Preparation method of nickel manganese oxide

A technology of nickel manganese oxide and titanium hydroxide, applied in nickel compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of difficult to achieve surface coating process, poor doping and fusion effect, affecting doping effect, etc. , to avoid the mixed discharge of nickel and lithium ions, to avoid the mixed discharge of nickel and lithium, and to improve the degree of oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

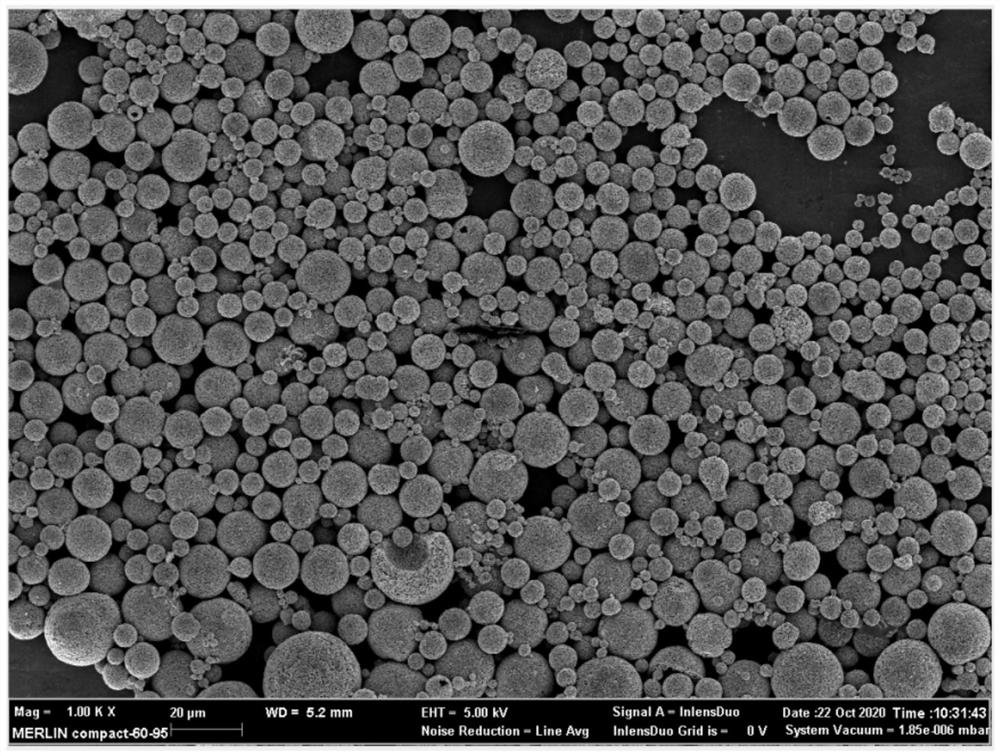

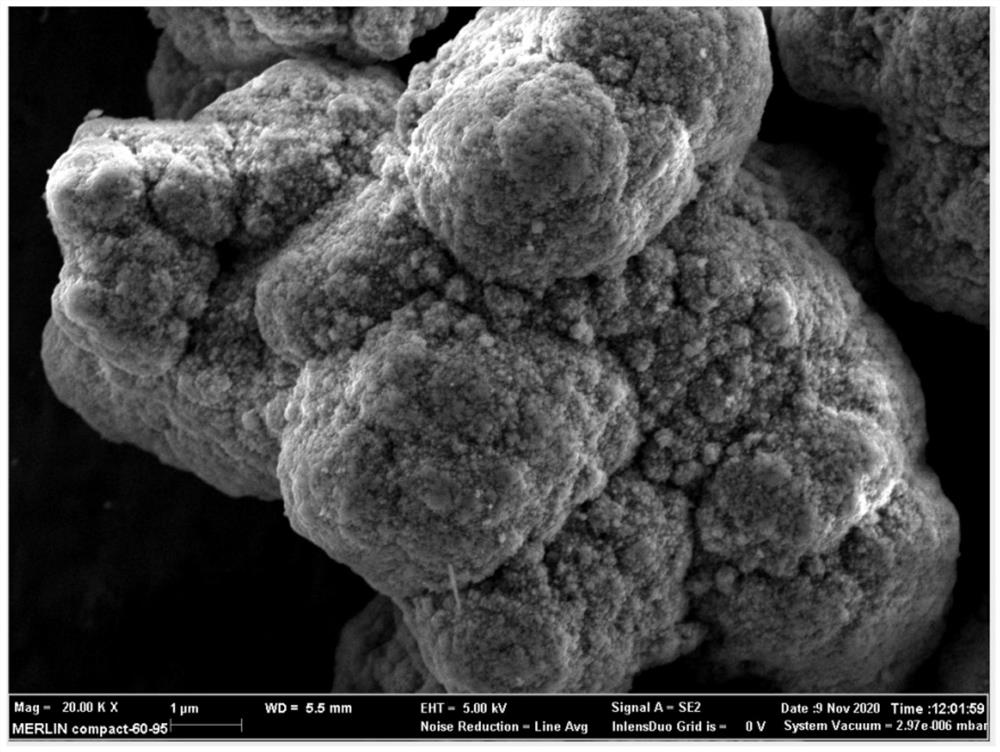

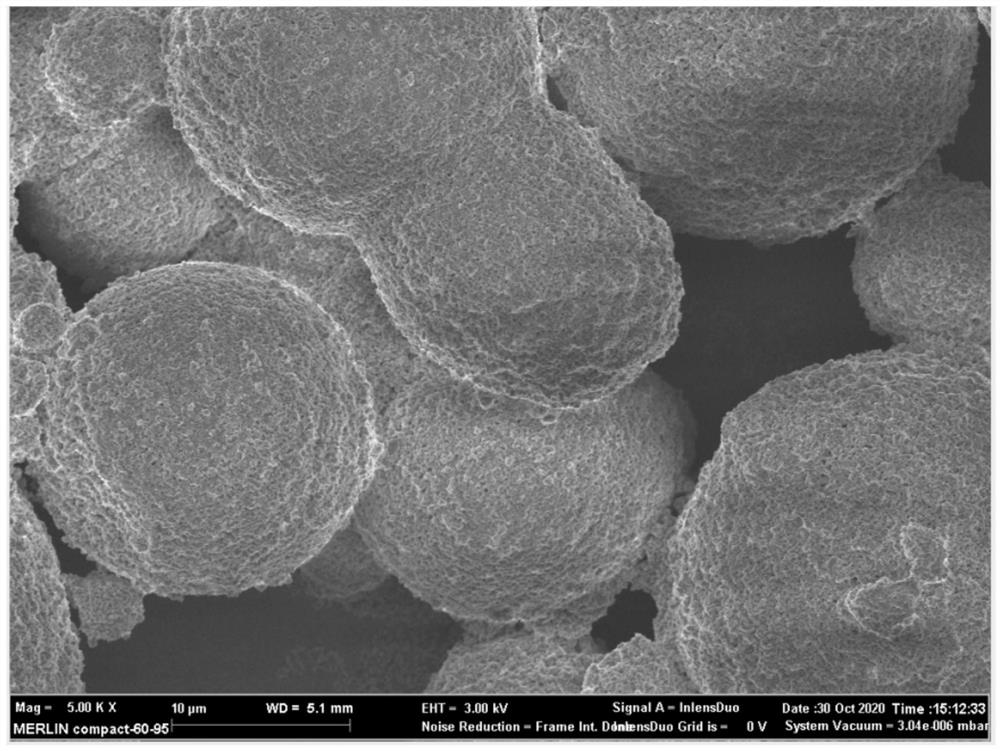

[0038] The present invention will be described below with reference to the drawings, and the method of preparing a nickel manganese oxide of the present invention is as follows:

[0039] 1) The nickel chloride solution, titanium tetrachloride is added to 8-10 mol / L of ammonia water, and the resulting precipitate obtained after stirring, the chlorinated chloride chloride chloride crystal and titanium oxide mixture;

[0040] 2) Add a mixture of chlorinated chloride chloride chloride and titanium oxide to potassium permanganate, then add pure water, stirred and dissolved, mix well to obtain a slurry, drying drying, to obtain spray drying material;

[0041]3) Put the spray drying material into the high temperature calciner, to obtain a calcined material, a total calcination time of 10-15 h, and the calcination temperature is 700-900 ° C;

[0042] 4) Add the calcination to pure water, and then passed through the ball mill ball milling, the ball milling is 5-8 μm, then discharged, aft...

Embodiment 1

[0054] A method of preparing a nickel manganese oxide, its steps are as follows:

[0055] 1) The nickel chloride solution, titanium tetrachloride is added to 9.5 mol / L of ammonia water, after stirring, the obtained precipitate is filtered after filtration, resulting in a mixture of chloride chloride chloride crystals and titanium oxide. The concentration of the nickel chloride solution is 2 mol / L, titanium tetrachloride is added to the liquid surface before the addition of a layer of protective layer, which is a titanate, and the thickness of the protective layer is 2 cm. .

[0056] When the nickel chloride solution, titanium tetrachloride is added to 9.5 mol / L of ammonia water, and the reaction temperature is 30 ° C, the reaction temperature is 30 ° C, and the reaction temperature is 30 ° C, chlorine in the sealing reaction kettle The molar ratio of nickel chloride and ammonia in the aqueous nickel is 1:30, and the stirring speed is 100R / min, and the addition is 15 min af...

Embodiment 2

[0066] A method of preparing a nickel manganese oxide, its steps are as follows:

[0067] 1) The nickel chloride solution, titanium tetrachloride is added to the ammonia water of 10 mol / L, after stirring, the obtained precipitate was washed after filtration, resulting in a mixture of chloride chloride chloride crystals and titanium oxide;

[0068] 2) Add a mixture of chlorinated chloride chloride chloride and titanium oxide to potassium permanganate, then add pure water, stirred and dissolved, mix well to obtain a slurry, drying drying, to obtain spray drying material;

[0069] 3) Put the spray drying material into the high temperature calciner, to obtain a calcined material, the calcination time is 15 h, the calcination temperature is 900 ° C;

[0070] 4) Add the calcined water to the pure water, and then passed through the ball mill ball mill, the ball milling is 5.6 μm, then discharged, after washing, the potassium ion content in the wash water is less than 100 ppm, then the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com