Current transformer and manufacturing method thereof

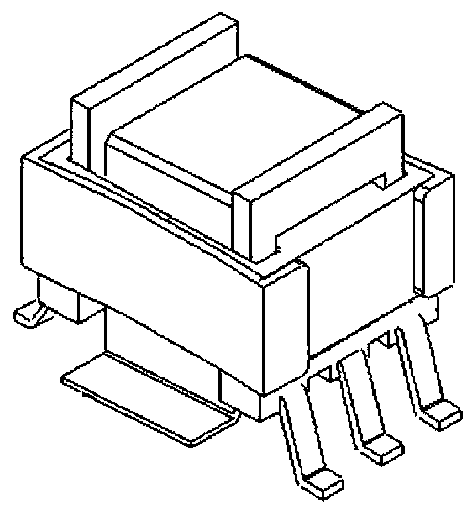

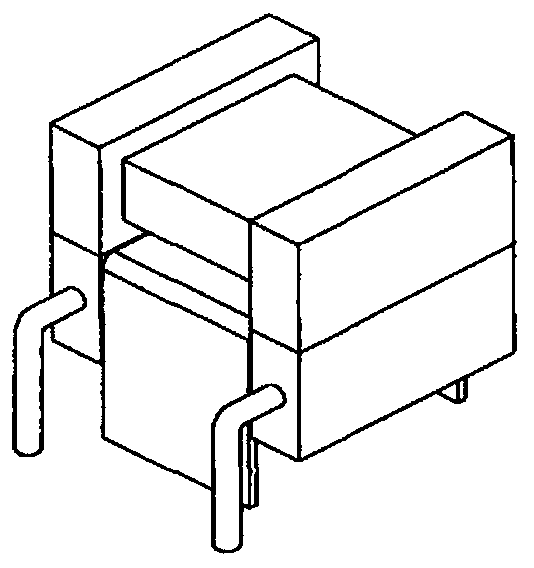

A technology for current transformers and magnetic cores, which is applied in the manufacture of inductors/transformers/magnets, inductors, transformers/inductor cores, etc., which can solve the cumbersome production process of current transformers, inconvenient automatic patch adsorption, and coplanarity Quality problems and other problems, to achieve good electromagnetic shielding effect, avoid coplanarity problems, reduce the effect of magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] The cause of the present invention, terms used, and inventive concept are briefly described first.

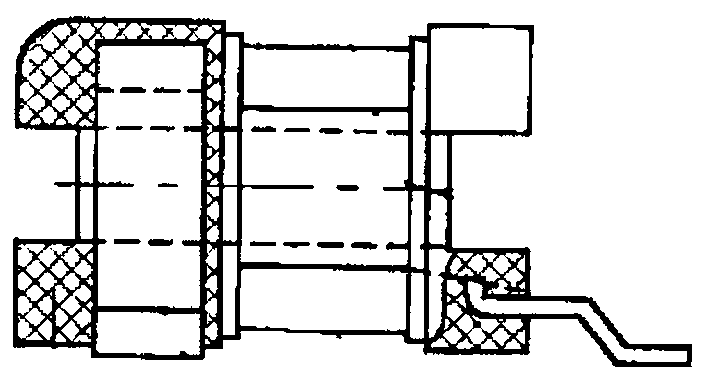

[0088] Currently commonly used current transformers, no matter whether they use the skeleton or the magnetic core as the carrier of the secondary multi-winding, or the primary metal guide piece embedded or added, are inseparable from the enameled wire winding process.

[0089] PCB (Printed Circuit Board) printed board refers to a circuit board (hereinafter referred to as PCB board) that is used in electronic and electrical products to carry out copper-clad wiring on an insulating medium to realize electrical connections between electronic devices. Since IBM took the lead in developing high-density multilayer boards (SLC) in 1991, some well-known large companies in the industry have also successively developed various high-density interconnection (HDI) microporous boards. The rapid progress of these processing technologies has prompted the design of PCBs to gradually deve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com