Lignin-humic acid-based dispersing agent, preparation method and applications thereof

A humic acid and lignin technology, which is applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve the problems of increased production costs, complex preparation of raw materials and processes, and achieve cost savings, short preparation time, and improved dispersion effects and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

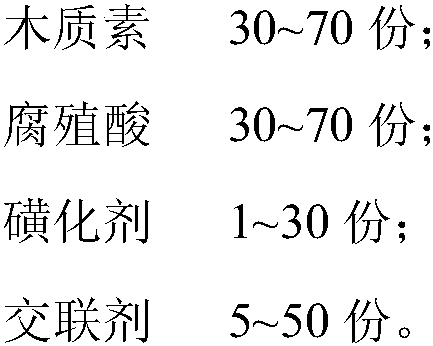

[0026] A kind of lignin-humic acid base dispersant, its preparation method comprises the steps:

[0027] Dissolving lignin and humic acid in sequence into a solution with a pH range of 9, wherein 40 parts by weight of lignin and 40 parts by weight of humic acid. The solution was heated to 80°C, 10 parts by weight of sodium sulfite was added, and reacted for 3 hours. After the reaction, formaldehyde was added dropwise, wherein the amount of formaldehyde was 10 parts by weight, and the dropping time was 1 hour. After the dropwise addition, keep the temperature constant, and continue to react for 2 h;

[0028] Use sample A to do the pulping test, the pulping steps are as follows:

[0029] (1) Crush the lump coal of the test coal sample to about 2cm, place it in a blast drying oven and dry it at 110°C for 4 hours;

[0030] (2) Weigh a certain amount of dried lump coal in a coal mill, grind for a certain period of time, and adjust the coal powder particle size distribution throug...

Embodiment 2

[0035] A kind of lignin-humic acid base dispersant, its preparation method comprises the steps:

[0036] The lignin and humic acid are sequentially dissolved into a solution with a pH range of 10, wherein 40 parts by weight of lignin and 40 parts by weight of humic acid. The solution was heated to 90°C, 10 parts by weight of sulfamic acid was added, and reacted for 3 hours. After the reaction, acrylamide was added dropwise, wherein the amount of acrylamide was 10 parts by weight, and the dropping time was 1 hour. After the dropwise addition, keep the temperature constant, and continue to react for 2 h;

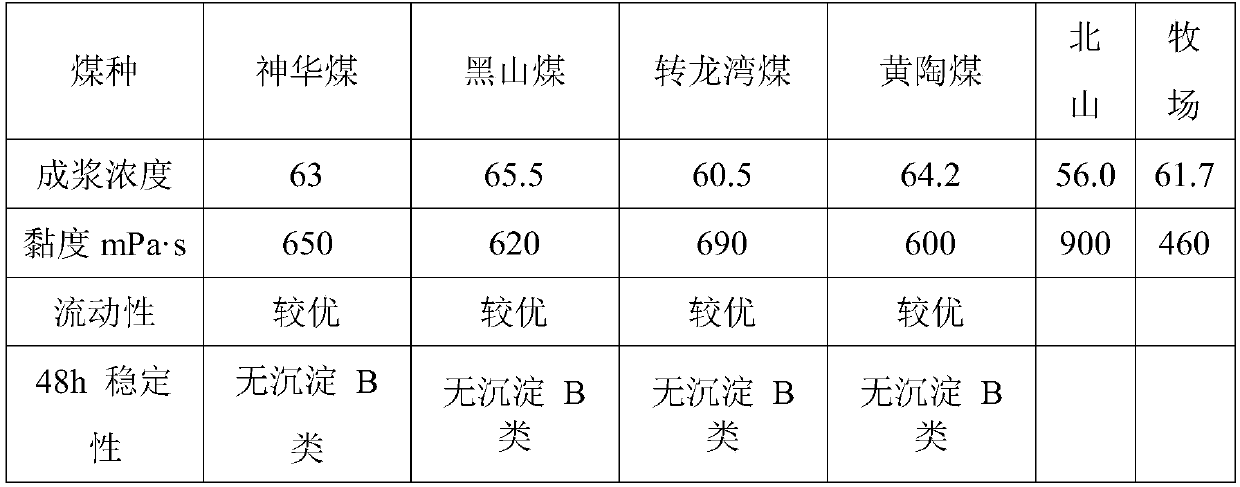

[0037] The pulping test was done with sample B, and the results are shown in Table 2.

[0038] Table 2

[0039]

Embodiment 3

[0041] A kind of lignin-humic acid base dispersant, its preparation method comprises the steps:

[0042] Dissolve lignin and humic acid sequentially into a solution with a pH range of 10, including NaOH, KOH, Ca(OH) 2 Solution, wherein lignin 40 weight parts, humic acid 40 weight parts. The solution was heated to 90°C, 10 parts by weight of chlorosulfonic acid was added, and reacted for 3 hours. After the reaction, glyoxal was added dropwise, wherein the dosage of glyoxal was 10 parts by weight, and the dropping time was 1 hour. After the dropwise addition, keep the temperature constant, and continue to react for 2 h;

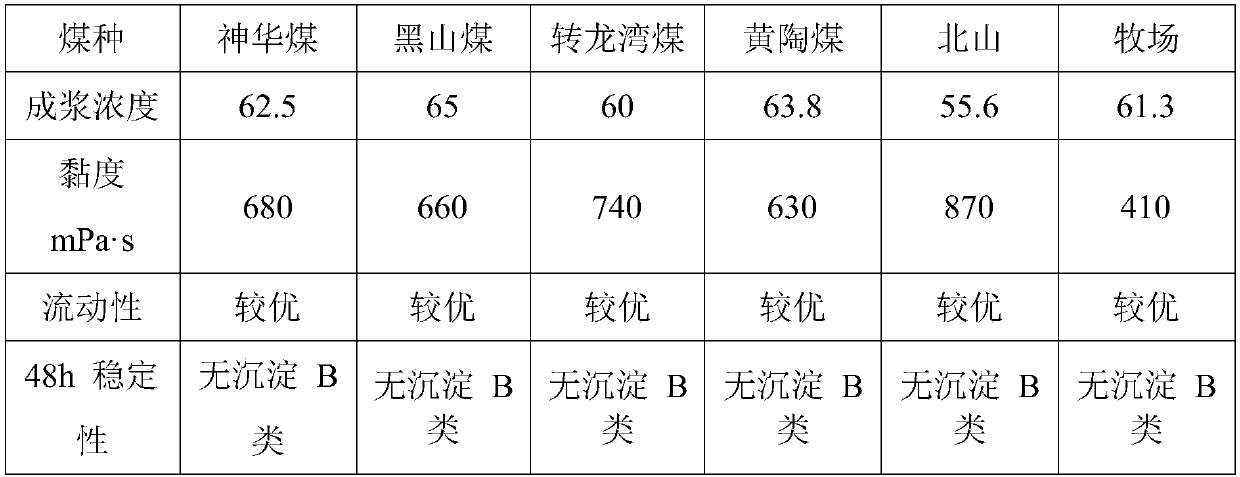

[0043] Sample C was used for pulping test, and the results are shown in Table 3.

[0044] table 3

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com