Preparation method and applications of carburized titanium dioxide nanotube array

A technology of nanotube array and titanium dioxide, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of unfavorable production application, high production cost, poor repeatability, etc., and achieve low cost and full Improved discharge capacity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

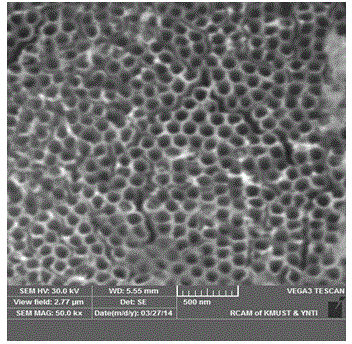

[0028] (1) Preparation of titanium dioxide nanotube arrays by anodic oxidation method: the pure Ti sheet (thickness 0.1mm) was cleaned by ultrasonic oscillation in acetone, absolute ethanol, and deionized water for 10 minutes to remove surface grease, and then the titanium sheet was chemically polished (polishing Liquid HF, HNO 3 and H 2 O volume ratio is 1:1:4), the sample is cleaned and dried in the air for later use; the Ti sheet is used as the positive electrode, and the Pt sheet is used as the counter electrode. 4 Add 0.2mol / L of H to F solution 3 PO 4 In the aqueous solution, the pH value was adjusted to 3, the oxidation voltage was 20V, and oxidized for 1 hour; the prepared sample was washed with deionized water and dried for later use.

[0029] (2) Plasma carburizing treatment to prepare carburized titanium dioxide nanotube arrays: In a double-layer glow plasma carburizing furnace, the titanium dioxide nanotube arrays prepared in step (1) were fixed on the cathode, ...

Embodiment 2

[0033] (1) Preparation of titanium dioxide nanotube arrays by anodic oxidation method: the pure Ti sheet (thickness 0.2mm) was ultrasonically cleaned in acetone, absolute ethanol, and deionized water for 30 minutes to remove surface grease, and then the titanium sheet was chemically polished (polishing Liquid HF, HNO 3 and H 2 O volume ratio is 1:1:4), the sample is cleaned and dried in the air for later use; the Ti sheet is used as the positive electrode, and the Pt sheet is used as the counter electrode. 4 In the ethylene glycol organic solution of F, the oxidation voltage was 60V, and the oxidation was performed for 3 hours; the prepared samples were washed with deionized water and dried for later use.

[0034] (2) Plasma carburizing treatment to prepare carburized titanium dioxide nanotube arrays: in a double-layer glow plasma carburizing furnace, fix the titanium dioxide nanotube arrays prepared in step (1) on the cathode, and connect the anode with methane as the carbon s...

Embodiment 3

[0037] (1) Preparation of titanium dioxide nanotube arrays by anodic oxidation method: clean the pure Ti sheet (thickness 0.1 mm) in acetone, absolute ethanol, and deionized water for 15 minutes with ultrasonic oscillation to remove surface grease, and then chemically polish the titanium sheet (polishing Liquid HF, HNO 3 and H 2 O volume ratio is 1:1:4), the sample is cleaned and dried in the air for later use; the Ti sheet is used as the positive electrode, and the Pt sheet is used as the counter electrode. 4 In the dimethyl sulfoxide organic solution of F, the oxidation voltage is 50V, and the oxidation is performed for 2 hours; the prepared sample is washed with deionized water, and dried for later use.

[0038] (2) Plasma carburizing treatment to prepare carburized titanium dioxide nanotube arrays: in a double-layer glow plasma carburizing furnace, the prepared titanium dioxide nanotube arrays were fixed on the cathode, and the carbon sheet was used as the carbon source t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com