Purification method of high-load iohexol

A purification method, the technology of iohexol, applied in the separation/purification of carboxylic acid amide, organic chemistry, etc., can solve the problems such as greater influence on the yield and purity of iohexol, small adsorption amount of iohexol, unfavorable industrial scale-up, etc. , to achieve mild operating conditions, reduce production costs, and prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

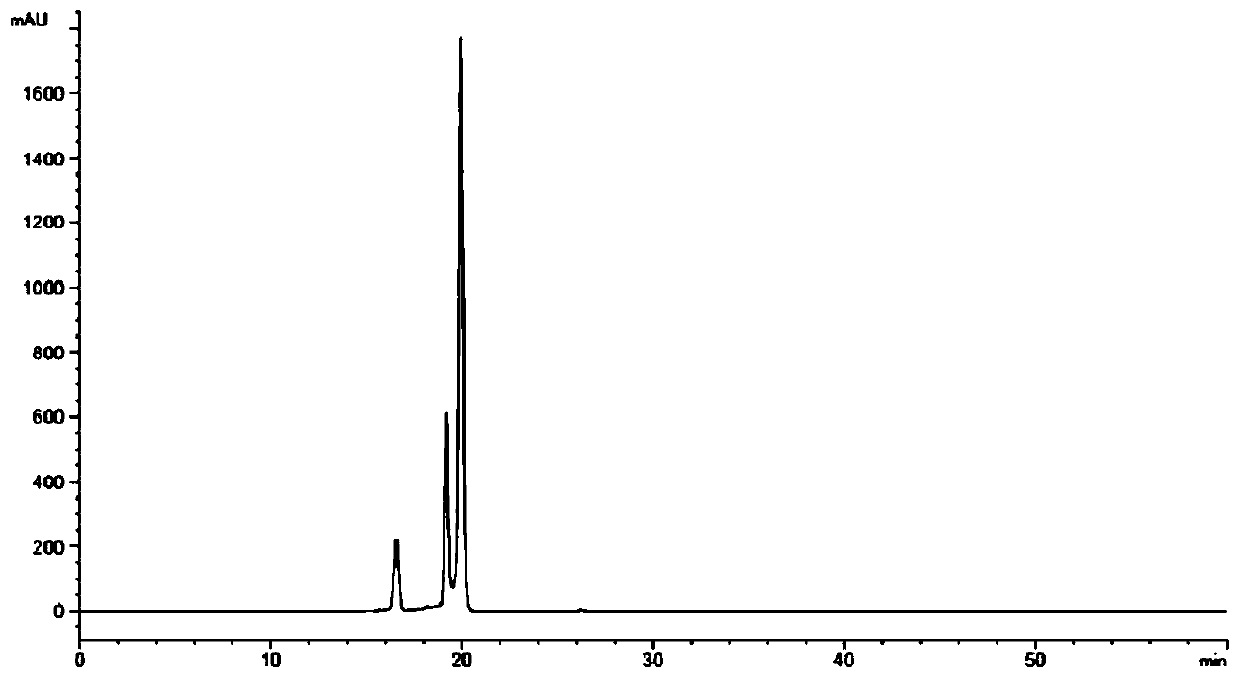

[0043] In a chromatographic column of 16×180 mm, 36 ml of ultra-high cross-linked macroporous styrene / divinylbenzene copolymer microspheres (LX-161 produced by Xi’an Lanxiao Technology New Materials Co., Ltd., with a resin particle size range of 50-150μm, the pore size is The specific surface area is 1000m 2 / g) as a chromatographic filler. Weigh 7g iohexol crude product in a beaker (the liquid chromatogram is as follows figure 1 As shown, 0.192g iohexol crude product was loaded per milliliter of resin), stirred and dissolved with 25ml deionized water, then filtered with a 0.45 μm filter membrane, and the filtrate was collected for use.

