Mildew-proof environment-friendly water-based color paste suitable for color mixing of automatic color mixer and preparation method of mildew-proof environment-friendly water-based color paste

A water-based colorant and colorant technology, applied in antifouling/underwater coatings, pigment slurries, and biocide-containing paints, etc., which can solve problems such as hazards, restrictions on the use of anti-mold fungicides, and high skin irritation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

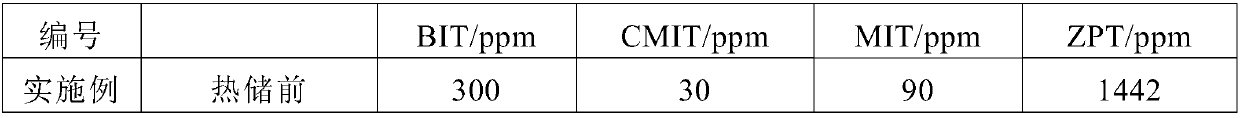

Examples

preparation example Construction

[0065] The preparation method of mildew-proof type environment-friendly color paste of the present invention comprises steps:

[0066] (1) Add water, wetting agent, dispersant, anti-mold and fungicide composition, co-solvent, pH regulator and defoamer into the dispersion tank, and disperse at 500-1200r / min for 15-20min to obtain a mixed Liquid I;

[0067] (2) Mix the mixed solution I with the pigment and stir at 300-400r / min to obtain the mixed solution II;

[0068] (3) Mix the mixed solution II with a thickener, add water to adjust the viscosity, and defoam to obtain the color paste.

[0069] In another preferred example, in step (2), the filler is also added.

[0070] In another preference, the step (3) also includes the steps before:

[0071] (3-1) Disperse the mixture II at a speed of 800-1200r / min for 20min-2h (preferably 30min-1.5h) to form mixture III;

[0072] (3-2) Grinding mixture III to obtain mixture IV, and then subjecting mixture IV to step (3).

[0073] In ...

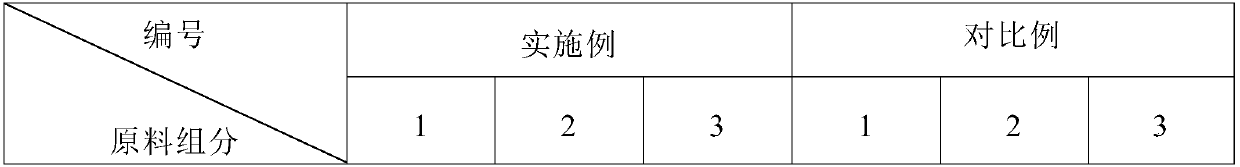

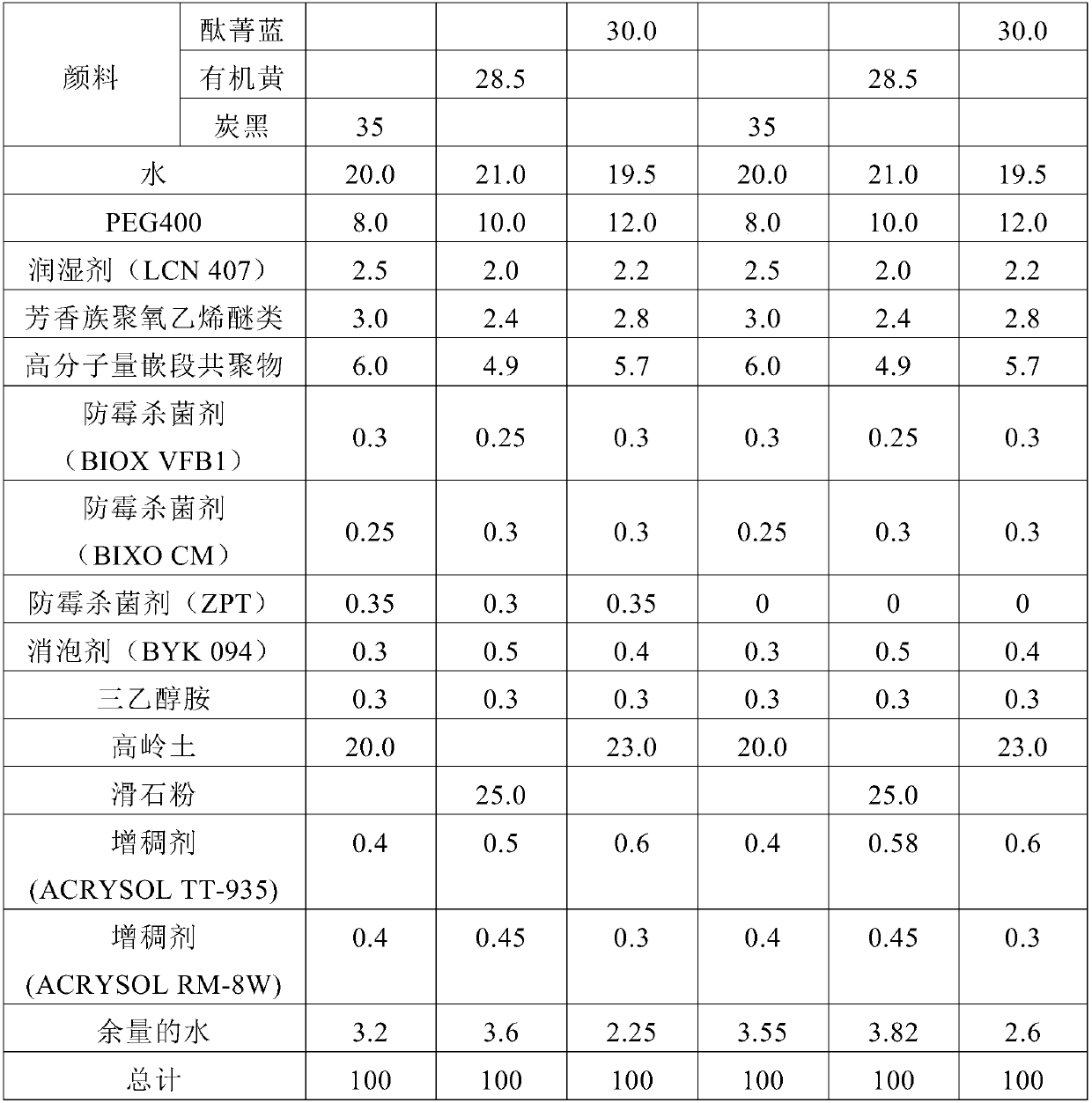

Embodiment 1-3

[0134](1) Reserve 10% of water, add 90% of water, wetting agent, dispersant, anti-mildew fungicide and co-solvent PEG400 and other materials except pigment, kaolin, talcum powder and thickener to the dispersion tank in order In the process, disperse at a speed of 500-1200r / min for 15-20min to obtain the mixed solution I;

[0135] (2) Adjust the rotation speed to 300-400r / min, add the pigment and filler into the mixed solution 1, and stir fully to obtain the mixed solution II;

[0136] (3) Disperse the mixture II at a speed of 800-1200r / min at a high speed for not less than 20 minutes, and add 10% of the water reserved in step (1) during the dispersion process to obtain mixture III;

[0137] (4) Grinding the mixture III horizontally, the grinding medium is 0.4-0.8mm zirconia beads or ceramic beads, and grinding continuously for 30min to obtain the mixture IV;

[0138] (5) The mixture IV is weighed, and then the thickener and the remaining water are added according to the propo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com