A preparation method for a transparent superhydrophobic coating on the surface of a hydrophilic core

A super-hydrophobic coating and hydrophilic technology, applied in the field of material science, can solve the problems of high cost, no consideration of scientific research interference of thick layer pouring liquid, serious environmental pollution, etc., and achieves low price, excellent protection performance, and preparation technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

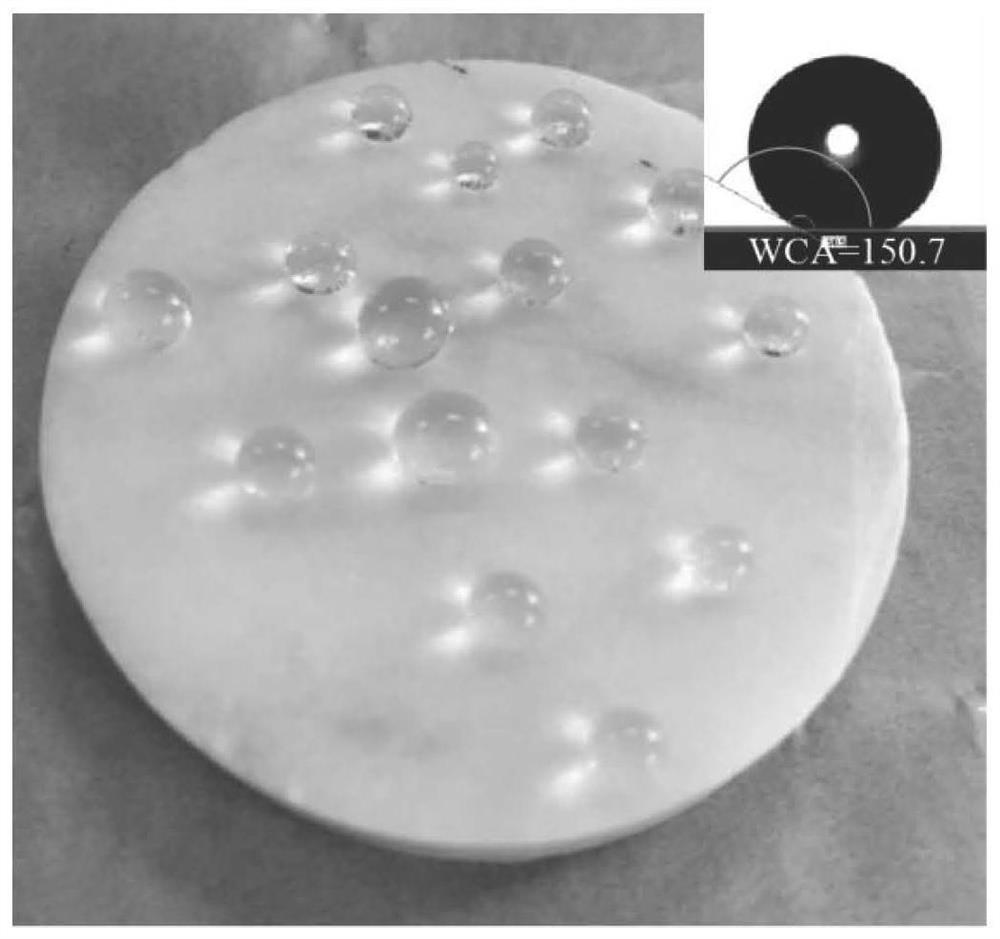

[0028] The invention provides a method for preparing an ultra-thin visible super-hydrophobic protective layer on the surface of a hydrophilic rock core, which prevents the weathering of the rock core and achieves a good protection effect. Specifically include the following steps:

[0029] 1) Core surface pretreatment: The main component is CaMg(CO 3 ) 2 Take the hydrophilic rock core as an example. After rinsing the surface of the core with clean water, air-dry it for later use. Configure a 1wt% cetyltrimethylammonium bromide solution at 40°C, and then evenly spray ten Hexaalkyltrimethylammonium bromide solution, let stand for 20s, repeat spraying 3 times, air dry, then rinse with water and air dry for use.

[0030] 2) Prepare modified silica solution: weigh 1g of sodium fluorosilicate and 0.2g of potassium silicate, add 90ml of deionized water and stir to dissolve, then add 0.3g of boric acid and stir for 1h, and finally add 0.1g of boric acid dissolved in 10ml of ethanol ...

Embodiment 2

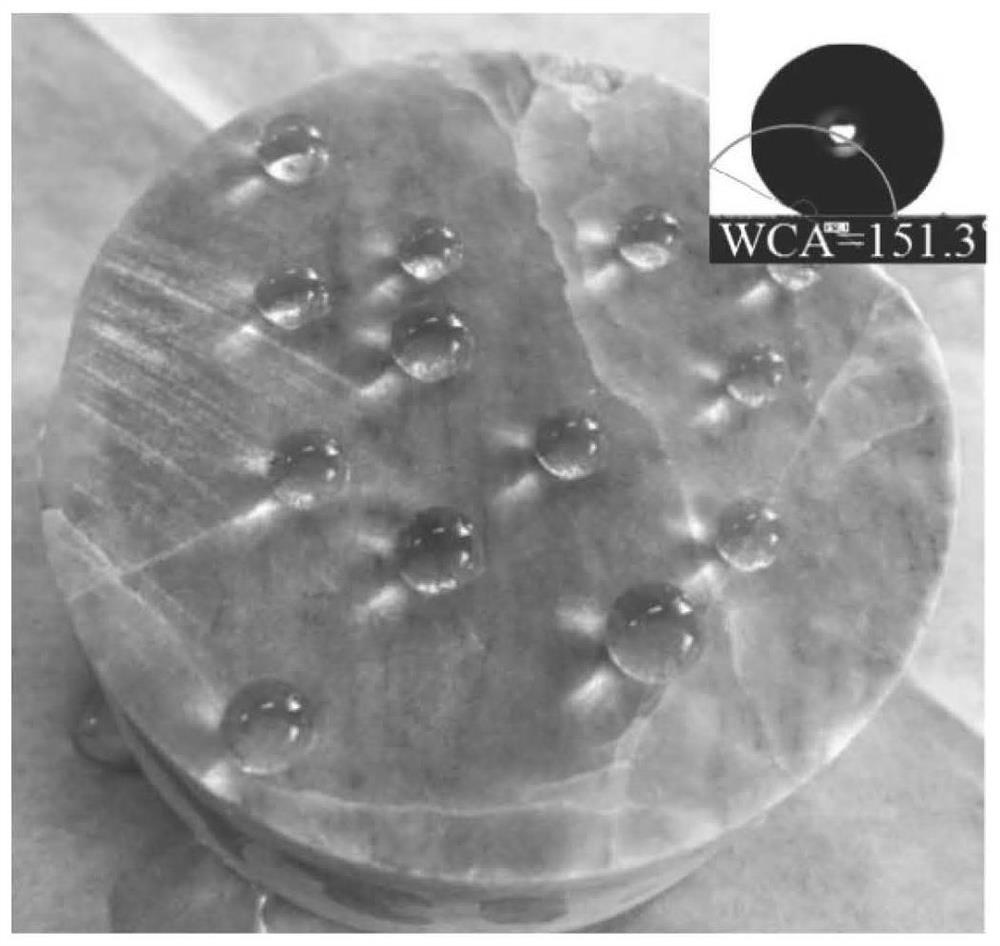

[0037] 1) Core surface pretreatment: The main component is CaMg(CO 3 ) 2 Take the hydrophilic rock core as an example, clean the rock core with clean water, let it dry naturally, and prepare it as a 2wt% cetyltrimethylammonium bromide solution at 35°C, and then evenly spray ten Hexaalkyltrimethylammonium bromide solution, let it stand for 30s, repeat spraying 3 times, after natural air drying, rinse with water and air dry for use.

[0038] 2) Configure hydrophobic silica modified sol solution: weigh 0.6g sodium fluorosilicate and 0.5g potassium silicate, add 90ml deionized water and stir to dissolve, then add 0.1g boric acid and stir for 1 hour, finally add 10ml ethanol to dissolve 0.2 g of hydroxyl-terminated polydimethylsiloxane, stirred evenly to form a sol.

[0039] 3) Evenly spray hydrophobic silica-modified sol solution on the surface of the rock core treated with cetyltrimethylammonium bromide, let it stand for 30 seconds, repeat the spraying 6 times, leave it for 1 d...

Embodiment 3

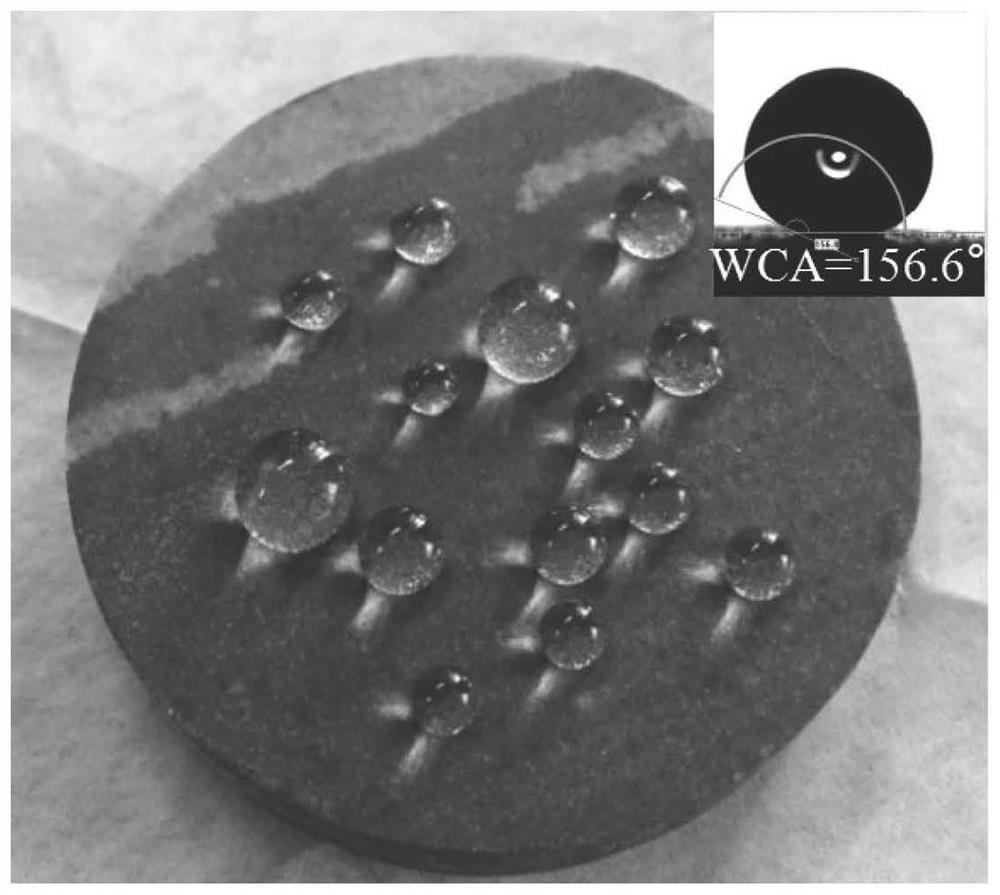

[0041] 1) Core surface pretreatment: The main component is CaMg(CO 3 ) 2 Take the hydrophilic rock core as an example, clean the rock core with clean water, let it dry naturally, and prepare a 3wt% cetyltrimethylammonium bromide solution at 30°C, and then evenly spray ten Hexaalkyltrimethylammonium bromide solution, let it stand for 20s, repeat spraying twice, after natural air drying, rinse with water and air dry for use.

[0042] 2) Configure hydrophobic silica modified sol solution: weigh 0.8g sodium fluorosilicate and 0.3g potassium silicate, add 90ml deionized water and stir to dissolve, then add 0.2g boric acid and stir for 1 hour, finally add 10ml ethanol to dissolve 0.3 g of hydroxyl-terminated polydimethylsiloxane solution, stirred evenly to form a sol.

[0043] 3) Evenly spray hydrophobic silica-modified sol solution on the surface of the rock core treated with cetyltrimethylammonium bromide, let it stand for 20 seconds, and repeat the spraying 4 times. After 1 day o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com