Efficient preparation method of CuInS2/ZnS semiconductor nanocrystals in cuboid shape

A cuboid and nanocrystal technology is applied in the field of efficient preparation of CuInS2/ZnS semiconductor nanocrystals, which can solve problems such as limiting large-scale production and application, and achieve the effect of enhancing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

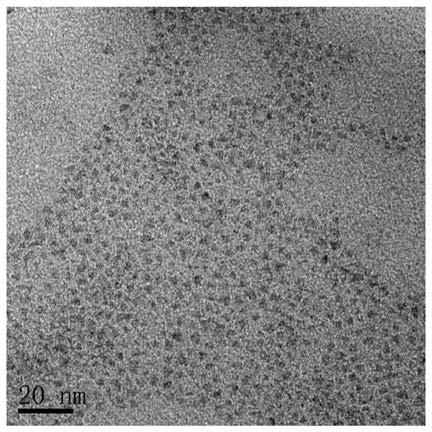

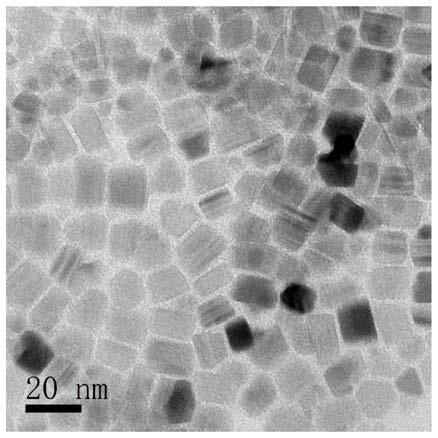

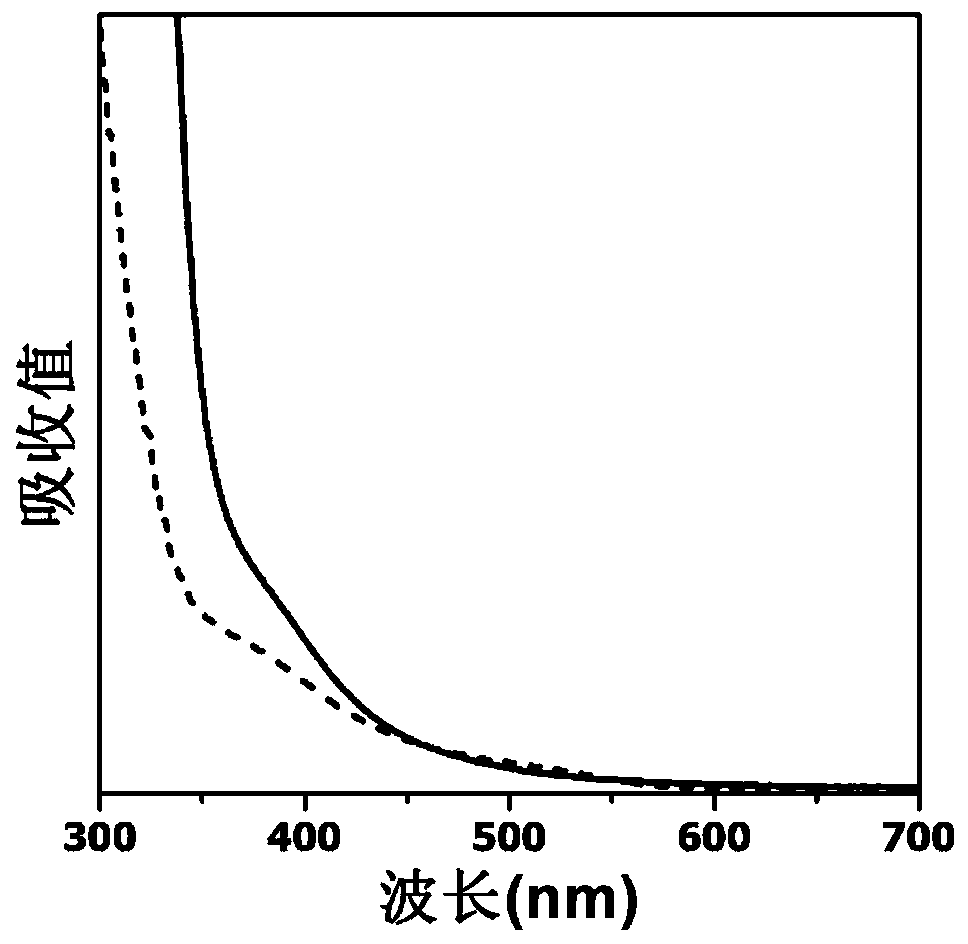

[0022] (1) Preparation of CuInS with an average size of 2.7nm 2 / ZnS nano-nuclei (NCs), purified and dissolved in TOP to obtain a TOP / NCs solution, the concentration of nano-nuclei in the TOP / NCs solution is 45nmol / mL, figure 1 For the obtained CuInS 2 / Transmission electron microscope image of ZnS nanocore, image 3 The dotted line in is the resulting CuInS 2 The absorption spectrum of / ZnS nano-core;

[0023] (2) Under an argon atmosphere, mix sulfur powder with TOP, and sonicate until a clear TOP / S solution is obtained; the concentration of sulfur in the TOP / S solution is 3mol / L;

[0024] (3) Take 10mmol of tri-n-octylphosphine, add 2mmol of ZnO and 10mmol of oleic acid, heat to 130°C for 60 minutes under argon atmosphere, and then raise the temperature to 350°C to make the reactant into a clear solution;

[0025] (4) Inject 2 mL of the TOP / NCs solution in step (1) into the product in step (3), set the temperature at 340 °C, and inject 2 mL of the TOP / S solution in ste...

Embodiment approach 2

[0027] (1) Preparation of CuInS with an average size of 2.5nm 2 / ZnS nano-core (NCs), purified and dissolved in TOP to obtain a TOP / NCs solution, the concentration of the nano-core in the TOP / NCs solution is 52.6nmol / mL;