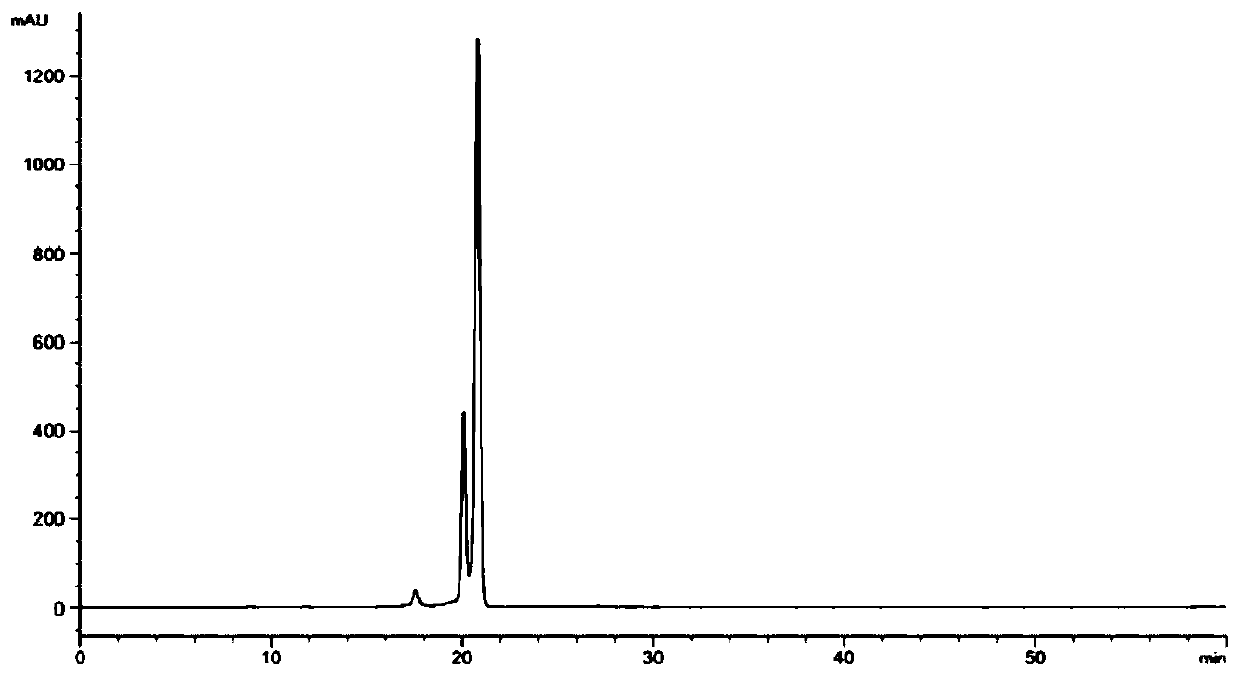

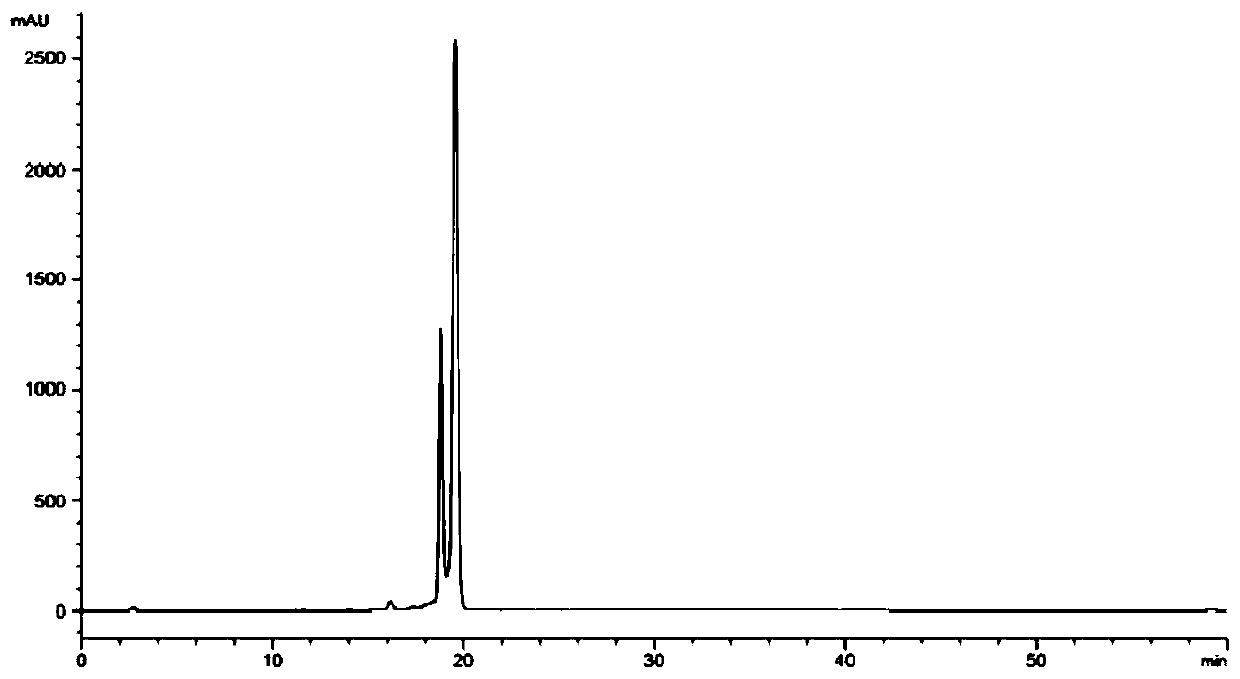

[0044] Control the flow rate to 3ml / min (0.83 column volume 10 / min), first equilibrate the chromatography column with deionized water for 6 column volumes. Then the filtered iohexol crude product solution is loaded into the chromatographic column, and 14 column volumes are used to elute with deionized water and the effluent (iohexol main ...

Embodiment 2

[0046] In a chromatographic column of 10 × 600 mm, 47 ml of ultra-high cross-linked macroporous styrene / divinylbenzene copolymer microspheres (LX-361 produced by Xi'an Lanxiao Technology New Materials Co., Ltd., with a resin particle size range of 75-120μm, the pore size is The specific surface area is 1100m 2 / g) as a chromatographic filler. Take by weighing 10g iohexol crude product in beaker (liquid phase chromatogram is as follows figure 1 As shown, 0.212g iohexol crude product was loaded per milliliter of resin), stirred and dissolved with 30ml deionized water, then filtered with a 0.45 μm filter membrane, and the filtrate was collected for use.

[0047] Control the flow rate to 4ml / min (0.85 column volume 10 / min), and first equilibrate the chromatography column with deionized water for 6 column volumes. Then the filtered iohexol crude product solution is loaded into the chromatographic column, and 16 column volumes are eluted with deionized water and the effluent (io...

Embodiment 3

[0049]In a chromatographic column of 35 × 600 mm, 576 ml of ultra-high cross-linked macroporous styrene / divinylbenzene copolymer microspheres (LX-22 produced by Xi'an Lanxiao Technology New Materials Co., Ltd., with a resin particle size range of 50-100μm, the pore size is The specific surface area is 1100m 2 / g) as a chromatographic filler. Take by weighing 150g iohexol crude product in beaker (liquid phase chromatogram is as follows figure 1 As shown, 0.260g iohexol crude product is loaded per milliliter of resin), stirred and dissolved with 500ml pure water, then filtered with a 0.45 μm filter membrane, and the filtrate is collected for use.

[0050] Control the flow rate to 5ml / min (0.87 column volume 10 / min), and first equilibrate the chromatography column with depurified water for 7 column volumes. Then the filtered iohexol crude product solution is loaded into the chromatographic column, and 17 column volumes are eluted with pure water and the effluent (main peak o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com