High-strength high-elongation forged titanium alloy material, preparation method and application thereof

A high elongation, titanium alloy technology, used in golf balls, golf clubs, sports accessories, etc., can solve the problems of reducing golf head manufacturing costs, high costs, disadvantages, etc., to reduce material costs, reduce processing costs, The effect of reducing the number of fires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the examples, but not as the basis for any limitation on the invention.

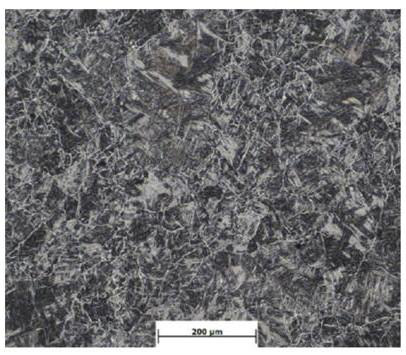

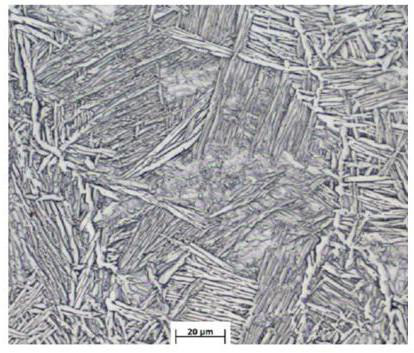

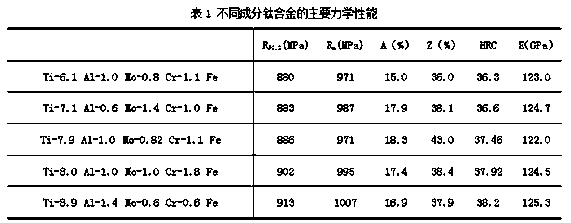

[0016] Sponge titanium, pure aluminum, molybdenum-iron master alloy, and chrome-iron master alloy are prepared into titanium alloy according to weight percentage. The raw materials are uniformly mixed and then extruded into consumable electrodes for smelting. More than one smelting into ingot, melting vacuum degree 0-5Pa, arc voltage 30-40V, arc current 5000-10000A; after smelting, the ingot is prepared into a light ingot for forging by removing the shrinkage cavity and skin of the arc-receiving end; The chemical content is: Ti-(6.0~9.0)Al-(0.6~1.4)Mo-(0.6~1.4)Cr-(0.6~1.8)Fe, using multi-fire forging, and several times of pier forging for each fire The prepared forged slab adopts hot-rolling and cold-rolling processes to prepare a titanium alloy plate for the hitting surface of a golf head.

[0017] The following ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com