Electric vehicle charging device base gangway and quality control

A charging device, electric vehicle technology, applied in electric vehicle charging technology, electric vehicles, charging stations, etc., can solve the problem of loose base and ground, difficult to achieve the standard quality control of mass production and installation, commissioning and use of bridge products , long cycle and other problems, to achieve the effect of loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

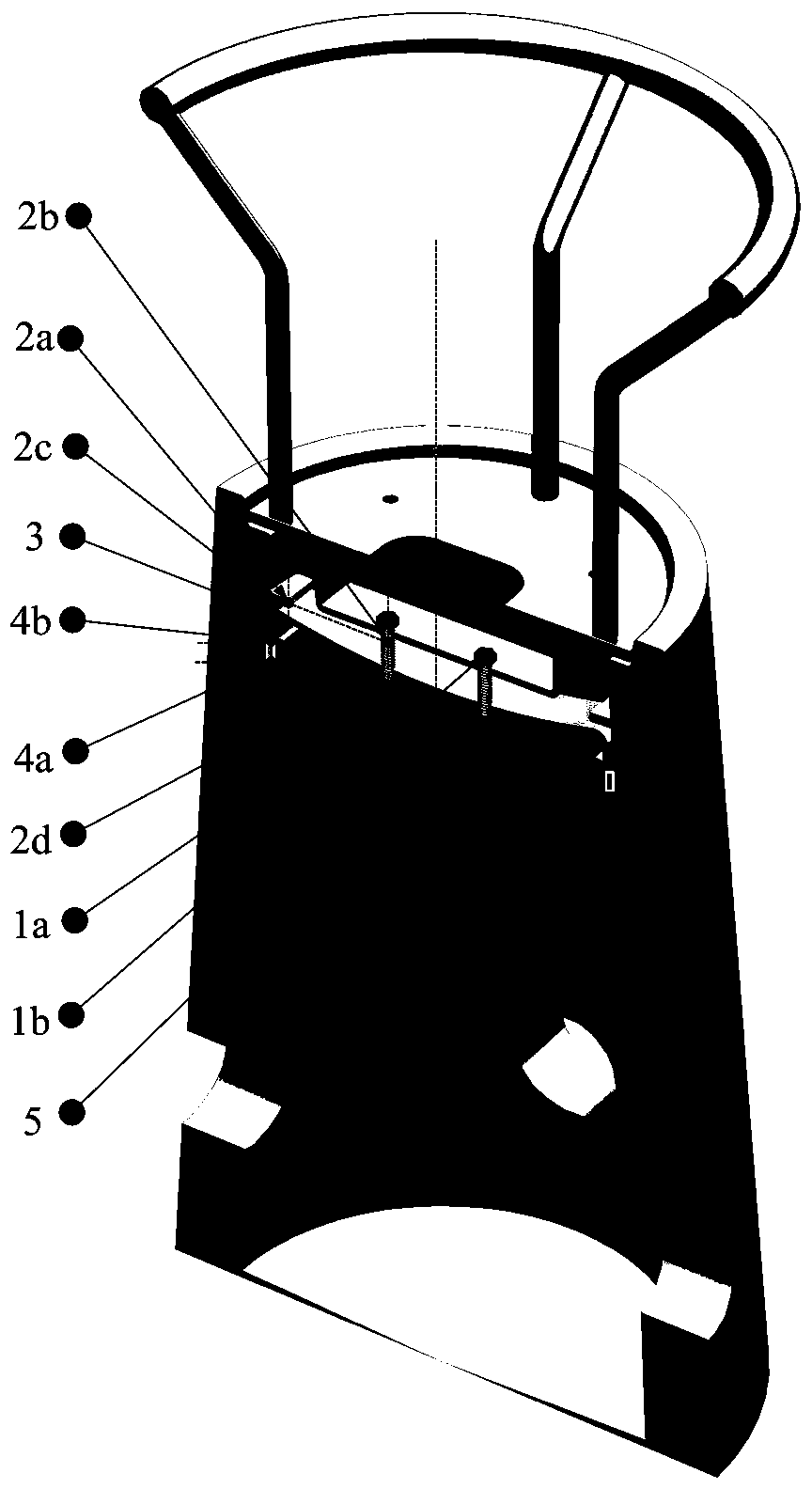

[0014] see figure 1 The preferred embodiment of the electric vehicle charging device base crossing the bridge, this embodiment forms a prestressed tension through the arc-shaped elastic body 1a, and controls the adjusting screw 1b through a torque wrench to realize the initial prestressed tension M0 of the arc-shaped elastic body 1a set up. The required equivalent elastic coefficient K can be achieved through the material, thickness and width of the arc-shaped elastic main body 1a, and the minimum tensile strength of the elastic main body 1a can be realized by setting the distance L between the farthest force point 2a of the bridge lug and the center of the adjusting screw 2b Intensity M=K*L, that is, to achieve the standard quality control of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com