A transfer printing process method for flexible mems devices

A process method and flexible technology, applied in the field of semiconductor/MEMS manufacturing process, can solve the problems of long release time, device structure failure, high requirements for accurate transfer temperature and time, etc., to enhance adhesion and improve transfer success. rate, the effect of shortening the release time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

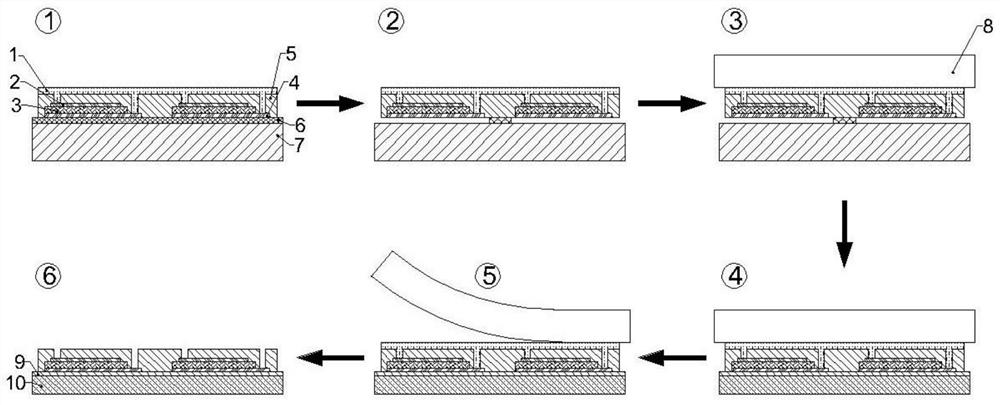

[0021] A transfer printing process method for flexible MEMS devices, the specific steps are as follows:

[0022] step one, as figure 1 As shown in step ①, a layer of SiN is deposited by PECVD on the cleaned 2-inch monocrystalline silicon wafer X sacrificial layer film, where NH 3 and SiH 4 The injection ratio of TiO was 8:1, the reaction temperature was 450 °C, the reaction pressure was 160 Pa, and the deposition rate was 1 nm / s. After the deposition is completed, the thickness is measured. In this example, SiN X The thickness of the sacrificial layer is 0.8 μm;

[0023] Step two, as figure 1 As shown in step ①, the SiN X The bottom electrode Ti(50nm) / Pt(200nm)-PZT(500nm)-upper electrode Cr(10nm) / Au(100nm) three-layer device structure was fabricated on the sacrificial layer. 600r / min, glue mixing time 9s, high speed 3000r / min, glue mixing time 30s), pre-baking (temperature is 120℃, time is 3min), nitrogen oven curing (curing adopts step drying, the temperature is 50℃, 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com