Real stone paint and preparation method thereof

A technology of real stone paint and natural colored sand, used in paints, coatings, anti-corrosion coatings, etc. containing biocides, can solve the problems of low repairability, high construction cost, cracks, etc., achieve excellent weather resistance, reduce construction The effect of heavy load and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

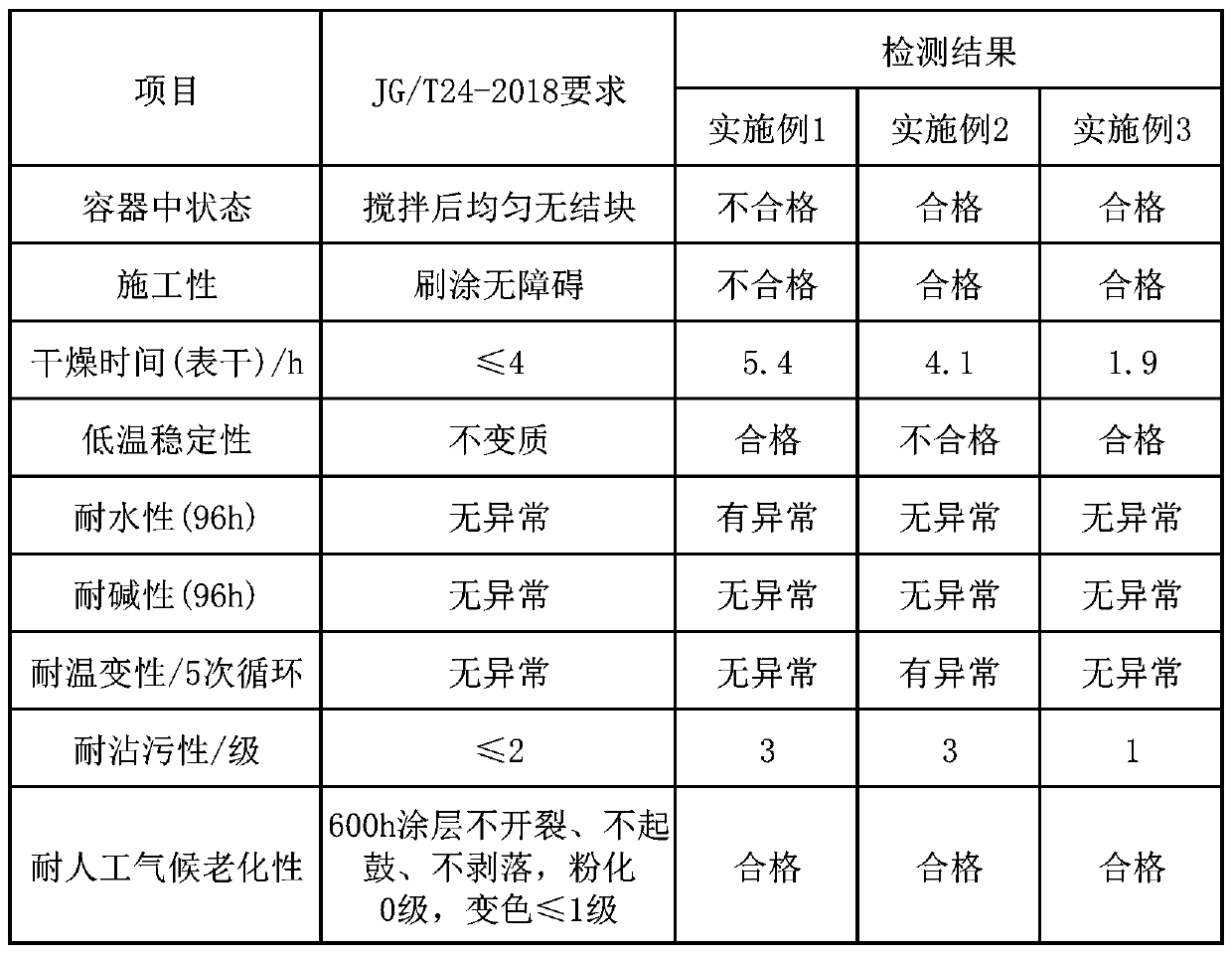

Embodiment 1

[0023] The invention provides a real stone paint

[0024] The real stone paint is mainly made of the following raw materials in parts by weight: 2495 parts of tap water, 1890 parts of real stone paint emulsion, 1468 parts of natural colored sand, 120 parts of alcohol ester twelve, 65 parts of hydroxyethyl cellulose (100,000 viscosity), 33 parts of defoamer, 10 parts of preservative, 13 parts of multifunctional additive (AMP-95).

Embodiment 2

[0026] The invention provides a real stone paint

[0027] The real stone paint is mainly made of the following raw materials in parts by weight: 2687 parts of tap water, 2150 parts of real stone paint emulsion, 1750 parts of natural colored sand, 105 parts of alcohol ester twelve, 55 parts of hydroxyethyl cellulose (100,000 viscosity), 25 parts of defoamer, 15 parts of preservative, 18 parts of multifunctional additive (AMP-95).

Embodiment 3

[0029] The invention provides a real stone paint

[0030] The real stone paint is mainly made of the following raw materials in parts by weight: 2992 parts of tap water, 2000 parts of real stone paint emulsion, 1600 parts of natural colored sand, 100 parts of alcohol ester twelve, 48 parts of hydroxyethyl cellulose (100,000 viscosity), 20 parts of defoamer, 20 parts of preservative, 20 parts of multifunctional additive (AMP-95).

[0031] The present invention provides a kind of preparation method of genuine stone paint, is used for preparing embodiment 1-3, and the steps are as follows:

[0032] (1) Get tap water earlier by weight and add in the blender, then alcohol ester 12, defoamer and preservative are added in the blender successively by weight and carry out stirring process, and stirring time is 1-3min, obtains a after being stirred evenly slurry;

[0033] (2) Get hydroxyethyl cellulose (100,000 viscosity) by weight and put it into a slurry, continue to stir, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com