Environment-friendly MS sealant and preparation method thereof

A MS sealant, environmentally friendly technology, applied in the direction of adhesives, adhesive types, polyether adhesives, etc., can solve the problem of low bonding strength, achieve fast curing strength, shorten curing and tack-free time, and low TVOC Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

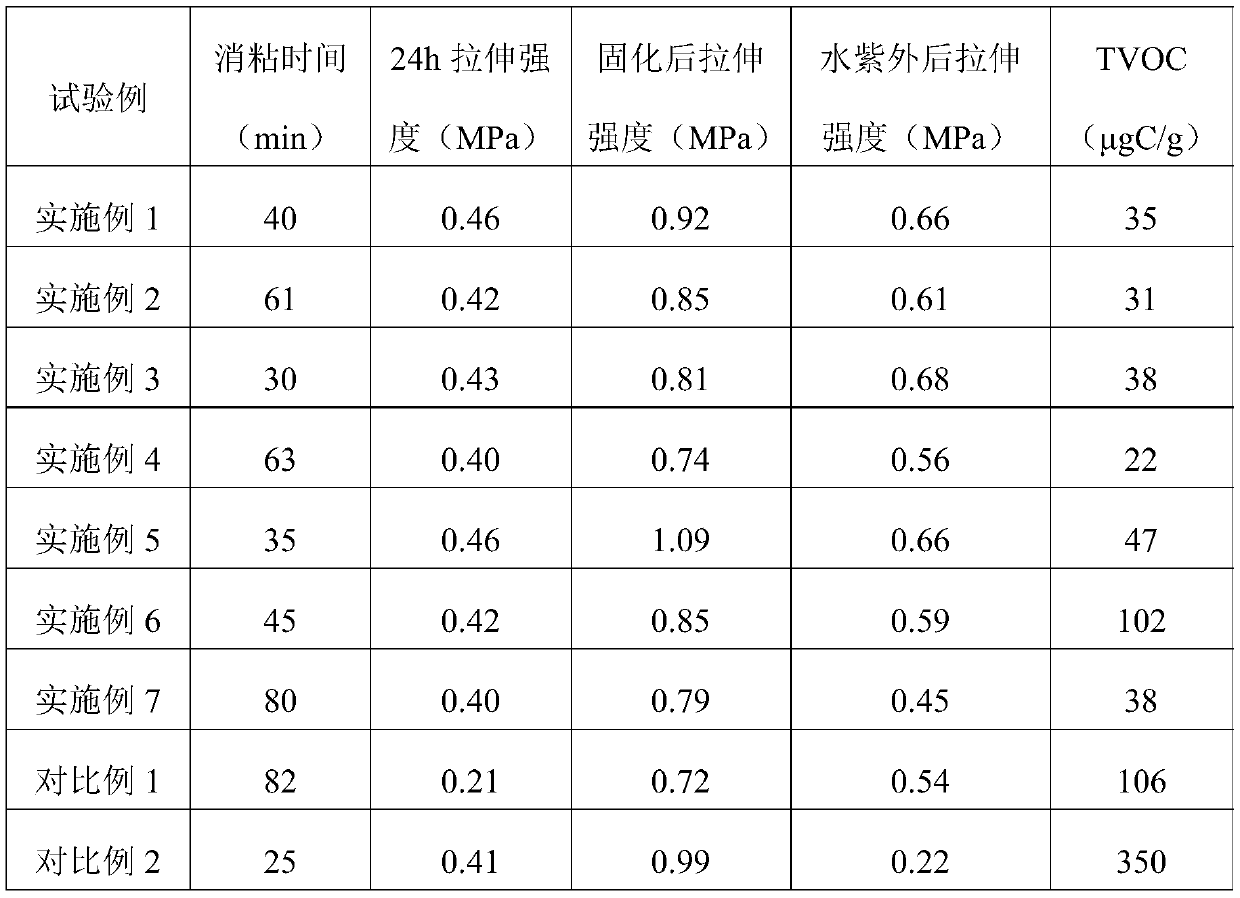

Examples

Embodiment 1

[0047] This embodiment provides an environment-friendly MS sealant, including component A and component B. Among them, component A is prepared from the following raw materials in parts by weight: 100 parts of trialkoxy-terminated silane-modified polyether prepolymer (Ruiyang Litai 12000DS), 180 parts of nano-calcium carbonate, 100 parts of heavy Calcium carbonate, 65 parts of polyether 2000, 1 part of UV absorber Tinuvin326, 1 part of light stabilizer Tinuvin770DF and 30 parts of JLVC-1 molecular sieve;

[0048] Component B is prepared from the following raw materials in parts by weight: 100 parts of polyether 2000, 50 parts of U carbon black, 70 parts of anti-aging silane additive and 2.5 parts of chelated tin.

[0049] The preparation method of the environment-friendly MS sealant of the present embodiment comprises the following steps:

[0050]Preparation of component A: Weigh the raw materials according to the composition of component A, and mix trialkoxy terminated silane...

Embodiment 2

[0053] This embodiment provides an environment-friendly MS sealant, including component A and component B. Among them, component A is prepared from the following raw materials in parts by weight: 60 parts of trialkoxy terminated silane modified polyether prepolymer (Ruiyang Litai 12000DS), 40 parts of dialkyl terminated silane modified Polyether polymer (S810), 160 parts of nano calcium carbonate, 110 parts of heavy calcium carbonate, 70 parts of polyether 2000, 1 part of ultraviolet absorber Tinuvin326, 1 part of light stabilizer Tinuvin770DF and 40 parts of JLVC-1 molecular sieve;

[0054] Component B is prepared from the following raw materials in parts by weight: 100 parts of polyether 2000, 50 parts of U carbon black, 70 parts of anti-aging silane additive and 2.5 parts of dibutyltin dilaurate.

[0055] The preparation method of the environment-friendly MS sealant of the present embodiment comprises the following steps:

[0056] Preparation of component A: Weigh each raw...

Embodiment 3

[0059] This embodiment provides an environment-friendly MS sealant, including component A and component B. Among them, component A is prepared from the following raw materials in parts by weight: 100 parts of trialkoxy-terminated silane-modified polyether prepolymer (Ruiyang Litai 12000DS), 180 parts of nano-calcium carbonate, 100 parts of heavy Calcium carbonate, 65 parts of polyether 2000, 2 parts of UV absorber Tinuvin326, 2 parts of light stabilizer Tinuvin770DF and 30 parts of JLVC-1 molecular sieve;

[0060] Component B is prepared from the following raw materials in parts by weight: 100 parts of polyether 2000, 50 parts of U carbon black, 70 parts of anti-aging silane additive and 2.5 parts of dibutyltin dilaurate.

[0061] The preparation method of the environment-friendly MS sealant of the present embodiment comprises the following steps:

[0062] Preparation of component A: Weigh the raw materials according to the composition of component A, and mix trialkoxy-termin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap