Novel UHPC light composite beam

An ultra-high-strength concrete beam technology, applied in the field of composite beams, can solve problems such as weak compressive capacity and reduced service life of composite beams, achieve good flexural strength and compressive strength, improve compressive strength, and improve system crossover joint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

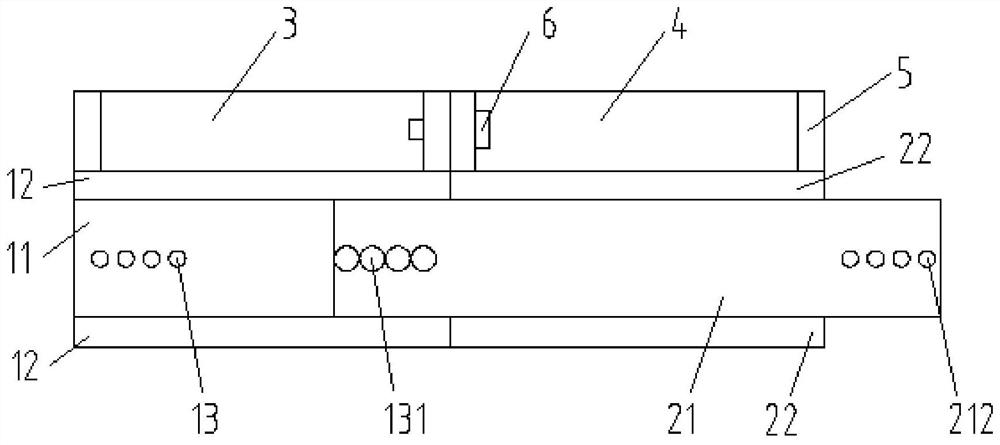

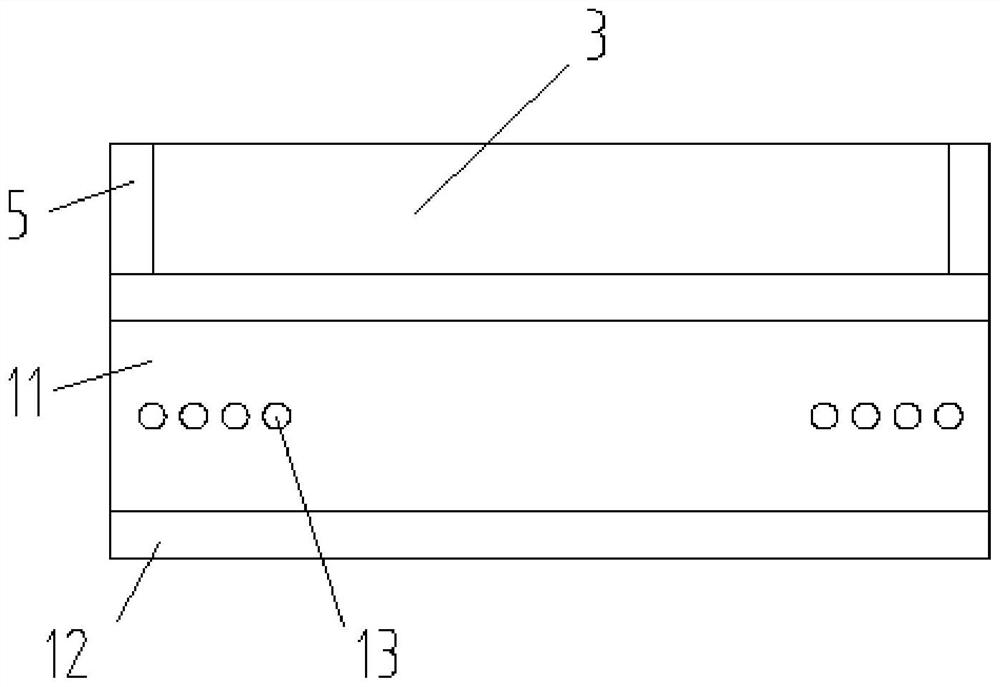

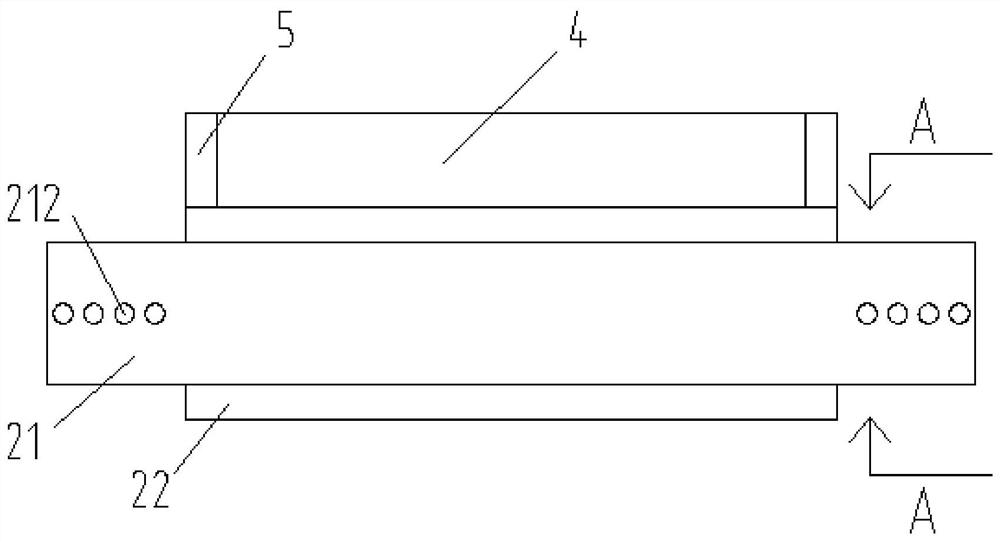

[0036] like Figure 1-Figure 5 As shown, the novel ultra-high-strength concrete UHPC light composite beam provided by the present invention includes a first beam body and a second beam body, and the first beam body includes a first vertical plate 11 and two square first support plates 12, The first vertical plate 11 is welded and fixed between the two first support plates 12, and the first concrete beam 3 is placed horizontally on the upper side of the first support plate 12; the second beam body includes two parallel arranged second vertical plates 21 and two A square second support plate 22, two second vertical plates 21 are welded and fixed between the two second support plates 22, and the second concrete beam 4 is placed horizontally on the upper side of the second support plate 22. Both sides of the two second vertical plates 21 protrude from the outside of the two second supporting plates 22 , a connecting channel 211 is formed between the two second vertical plates 21 ,...

Embodiment 2-1

[0056] The preparation method of the first concrete beam or the second concrete beam, the steps are as follows:

[0057] (1) Add 100 parts of Portland cement, 50 parts of fly ash, 3 parts of expansion agent, 10 parts of silica fume, 60 parts of quartz sand, 30 parts of steel fiber, and 60 parts of aggregate into the mixer, at 200r / min After fully mixing for 100 seconds, a mixture is obtained;

