Corrosion inhibition treatment method for magnesium alloy in sodium chloride solution

A technology of sodium chloride solution and treatment method, which is applied in the field of corrosion inhibition treatment of magnesium alloys, can solve problems such as poor corrosion resistance and limitations, and achieve the effects of improving corrosion resistance, low cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

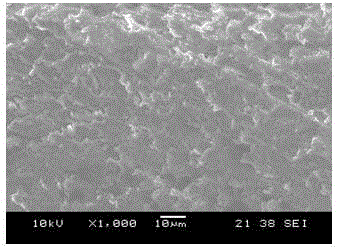

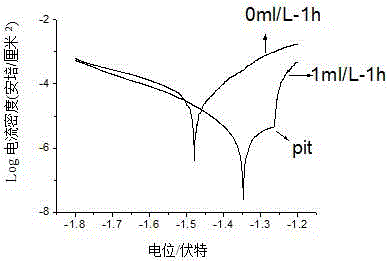

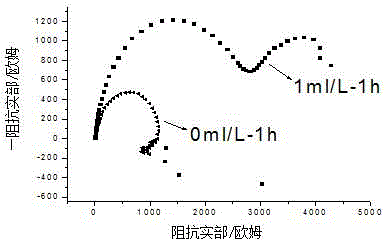

Image

Examples

Embodiment

[0014] (1) Grind the AZ91 magnesium alloy with a size of 30mm×20mm×3mm successively with 600#, 800#, 1000# water-resistant sandpaper, after washing with water, degrease in alkaline degreasing solution at 70°C for 20 minutes , and then ultrasonically cleaned in deionized water at 70°C for 15 minutes, washed with water, and dried for later use. The formula of the alkaline degreasing liquid is: sodium phosphate 40g / L, sodium silicate 15g / L, sodium carbonate 40g / L.

[0015] (2) Prepare 100 ml of an aqueous solution of triethanolamine with a concentration of 1 ml / L, and stir it magnetically for 0.5 hours at 25°C, and the solution becomes transparent.

[0016] (3) Immerse the magnesium alloy treated in step (1) in the solution obtained in step (2), take it out after soaking it for 1 hour at 25°C, wash it twice with deionized water to remove the remaining solution on the surface, and dry it to obtain a surface with The magnesium alloy of the triethanolamine adsorption layer, that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com