All-solid-state battery with low interface impedance and high interface compatibility

An all-solid-state battery and compatibility technology, applied in the field of lithium-ion batteries, can solve the problems of reducing interface impedance and the inability to apply high-melting point solid electrolytes, etc., to achieve the effect of reducing electrochemical impedance and improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

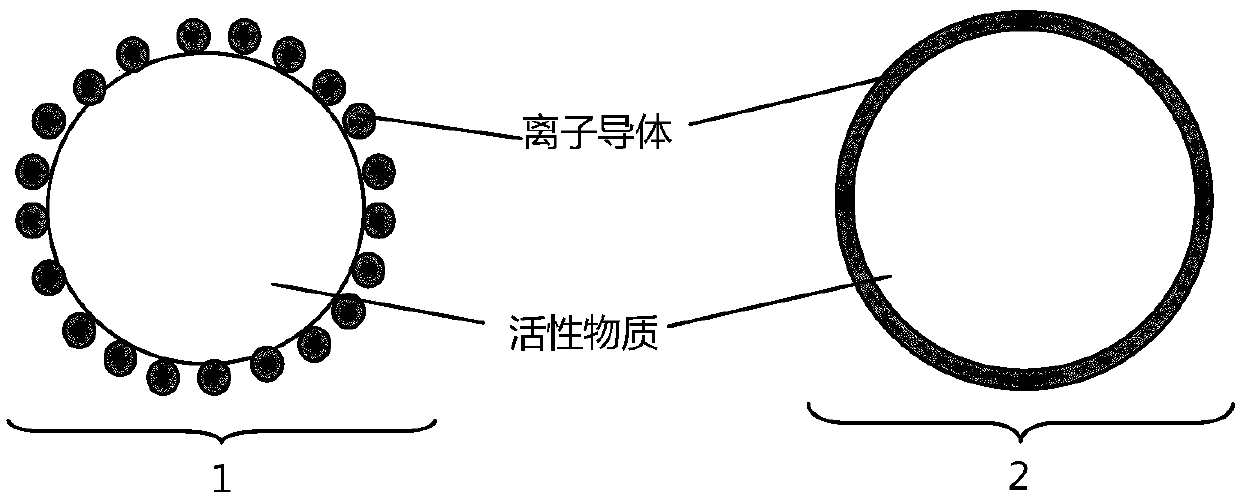

[0047] figure 1 It is a schematic diagram of the present invention coated fast ion conductor positive and negative electrode composite materials, 1 is an intermittent coating composite material, and 2 is a continuous coating composite material.

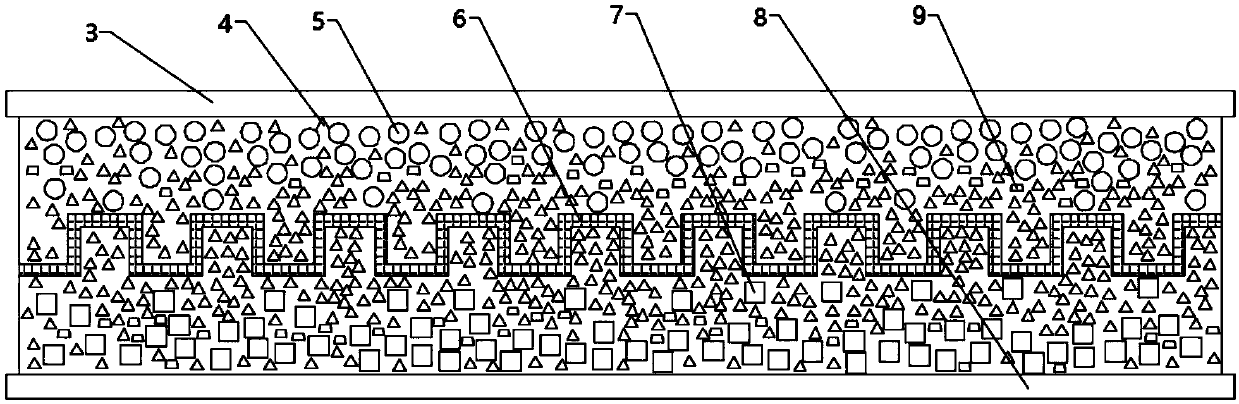

[0048] figure 2 It is a schematic diagram of the structure of the all-solid-state battery of the present invention. In the figure, 3 is a positive electrode current collector, 4 is a solid electrolyte, 5 is a positive electrode active material, 6 is a low-melting organic polymer solid electrolyte, 7 is a negative electrode active material, and 8 is a negative electrode current collector. 9 is a fast ion conductor.

[0049] Composite positive electrode preparation: choose LiNi coated with 2wt% LLZO 0.6 co 0.2 mn 0.2 o 2 (NCM622-LLZO) is the positive active material, LLZO is the solid electrolyte, PVDF is the positive binder, Super P is the positive conductor, Li 2 Zr 3 as a fast ion conductor. Among them, (NCM622-LLZO+LLZO): ...

Embodiment 2

[0059] Composite cathode preparation: xLi coated with 5wt% LATP 2 MnO 3 ·(1-x)LiMO 2 The active material (LMO-LATP) is the positive electrode active material, LATP is the solid electrolyte, PVDF is the positive electrode binder, Super P positive electrode conductor, and LiTFSI is the fast ion conductor. Among them, (LMO-LATP+LATP): PVDF: Super P: LiTFSI = 94: 2.5: 2.5: 1, after the slurry is mixed, it is prepared into a composite positive electrode sheet, and the composite positive electrode sheet is coated on both sides;

[0060] Among them, the ratio of LMO-LATP to LATP is set to five gradients of I, II, III, IV, and V, and the specific ratios are as follows:

[0061] Numbering LMO-LATPwt% LATPwt% Ⅰ 95 5 Ⅱ 90 10 Ⅲ 80 20 Ⅳ 60 40 Ⅴ 0 100

[0062] First, the active material numbered Ⅰ is coated on the current collector with a coating thickness of 30 μm, and then the numbered Ⅱ, Ⅲ, Ⅳ, and Ⅴ active material layers are coated in s...

Embodiment 3

[0069] Composite cathode preparation: LiNi coated with 3wt% LLTO 1.5 mn 0.5 o 4 (LNMO-LLTO) The positive electrode active material is the positive electrode active material, LLTO is the solid electrolyte, PVDF is the positive electrode binder, Super P positive electrode conductive agent, LiPF 6 as a fast ion conductor. Among them, (LNMO-LLTO+LLTO): PVDF: Super P: LiPF 6 =94:2:2:2, after mixing the slurry, prepare a composite positive electrode sheet, and the composite positive electrode sheet is coated on both sides;

[0070] Among them, the ratio of LMO-LATP to LATP is set to four gradients of I, II, III, and IV, and the specific ratios are as follows:

[0071] Numbering LNMO-LLTOwt% LLTOwt% Ⅰ 92 8 Ⅱ 85 15 Ⅲ 65 35 Ⅳ 0 100

[0072] First, the active material numbered Ⅰ is coated on the current collector with a coating thickness of 40 μm, and then the numbered Ⅱ, Ⅲ, Ⅳ, and Ⅴ active material layers are coated in sequence, with a thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com