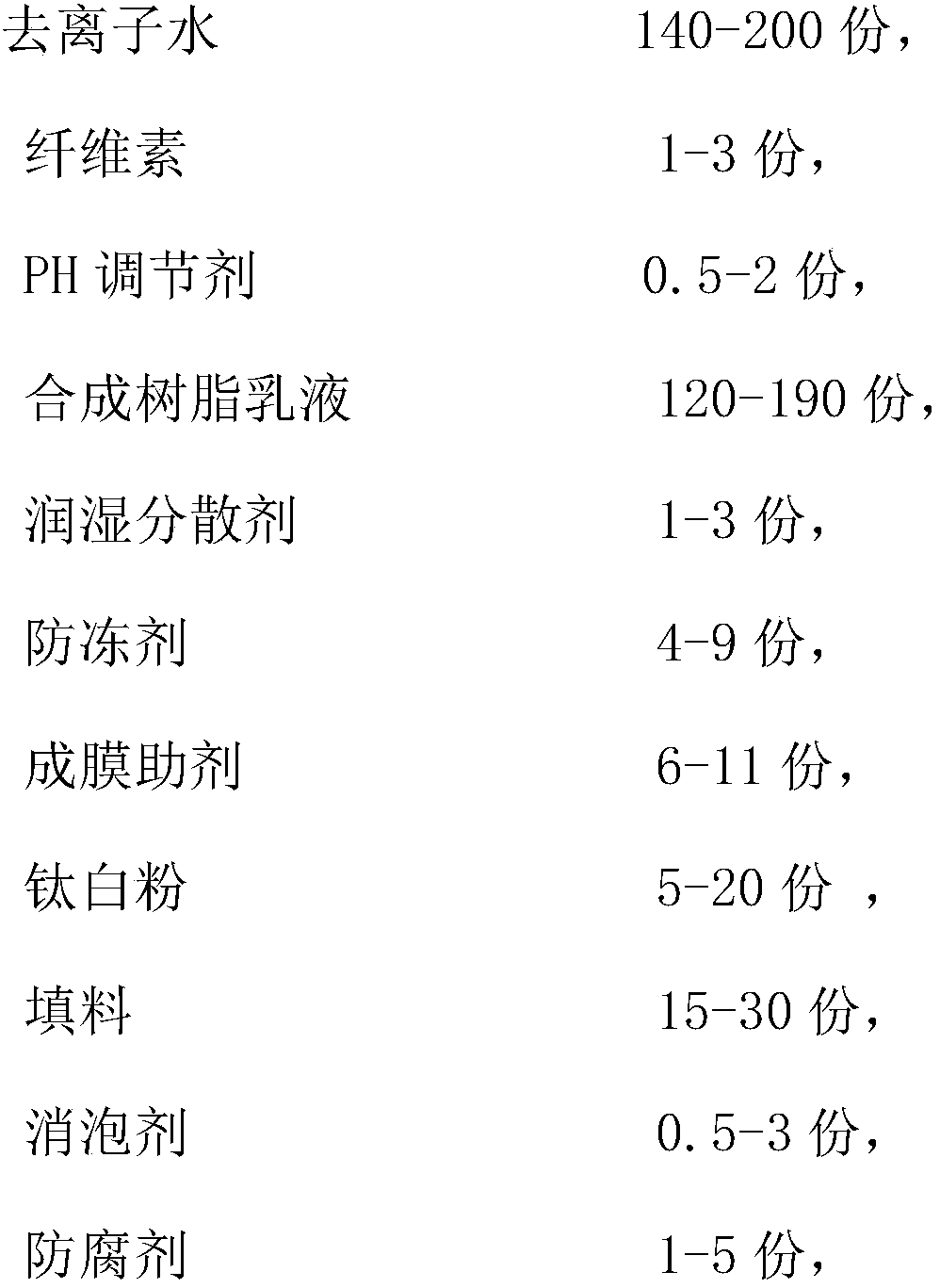

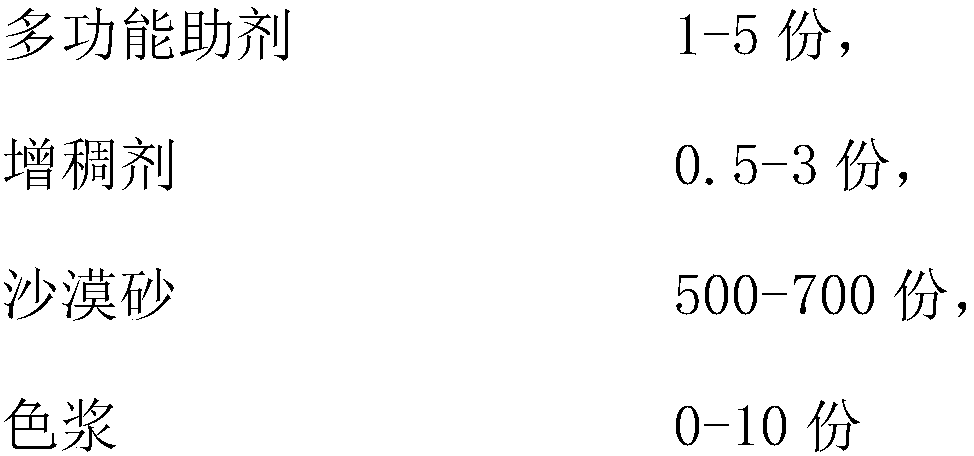

[0048] The desert sand texture paint described in this embodiment is prepared by the following components in parts by weight: 140 parts of deionized water, 1 part of cellulose, 0.5 part of pH regulator, 120 parts of synthetic resin emulsion, 1 part of wetting and dispersing agent, antifreeze 4 parts of agent, 10 parts of film-forming aid, 5 parts of titanium dioxide, 20 parts of filler, 0.5 part of defoamer, 3 parts of preservative, 3 parts of multifunctional additive, 0.5 part of thickener, 500 parts of desert sand (20 -40 mesh), 1.5 parts of iron red paste, 2.5 parts of iron yellow paste, 0.2 part of carbon black paste.

[0049] The preparation method of desert sand texture paint described in the present embodiment comprises the following steps:

[0050] (1) Accurately weigh each component according to the above ratio requirements, pre-mix and stir the antifreeze agent ethylene glycol, film-forming aid alcohol fat twelve, and cellulose at a speed of 400r / min, and then add de...

Embodiment 2

[0057] The desert sand texture paint described in this embodiment is prepared from the following components by weight fraction: 180 parts of deionized water, 2 parts of cellulose, 1 part of pH regulator, 160 parts of synthetic resin emulsion, 2 parts of wetting and dispersing agent, 6 parts of antifreeze, 6 parts of film-forming aids, 15 parts of titanium dioxide, 30 parts of fillers, 2 parts of defoamers, 5 parts of preservatives, 1 part of multifunctional additives, 2 parts of thickeners, 650 parts of desert sand ( 30-40 mesh), 0.02 parts of bright red paste, 0.01 part of chrome yellow paste, 0.03 part of phthalocyanine blue paste, 0.01 part of carbon black paste.

[0058] A kind of preparation method of desert sand texture paint described in the present embodiment, comprises the following steps:

[0059] (1) Accurately weigh each component according to the proportioning requirements of the above-mentioned components, after premixing and stirring the antifreeze agent ethylen...

Embodiment 3

[0066] The desert sand texture paint described in this example is prepared from the following components in parts by weight: 200 parts of deionized water, 3 parts of cellulose, 2 parts of pH regulator, 190 parts of synthetic resin emulsion, and 3 parts of wetting and dispersing agent , 9 parts of antifreeze, 11 parts of film-forming aid, 20 parts of titanium dioxide, 15 parts of filler, 3 parts of defoamer, 1 part of preservative, 5 parts of multifunctional additive, 3 parts of thickener, 350 parts of desert sand (40-80 mesh), 350 parts of desert sand (80-120 mesh), 5 parts of orange red pulp, 3 parts of magenta pulp, 2 parts of permanent purple pulp.

[0067] A kind of desert sand texture paint of the present invention and preparation method thereof, comprises the following steps:

[0068] (1) Accurately weigh each component according to the proportioning requirements of the above components, pre-mix and stir the antifreeze agent ethylene glycol, film-forming aid alcohol fat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap