Oil sludge cleaning device and oil sludge cleaning vehicle

A technology for cleaning devices and oily sludge, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as hidden safety hazards, time-consuming and labor-intensive problems, and achieve improved operation efficiency, safety and reliability, and investment The effect of less manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

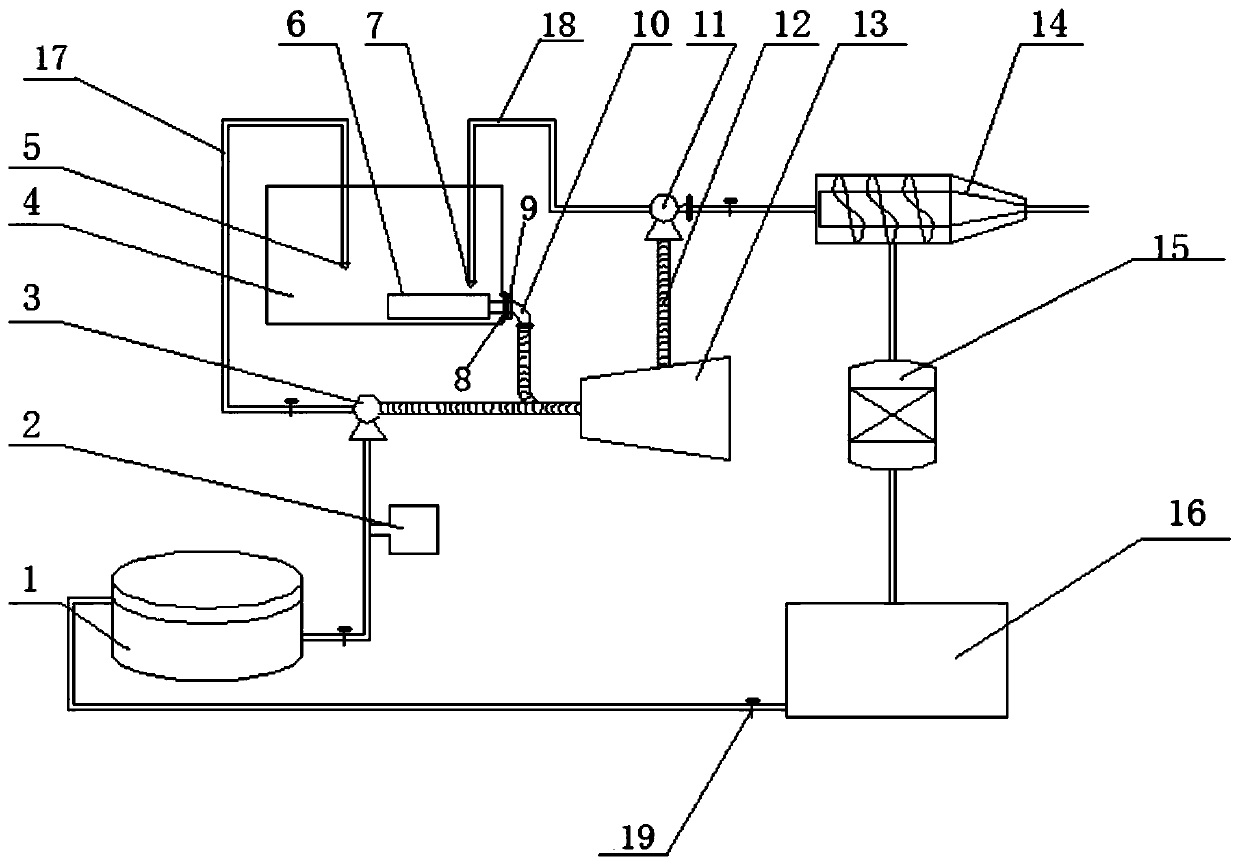

[0038] Such as figure 1 As shown, an oil sludge cleaning device includes an oil sludge cleaning device including an air compressor 13, a water supply tank 1, a jet pump 3, a vacuum dredging pump 11, an air flotation component 6, a dosing tank 2, and a dehydration component 14. Sewage purifier 15 and recovery pool.

[0039] The air compressor is connected with the jet pump 3 , the vacuum desilting pump 11 and the air flotation unit 6 through the soft rubber hose 12 to provide the power source for the three.

[0040] Water supply tank 1 links to each other with jet pump 3 by pipeline, provides water source for jet pump 3; Jet pump 3 carries out high-pressure water jet flushing to treat container 4 by first pipeline 17, and the end of first pipeline 17 is provided with nozzle, can increase Great impact.

[0041] The dosing tank 2 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com