A kind of high-nickel ternary precursor co-doped with metal vanadate compound and preparation method thereof

The technology of metal vanadate compound and precursor is applied to the field of high nickel ternary precursor co-doped with metal vanadate compound and its preparation field, which can solve the problems such as limited application of copper vanadate material, and solve the problem of cycle rate Poor performance, low electrochemical impedance, and the effect of improving the yield of the production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

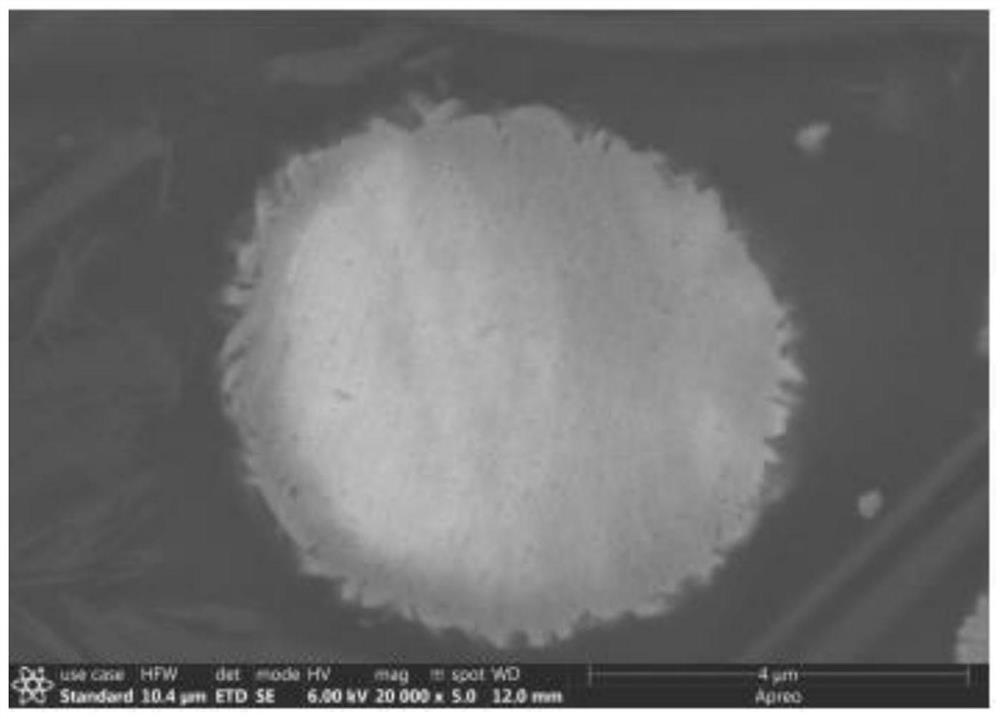

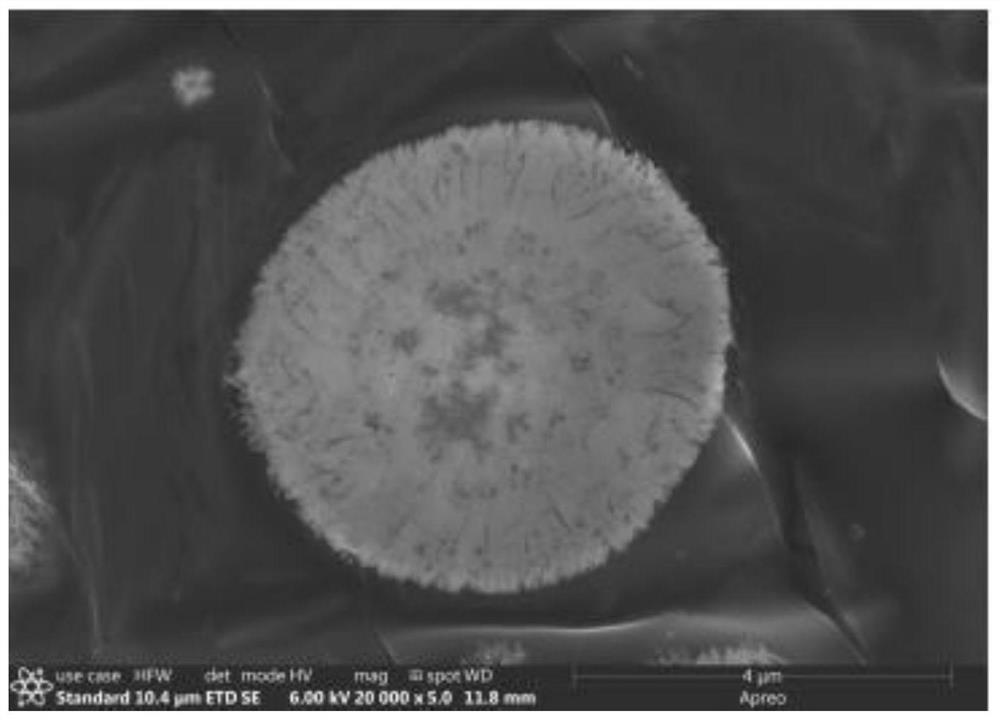

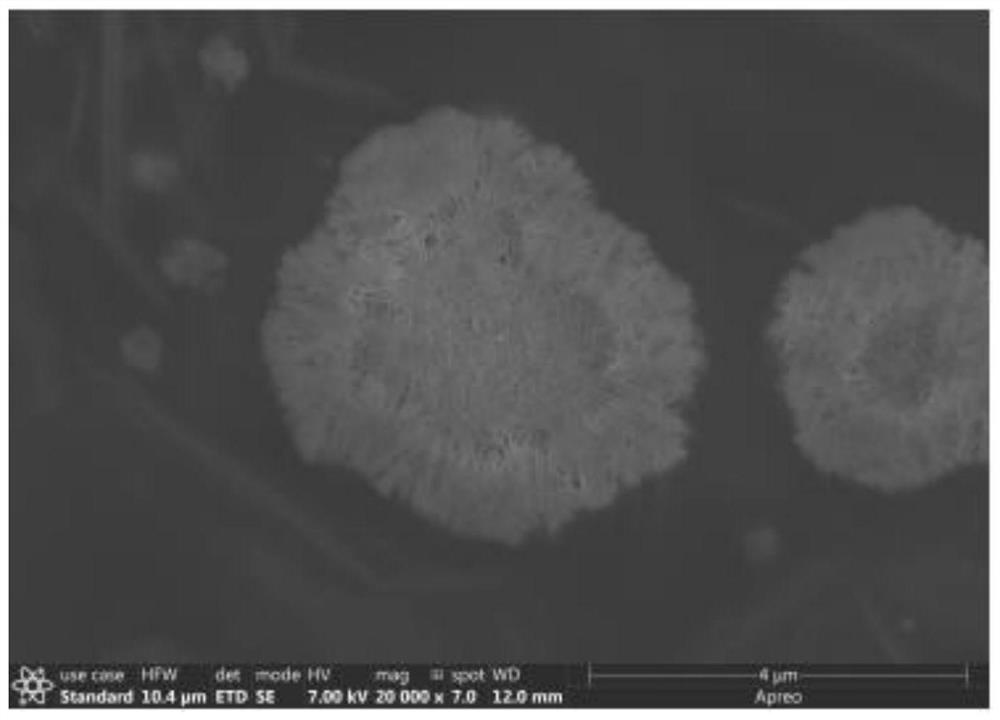

Image

Examples

Embodiment 1

[0058] This embodiment includes the following steps:

[0059] (1) Take 30 L of 25% industrial ammonia water to obtain complexing agent solution A; uniformly mix 12 kg of sodium hydroxide with hot pure water to prepare 30 L of precipitant solution B;

[0060] (2) Mix 16.462 kg nickel sulfate hexahydrate, 2.217 kg cobalt sulfate heptahydrate, 0.658 kg manganese sulfate monohydrate (nickel-cobalt-manganese molar ratio Ni:Co:Mn=8.0:1.0:1.0) with hot pure water Prepare 50L metal salt solution C;

[0061] (3) Mix 1.2193 kg of sodium metavanadate with hot pure water, mix thoroughly to obtain 10 L of vanadium salt solution D, and store it in a constant temperature water bath at a constant temperature of 35 °C until use;

[0062] (4) Mix 0.0599 kg of anhydrous lithium hydroxide with hot pure water to prepare 5 L of co-doped metal salt solution E, and keep it sealed for later use;

[0063] (5) Solutions A, B, C, and E are kept at a constant temperature of 40°C; add hot pure water to 1...

Embodiment 2

[0069] This embodiment includes the following steps:

[0070] (1) Mix 15 L of water and 9 kg of ethylenediamine evenly, and adjust the pH of the system to 10.5 with sodium hydroxide to obtain complexing agent solution A; mix 12 kg of sodium hydroxide with 30 L of deionized hot pure water Prepare precipitant solution B together;

[0071] (2) Fully mix 28.52 kg manganese nitrate hexahydrate, 3.158 kg cobalt nitrate heptahydrate, 6.072 kg manganese nitrate tetrahydrate (nickel-cobalt-manganese molar ratio Ni:Co:Mn=7.3:0.9:1.8) with deionized hot pure water After uniformity, the volume was adjusted to 60 L to obtain metal salt solution C;

[0072] (3) Mix 2.2069 kg of sodium orthovanadate with hot pure water, mix completely and set the volume to 15 L to obtain vanadium salt solution D, and store it in a constant temperature water bath at a constant temperature of 40 °C until use;

[0073] (4) Mix 0.7887 kg of magnesium sulfate heptahydrate with hot pure water to prepare 8L of co...

Embodiment 3

[0080] This embodiment includes the following steps:

[0081] (1) Mix hot pure water and 1.0 kg of ethylenediaminetetraacetic acid evenly, adjust the pH value of the solution to 11.5 with sodium hydroxide solution, and prepare 100 L complexing agent solution A; mix hot pure water with 0.92 kg Sodium hydroxide was mixed evenly to prepare 100 L of precipitant solution B;

[0082] (2) Mix 73.788 kg of nickel chloride hexahydrate, 24.628 kg of cobalt chloride hexahydrate, and 20.524 kg of manganese chloride tetrahydrate (nickel-cobalt-manganese molar ratio Ni:Co:Mn=6:2:2) with hot pure water. Mix well and prepare 200 L metal salt solution C;

[0083] (3) Dissolve 3.6400 kg of vanadium pentoxide in sodium hydroxide, mix it evenly and set the volume to 20 L to obtain vanadium salt solution D, and store it in a constant temperature water bath at a constant temperature of 45 °C until use;

[0084] (4) Mix 8.6600 kg of lanthanum nitrate hexahydrate with hot pure water to prepare 10 L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com