Bifunctional polyester resin for super-weather-resistant heat transfer printing powder coating and preparation method thereof

A technology of powder coating and polyester resin, which is applied in the direction of powder coating, polyester coating, coating, etc., which can solve the problems of high weather resistance, high acid value and other coating requirements, and achieve good heat transfer printing Effect of performance and/or leveling, reduced dosage, improved weatherability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

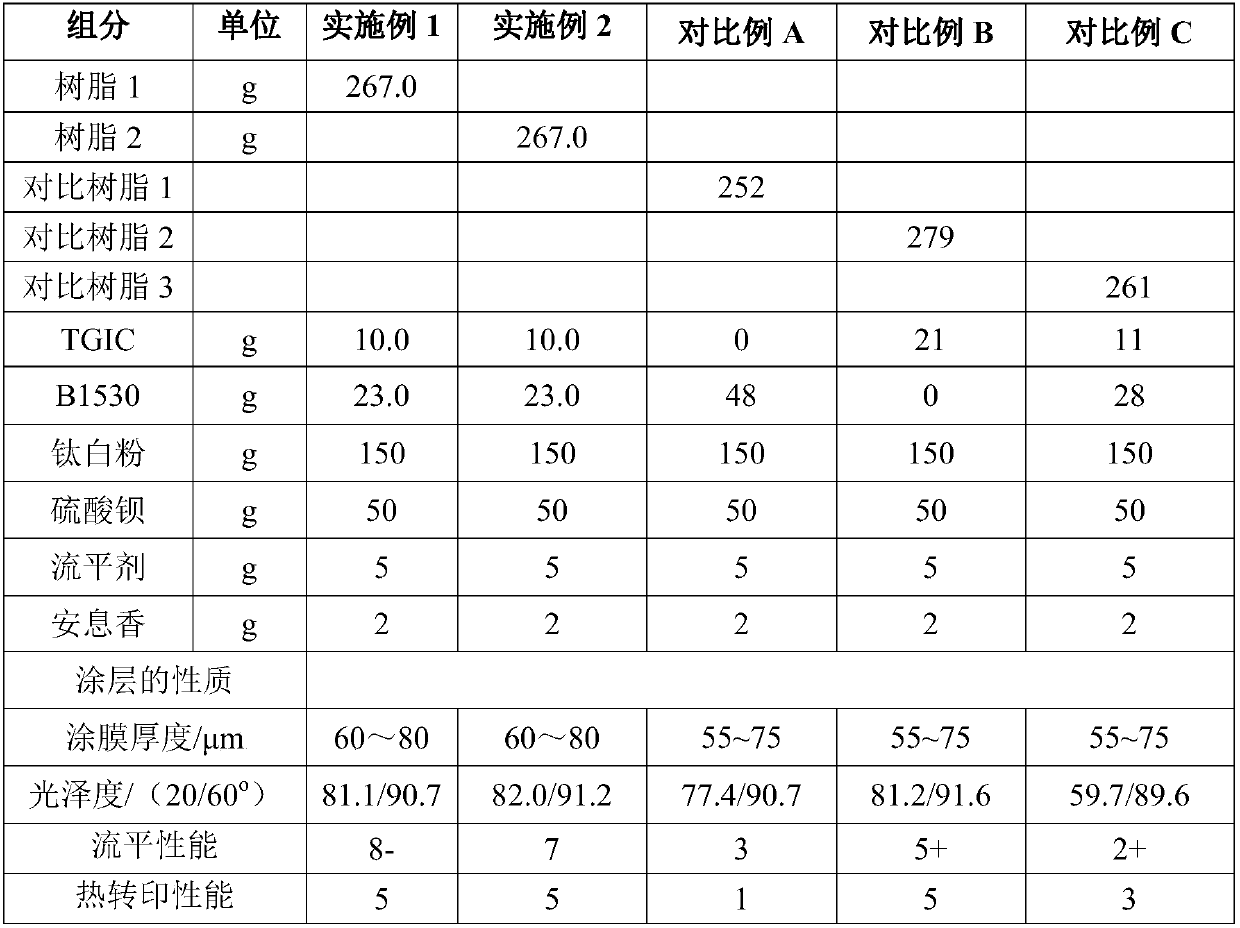

Examples

preparation example Construction

[0033] Preparation method of bifunctional polyester resin

[0034] The difunctional polyester resins described above can be prepared by a variety of methods. For example, a kind of exemplary preparation method comprises the following steps: polyhydric alcohol, polybasic acid, branching agent, and optional esterification catalyst are mixed and heated to carry out esterification polycondensation reaction; Then control reaction system at given temperature In case of adding an acidolysis agent or an alcoholysis agent, carry out further esterification reaction; control the acid value within a given range, then vacuum polycondensation until a resin product within the predetermined acid value and hydroxyl value range is obtained; optionally, Add additives such as antioxidants.

