Method for grading quality of alfalfa hay by using near-infrared method experimental data

An experimental data, alfalfa hay technology, applied in the direction of material analysis by optical means, preparation of test samples, analysis of materials, etc. Reduce the amount of operation, facilitate sampling, and promote the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

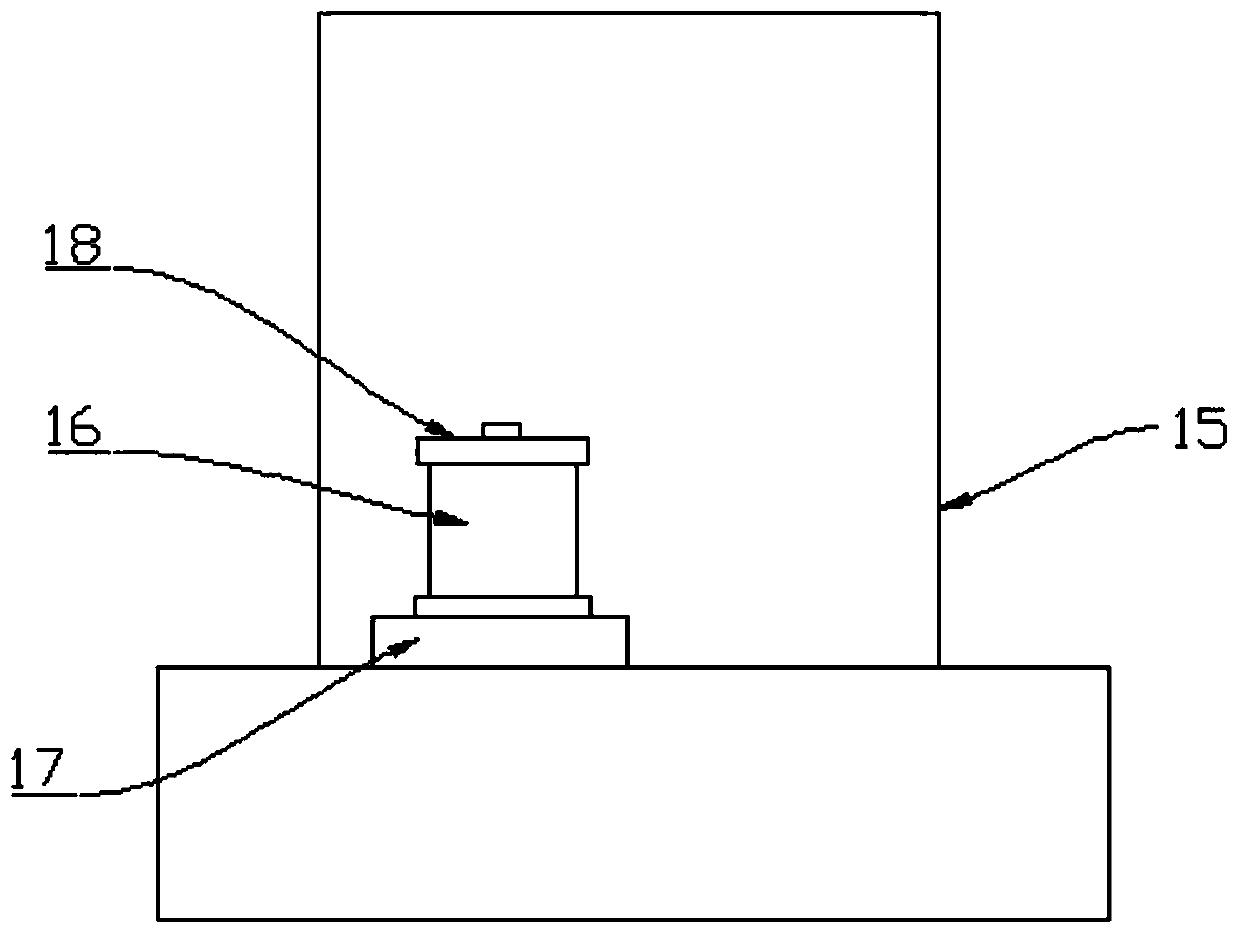

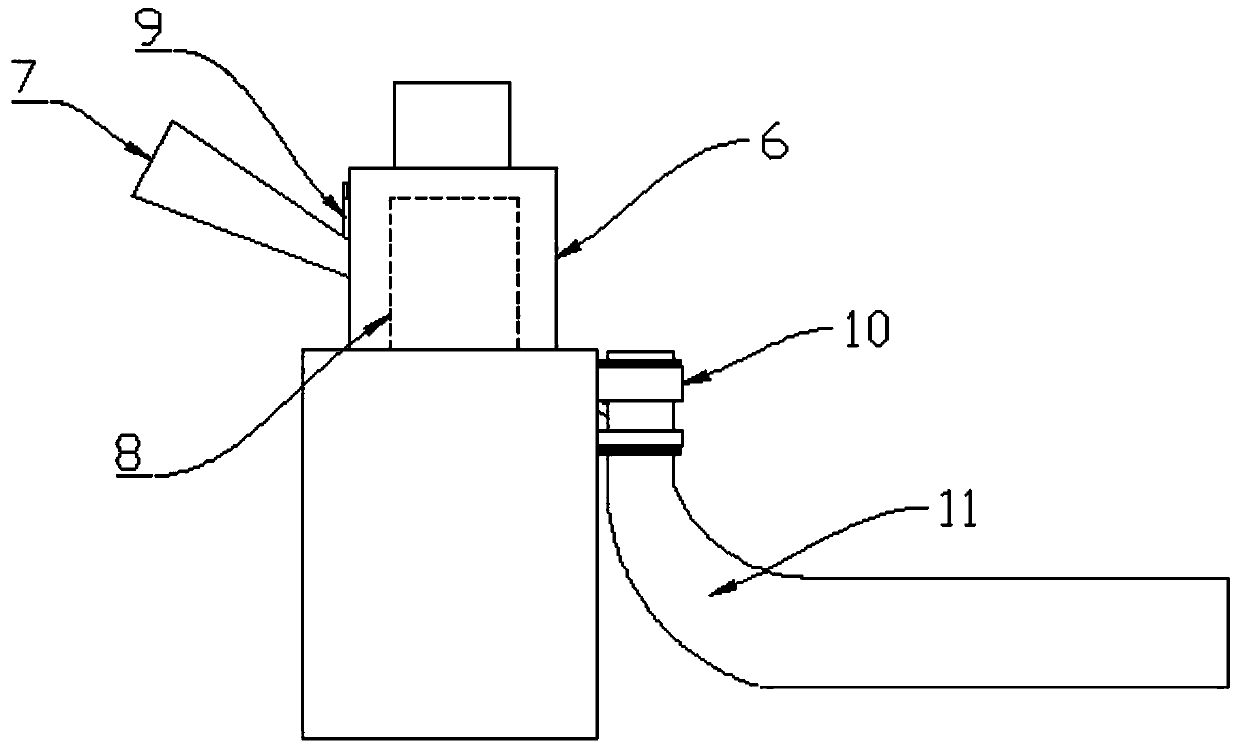

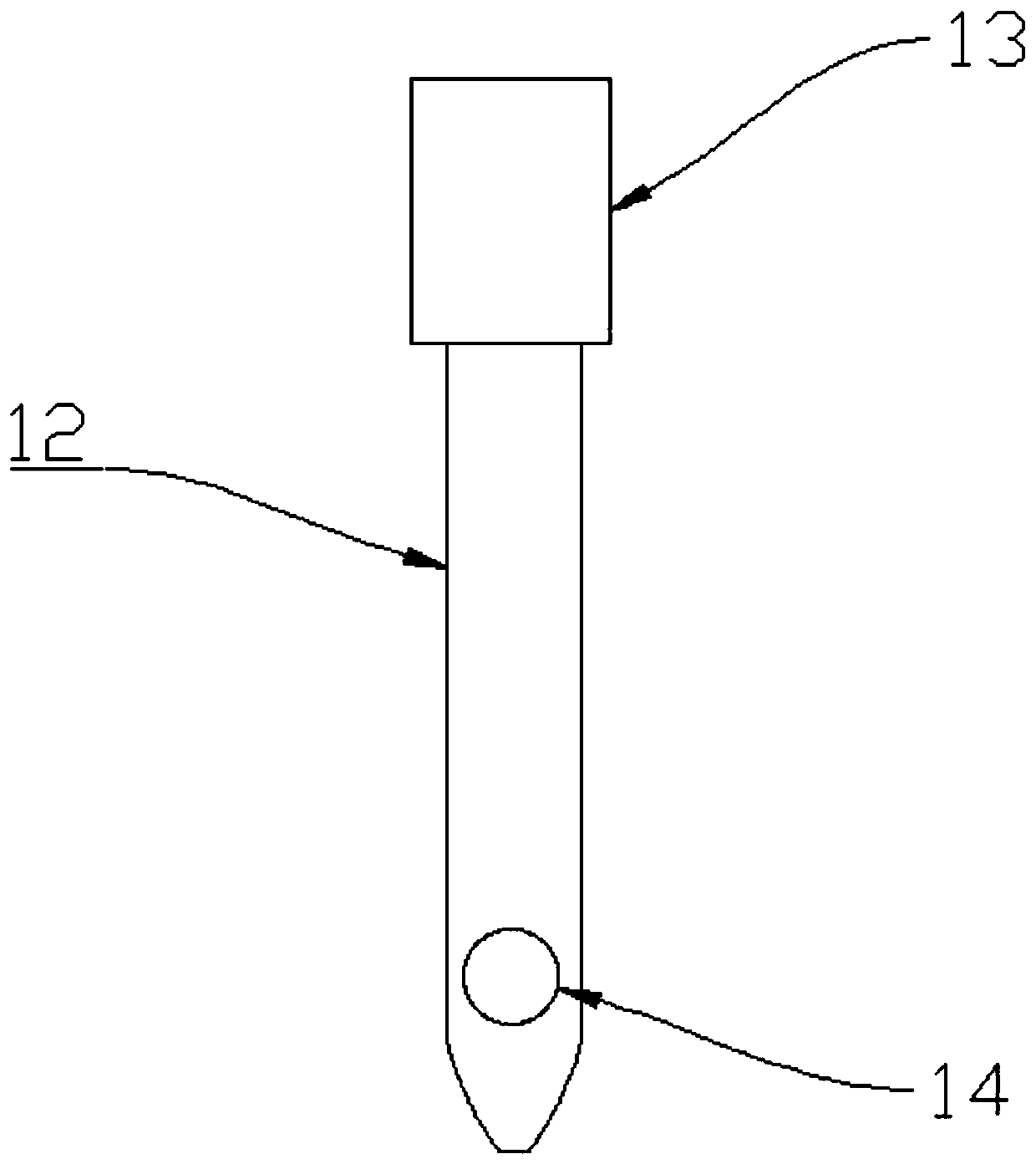

[0027] Such as figure 1 To such as Figure 4 As shown, a method for grading the quality of alfalfa hay using the experimental data of the near-infrared method includes a sampling step, a powder sample step and a detection step. It includes a sampling tube 1, a handle 2, a sampling chamber 3, a storage bottle 4 and a sampler body 5, the sampling chamber 3 is arranged inside the sampler body 5, and the rear end of the sampling tube 1 is detachably connected to the sampler body 5, which can be passed through The rotation of the sampling tube 1 completes the disassembly of the sampling tube 1, thereby facilitating the replacement of the sampling tube 1. The rear end of the sampling tube 1 goes deep into the interior of the sampler body 5 and communicates with the sampling cavity 3. There are two handles 2 and are respectively arranged on the sampler. On the left and right sides of the main body 5, the storage bottle 4 is located at the rear end of the sampler main body 5 and is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com