Polyvinyl alcohol-based carbon aerogel using waste leather as carbon source, and preparation method thereof

A polyvinyl alcohol and carbon aerogel technology, which is used in the preparation/purification of carbon, can solve the problems of environmental pollution, difficult recycling, and complex components, and achieves a unique layered structure, excellent electromagnetic shielding effect, and excellent electrical conductivity. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

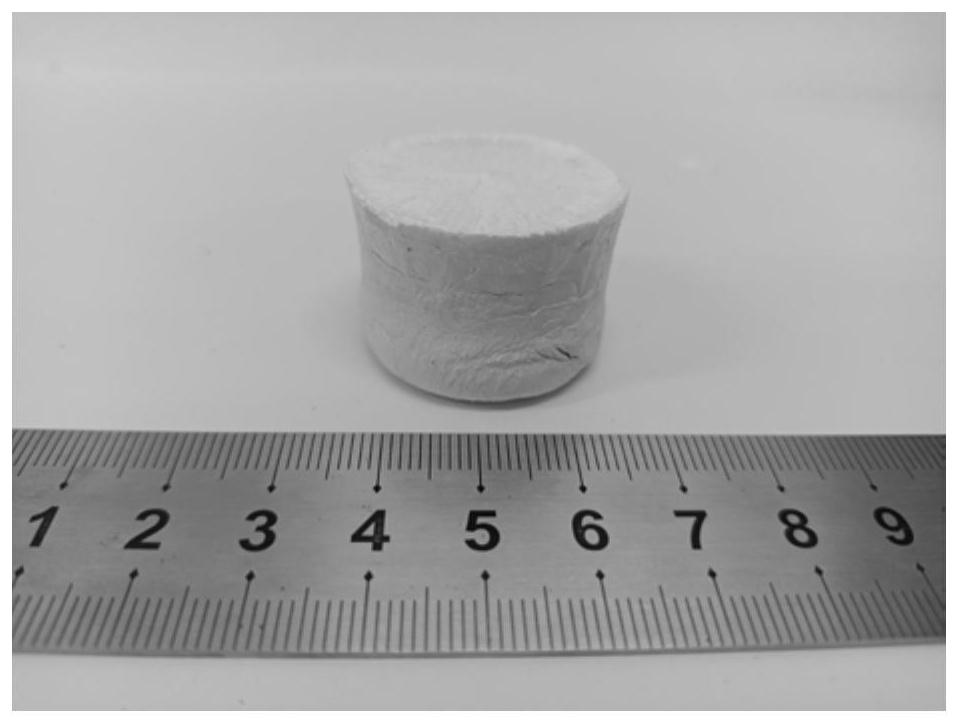

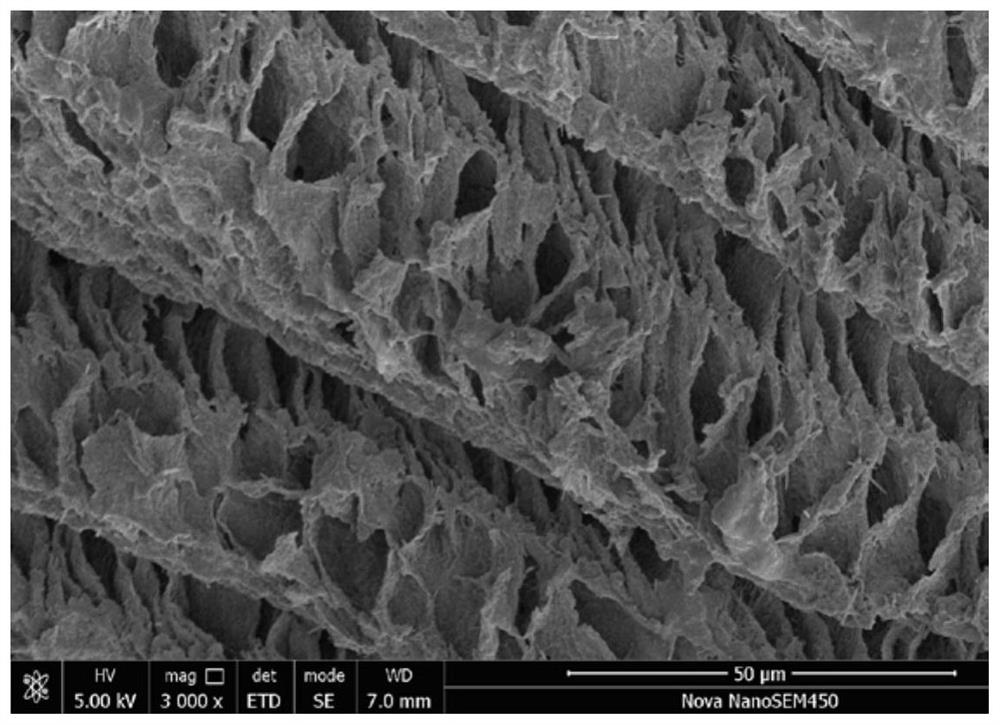

[0047] In this embodiment, a method for preparing PVA-based carbon airgel using waste leather as a carbon source, in parts by weight, comprises the following steps:

