Station monitoring method, computer readable storage medium and system

A computer program and workstation technology, applied in the field of communication protocols, can solve the problems of low information transmission efficiency, cluttered input and output signals, and low control efficiency, and achieve the effects of reducing action lag, improving accuracy, and improving response speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: a method for station monitoring.

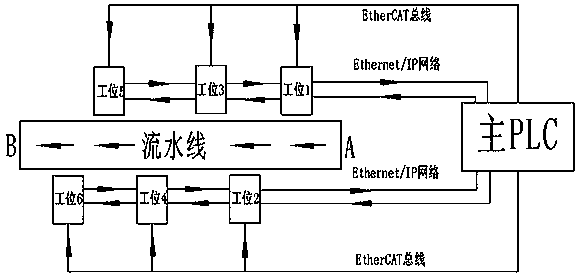

[0020] A method for station monitoring, including a factory assembly line, with flow directions such as figure 1 As shown, from A to B. Set up a main PLC at the beginning of the assembly line, and use the main PLC to monitor each station of the entire assembly line. Stations 1-6 are equipped with 6 remote IO modules, and the output signals can be transmitted to the main PLC through the EtherCAT protocol and the field bus . According to the input signal fed back by the remote IO module, the main PLC calculates the real-time output signal through the program, and feeds back to the remote IO module of each station through the field bus to make the relevant station work. All control signals are transmitted through the on-site EtherCAT bus, and the master PLC has the highest control over each station. The PLC modules of all stations are equipped with network ports, and all data are set as label groups, and the data labels c...

Embodiment 2

[0022] Embodiment 2: a computer-readable storage medium.

[0023] A computer-readable storage medium is used for storing a computer program, and when the computer program is invoked by a processor, the workstation monitoring method of Embodiment 1 is realized.

Embodiment 3

[0024] Embodiment 3: A system.

[0025] A system includes a processor and a memory, the memory is used to store a computer program, and when the computer program is invoked by the processor, the workstation monitoring method of Embodiment 1 is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com