Light one-way loading test device and application thereof

A loading test device, one-way technology, applied in the direction of measuring device, using applied stable tension/pressure to test material strength, using wave/particle radiation for material analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

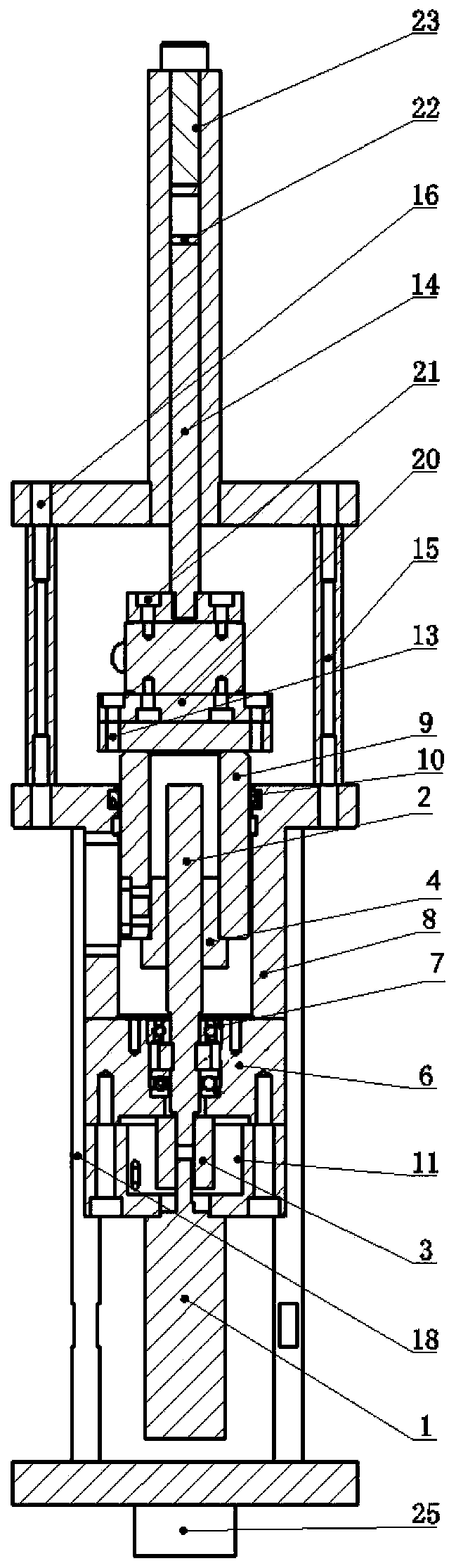

[0049] The total height of the test device is 526mm (excluding the bottom connection plate), the maximum outer diameter is 120mm, and the maximum loading force is 1kN. The main material of the device is mainly 304 stainless steel, with a total weight of about 6kg; the bottom connection plate can be used with a three-jaw chuck to fix the device. The diameter of the connection plate is 35mm and the height is 18mm, which can be customized according to the size of the specific three-jaw chuck Land.

[0050] The sample sleeve is a PEEK tube with an outer diameter of 25mm, an inner diameter of 10mm, and an effective height of 143mm. The height of the sample loading area reserved inside is 20mm. The loading force is above 8KN and can meet the stability requirements during loading. In order to eliminate the metal artifacts existing in the CT scanning process, PEEK contact caps can be installed on the upper and lower sides of the sample loading area through prefabricated threads to sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com