[0048] (1) Select waste chrome-tanned leather material products or scraps, and after pretreatment including washing, process and pulverize them to waste leather powder with an average particle size not higher than 4mm;

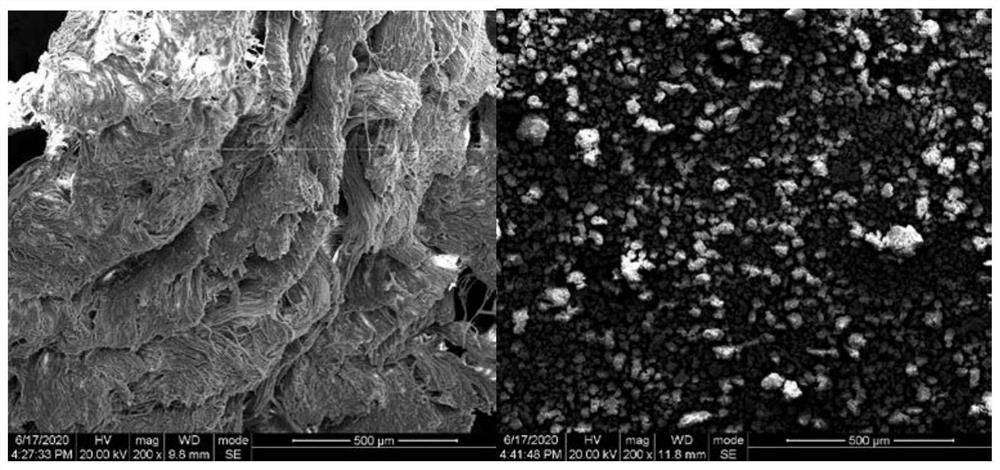

[0049] (2) Add the waste leather powder obtained in step (1) into a millstone-type solid-phase force chemical reactor for grinding and pulverization. After the milling is completed, the waste leather ultra-fine powder is collected; The process parameters of the chemical reactor are as follows: the grinding pressure is 4MPa, the temperature of the disc surface is controlled by feeding a constant temperature circulating liquid medium with a temperature of -10°C, 50 cycles of grinding, and the rotational speed of the disc is 50 rpm;

[0050] (3) 1.5 parts of discarded leather ultrafine powders are a...

Embodiment 2

[0055] In this embodiment, a method for preparing PVA-based carbon airgel using waste leather as a carbon source, in parts by weight, comprises the following steps:

[0056] (1) Select waste chrome-tanned leather material products or scraps, and after pretreatment including washing, process them into waste leather fragments with a diameter of no more than 1 to 5 cm;

[0057] (2) Put the discarded leather fragments obtained in step (1) into a millstone-type solid-phase force chemical reactor for grinding and pulverization. After the milling is completed, the waste leather ultrafine powder is collected; The process parameters of the chemical reactor are as follows: the grinding pressure is 6MPa, the temperature of the grinding disc surface is controlled by feeding a constant temperature circulating liquid medium at a temperature of -10°C, 60 cycles of grinding, and the grinding disc rotation speed is 50 rpm;

[0058](3) 1.5 parts of discarded leather ultrafine powders are added ...

Embodiment 3

[0063] In this embodiment, a method for preparing PVA-based carbon airgel using waste leather as a carbon source, in parts by weight, comprises the following steps:

[0064] (1) Select waste chrome-tanned leather material products or scraps, and after pretreatment including washing, process and pulverize them to waste leather powder with an average particle size not higher than 4mm;

[0065] (2) Add the waste leather powder obtained in step (1) into a millstone-type solid-phase force chemical reactor for grinding and pulverization. After the milling is completed, the waste leather ultra-fine powder is collected; The process parameters of the chemical reactor are as follows: the grinding pressure is 2MPa, the temperature of the grinding disc surface is controlled by feeding a constant temperature circulating liquid medium with a temperature of 10°C, 40 cycles of grinding, and the grinding disc rotation speed is 40 rpm;

[0066] (3) Add 3 parts of waste leather ultrafine powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com