[0058] (2) 3 parts of water reducing agents are added to 30 parts of water, and after fully mixing, mixture two is obtained;

[0059] (3) 1 part of amino-containing polybenzimidazole is added to 5 parts of dimethyl sulfoxide, and after fully dissolving, mixture three is obtained;

[0060] (4) 1 part of sulfonated polyphenylene and 1 part of KH-560 are added to 10 parts of ethanol, and after fully mixing, mixture four is obtained;

[0061] (5) After fully mixing the above-mentioned mixtures one, two, three and four at 200 r / min at 50 ° C for 150 seconds, the ultra-high performance conc...

Embodiment 2-2

[0064] The preparation method of the first concrete beam or the second concrete beam, the steps are as follows:

[0065] (1) Add 100 parts of Portland cement, 54 parts of fly ash, 7 parts of expansion agent, 13 parts of silica fume, 77 parts of quartz sand, 35 parts of steel fiber, and 78 parts of aggregate into the mixer, at 200r / min After fully mixing for 100 seconds, a mixture is obtained;

[0066] (2) 6 parts of water reducing agents are added to 65 parts of water, and after fully mixing, mixture two is obtained;

[0067] (3) 3 parts of amino-containing polybenzimidazoles are added to 8 parts of dimethyl sulfoxide, and after fully dissolving, mixture three is obtained;

[0068] (4) 3 parts of sulfonated polyphenylene and 4 parts of KH-560 are added to 12 parts of ethanol, and after fully mixing, mixture four is obtained;

[0069] (5) After fully mixing the above-mentioned mixtures one, two, three and four at 200 r / min at 50 ° C for 150 seconds, the ultra-high performance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap