Fuzzy grabbing method and device based on machine vision

A machine vision, fuzzy technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problem of low fault tolerance, achieve the effect of large fault tolerance, prevent grasping failure or impact on the shell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings. Those skilled in the art should understand that the following does not constitute a limitation to the protection scope of the present invention.

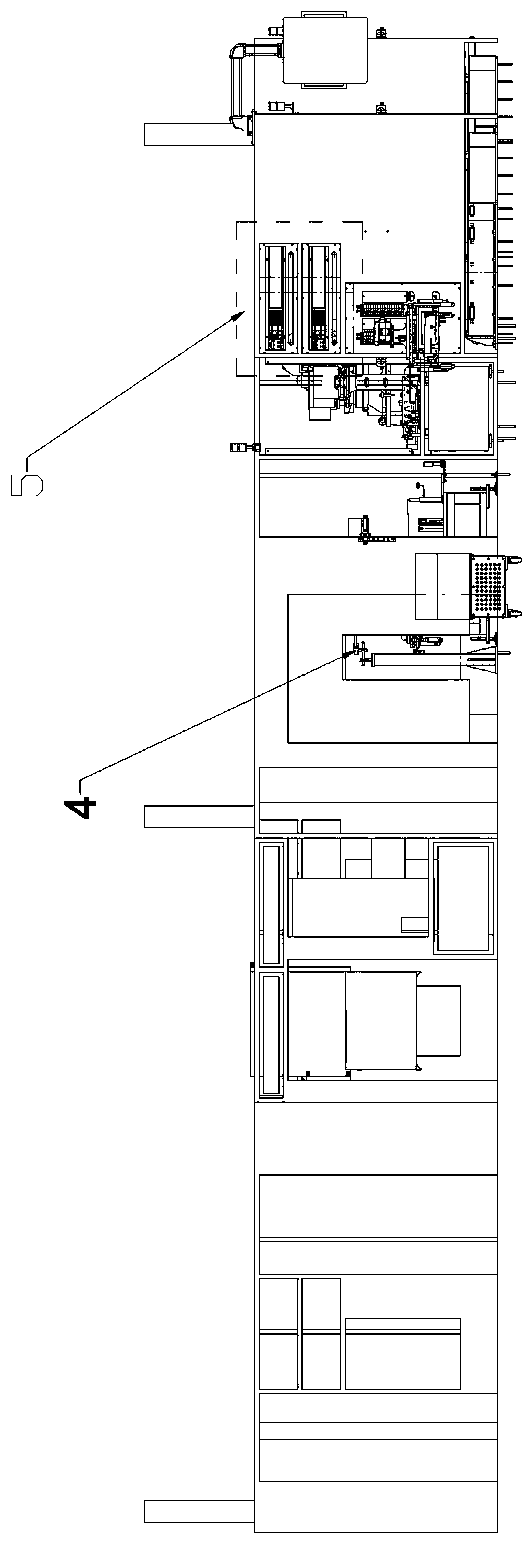

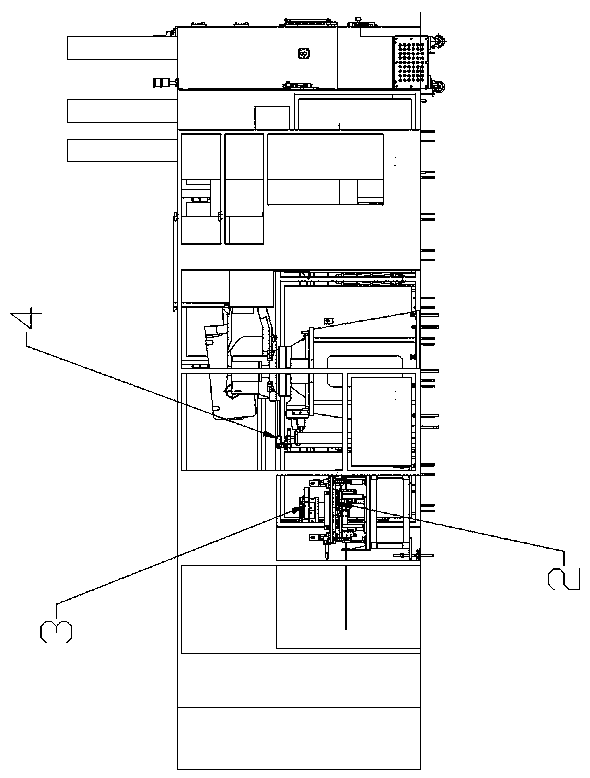

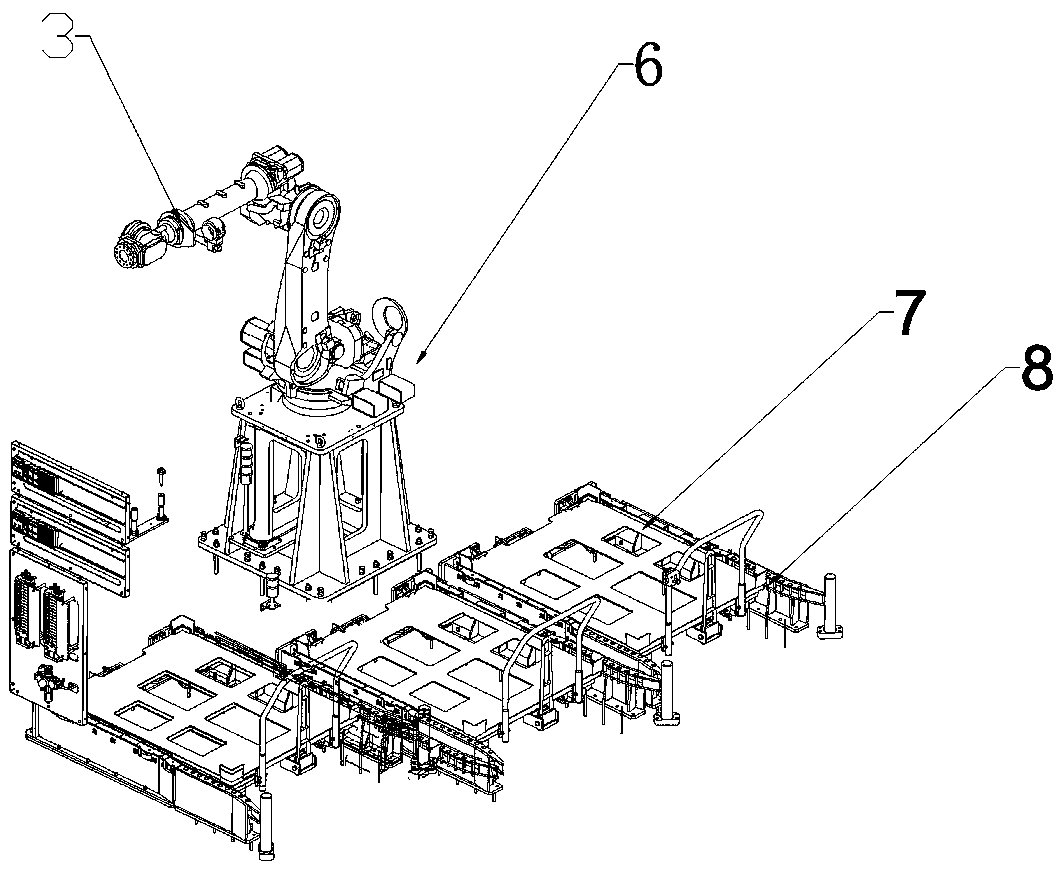

[0025] Examples such as figure 1 , figure 2 , image 3 , Figure 4 Shown, a kind of fuzzy grasping method based on machine vision, the device that realizes this fuzzy grasping method comprises:

[0026] The whole equipment is mainly composed of material buffer area 1, 3D camera 2, manipulator 3, fixed scanning gun 4, PLC control system 5, material cart 7, guide rail 8, and shell repair area 10.

[0027] Material buffer area 1 includes material buffer area 1-A, material buffer area 1-B and material buffer area 1-C, and material buffer area 1-C is an empty material area; once material buffer a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com