Real-time monitoring and self-adaptive control system and method for tail end running state of numerical control milling machine

An adaptive control and CNC milling machine technology, applied in the direction of manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problems of cutting system instability system failure, tool wear, cutting load increase, etc., to reduce the cost of the enterprise The effect of reducing cost, reducing enterprise operating costs, and increasing enterprise benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is described in more detail.

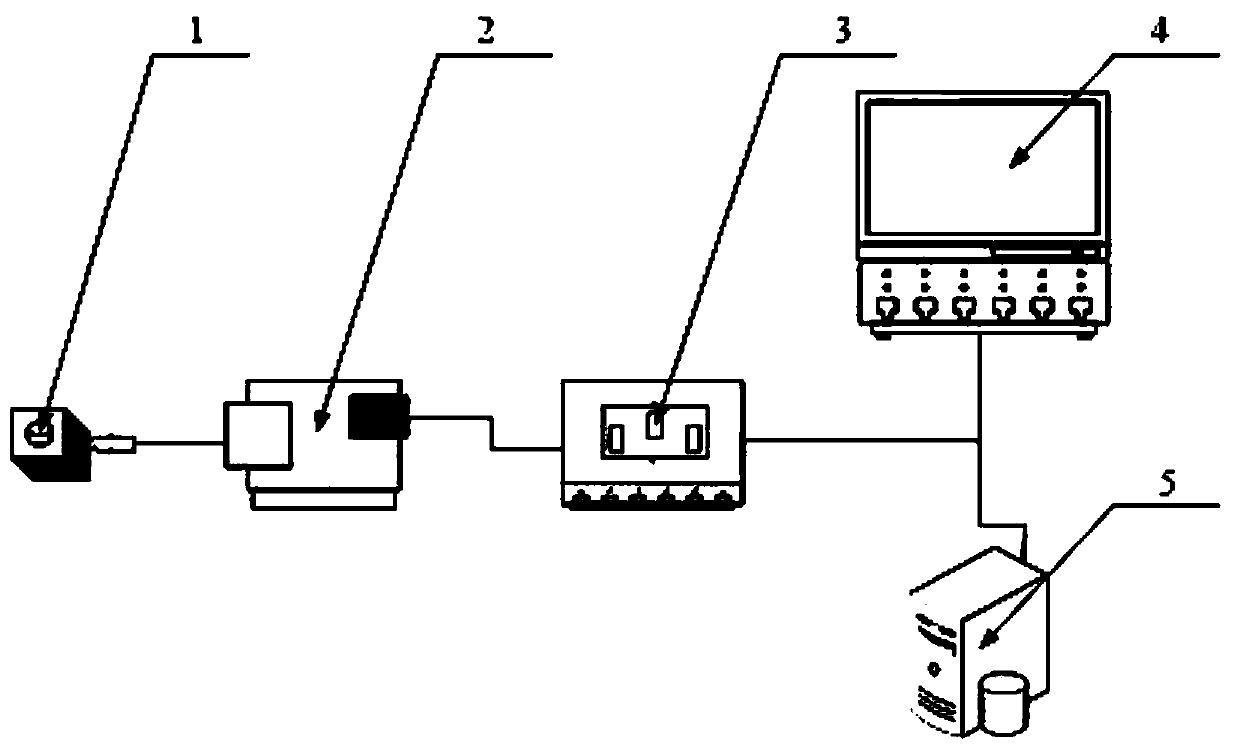

[0022] Such as figure 1 As shown, it is a structural schematic diagram of the real-time monitoring and adaptive control system of the vibration information of the CNC milling machine. The system mainly includes four parts, the vibration sensor 1, the data collector 2, the data analysis processor 3 and the data storage server 5, and the numerical control Milling machine equipment control system4.

[0023] Among them, the vibration sensor 1 adopts a three-way acceleration sensor with a collection frequency of 0.01-10KHz, which is used to collect vibration signals during the cutting process of the machine tool. The vibration sensor can be installed on the end of the spindle or angle milling head by screwing, as close as possible to the rotating tool, so as to collect the vibration signal of the spindle running and tool cutting process more clearly. For some shell segment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com