Vertical centrifugal machine for edible mushroom fermented mash based on accelerated settlement zero pasting

A technology of vertical centrifuge and fermented mash, which is applied to centrifuges and centrifuges with rotating drums, etc., can solve the problems of easy sticking of bacterial cells on the inner wall of the machine, slow cleaning efficiency, low separation efficiency, etc. The effect of equipment cleaning and labor saving, ensuring processing quality and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

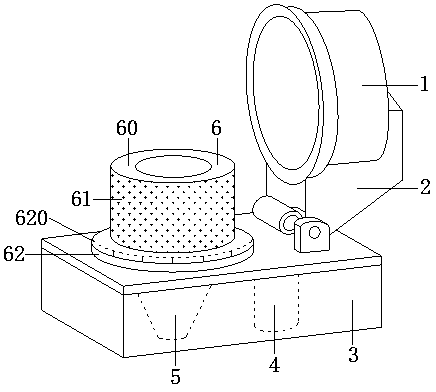

[0029] Example 1 see Figure 1-4 , the present invention provides a technical scheme of a vertical centrifuge for fermentation of edible fungi based on accelerated sedimentation and zero coating: its structure includes a machine cover 1, a welding plate 2, a mounting table 3, a motor 4, a bottom drain 5, and a centrifugal device 6 , the moving roller 31 can drive the welding plate 2 to move back and forth, the forward movement strengthens the reinforcement of the centrifugal device 6 by the welding plate 2 after the hood 1 is turned down, and the backward movement makes the hood 1 lose the reinforcement force, and the turning up is more labor-saving. The hood 1 is welded with the welding plate 2, the welding plate 2 is locked with the installation platform 3, the installation platform 3 is connected with the motor 4, and the bottom drain 5 is installed on the centrifugal device 6 and arranged on the installation platform 3 place, the bottom drain 5 is used for the leakage afte...

Embodiment 2

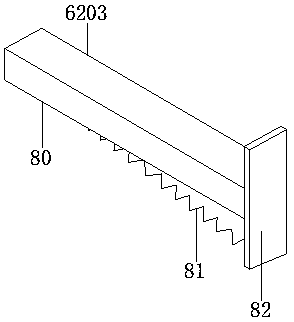

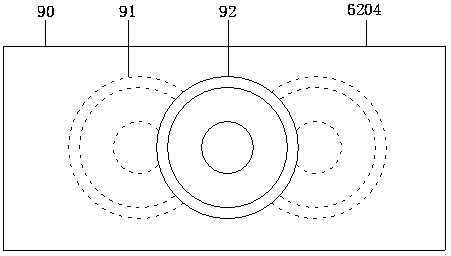

[0031] Example 2 see Figure 5-9, the present invention provides a technical scheme of a vertical centrifuge for edible fungus fermented mash based on accelerated sedimentation and zero coating: its structural column device 611 includes a ladder column 6110, a central column circle 6111, and a telescopic air roller 6112. The ladder column The rotation of 6110 and the center column circle 6111 drives the inertial movement of the hyphae, which plays a driving role. The ladder column 6110 is connected to the center column circle 6111, and the telescopic air roller 6112 is embedded and buckled on the center column circle 6111. The central column circle 6111 plays the role of fixing the telescopic air roller 6112. The telescopic air roller 6112 performs telescopic transmission and generates gas to blow out the hyphae. The structure is compact and the transmission is flexible. The central column circle 6111 includes a circular plate 70, a plate buckle 71, Column buckle 72, the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com