Turning device used for barrel type part inner hole multi-end spiral groove

A technology for spiral grooves and parts, which is applied in the field of turning devices for multi-head spiral grooves in inner holes of cylindrical parts, and can solve the problems of long processing time and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

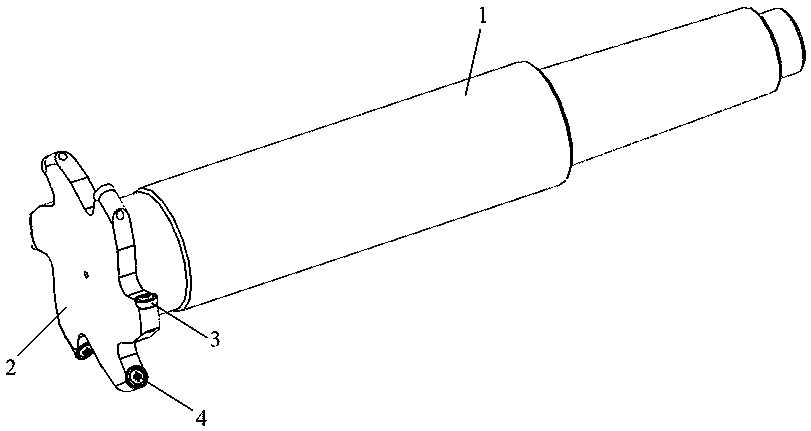

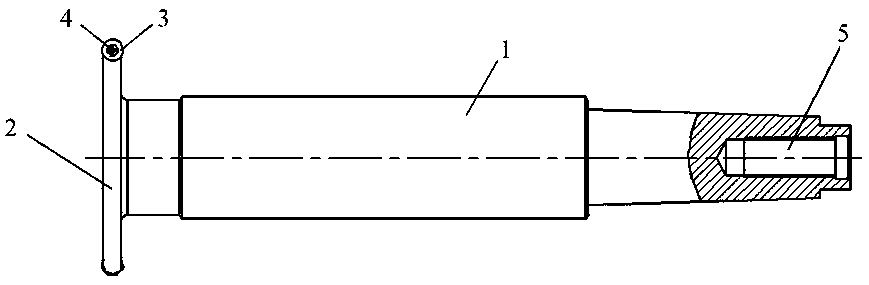

[0025] Such as figure 1 , 2 As shown, a turning device for multi-start spiral grooves in inner holes of cylindrical parts includes a milling cutter body and a plurality of milling blades 3 .

[0026] The milling cutter body consists of a milling shank 1 and a milling head 2 connected to each other.

[0027] The milling cutter bar 1 has a stepped shaft structure, and a threaded blind hole 5 is formed on the end face away from the milling head 2; the threaded blind hole 5 is used to realize the threaded connection between the milling cutter bar 1 and the output shaft of the machine tool motor. The milling cutter bar 1 is composed of a connecting section, a middle section and a tail section which are connected in sequence. The tail section is a truncated circular structure whose diameter gradually decreases from the head end to the tail end, and an annular groove is formed on the outer circumference of the small diameter end. The connecting section is connected with the milling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com