[0028] (2) Under an argon atmosphere, mix sulfur powder with TOP, and sonicate until a clear TOP / S solution is obtained; the concentration of sulfur in the TOP / S solution is 2.7mol / L;

[0029] (3) Take 9.1 mmol of tri-n-octylphosphine, add 1.8 mmol of ZnO and 9 mmol of oleic acid, heat to 120 °C for 50 minutes under an argon atmosphere, and then raise the temperature to 345 ° C to make the reactant into a clear solution;

[0030] (4) Inject 1.5mL of the TOP / NCs solution in step (1) into the product in step (3), set the temperature at 335°C, and inject the TOP / S solution in step (2) when the temperature returns to 335°C 2.1mL, reacted for 15 minutes and cooled to room temperature to obtain cuboid CuInS 2 / ZnS nanocrystals.

Embodiment approach 3

[0032] (1) Preparation of CuInS with an average size of 3.5nm 2 / ZnS nano core (NCs), purified and dissolved in TOP to obtain a TOP / NCs solution, the concentration of the nano core in the TOP / NCs solution is 40nmol / mL;

[0033] (2) Under an argon atmosphere, mix sulfur powder with TOP, and sonicate until a clear TOP / S solution is obtained; the concentration of sulfur in the TOP / S solution is 4.9mol / L;

[0034] (3) Take 11.6 mmol of tri-n-octylphosphine, add 3 mmol of ZnO and 15.3 mmol of oleic acid, heat to 125 under an argon atmosphere and react for 55 minutes, then raise the temperature to 348° C. to make the reactant into a clear solution;

[0035] (4) Inject 2.5 mL of the TOP / NCs solution in step (1) into the product in step (3), set the temperature at 3370°C, and inject the TOP / S solution in step (2) when the temperature returns to 337°C 1.9mL, reacted for 16 minutes and cooled to room temperature to obtain cuboid CuInS 2 / ZnS nanocrystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com