[0035] Therefore, another aspect of the present invention also relates to a method for preparing the difunctional polyester resin according to the present invention, comprising:

[0036] The following rea...

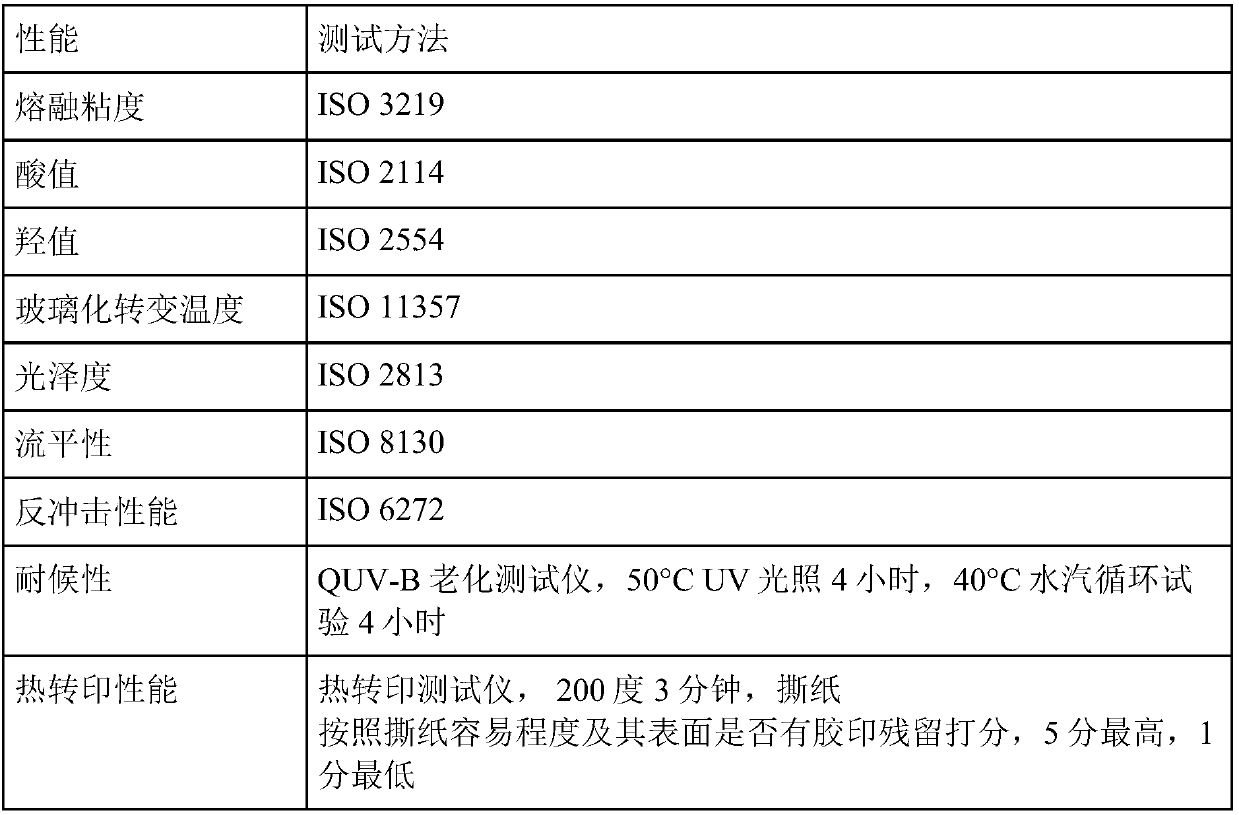

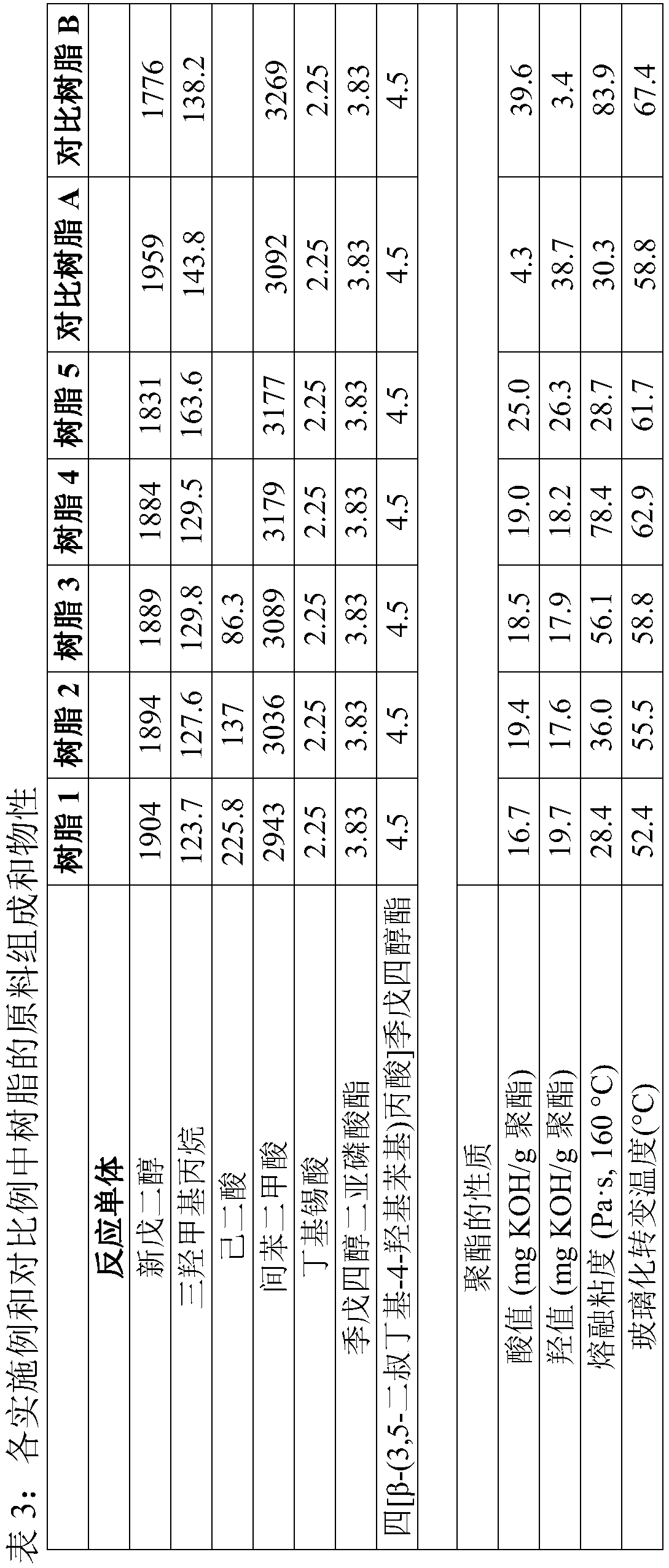

Embodiment 1-2 and comparative example A-C

[0099] Examples 1-2 and Comparative Examples A-C: Powder Coating Compositions

[0100] Prepare powder coatings by following steps:

[0101] 1. Premix all the raw materials polyester, curing agent, leveling agent, pigment and defoamer used in the manufacture of powder coatings in the premixer;

[0102] 2. Melt and extrude the pre-mixed raw materials through the extruder;

[0103] 3. Cool and press the molten extruded material into tablets;

[0104] 4. The flakes are pulverized by a pulverizer and sieved to obtain powder particles with a suitable particle size, which is the powder coating.

[0105] Respectively use Resin 1, Resin 2, Comparative Resin 1, Comparative Resin 2 and Comparative Resin 3 (1:1 mixture of Comparative Resin 1 and Comparative Resin 2) as raw material polyester to prepare powder coatings and measure the properties of the coating .

[0106]

[0107] It can be seen from the above results that the coating composition formulated with the bifunctional po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com