Foaming agent, tundish covering agent, and preparation method and application thereof

A foaming agent and tundish technology, applied in electric furnaces, furnaces, furnace types, etc., can solve problems such as inability to make better use of plasma heating, difficulty in adapting to the plasma heating process, and reduced plasma heating efficiency, so as to reduce dust and plasma Arc flickering, not easy to absorb water, good preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] According to one aspect of the present invention, a preparation method of the above foaming agent, the preparation method comprises the following steps:

[0063] The raw materials are mixed uniformly to obtain a foaming agent.

[0064] The present invention provides the preparation method of the above foaming agent, the preparation method is to mix the raw materials uniformly to obtain the foaming agent. The above preparation method has the advantage of simple preparation process.

[0065] According to one aspect of the present invention, a tundish covering agent comprising the above blowing agent is provided.

[0066] In the tundish covering agent provided by the present invention, the tundish covering agent comprises the above foaming agent, the tundish covering agent has foaming ability, can form foamed slag during the tundish plasma heating process, and can further adapt to the tundish plasma heating process, better play the role of plasma heating.

[0067] In a ...

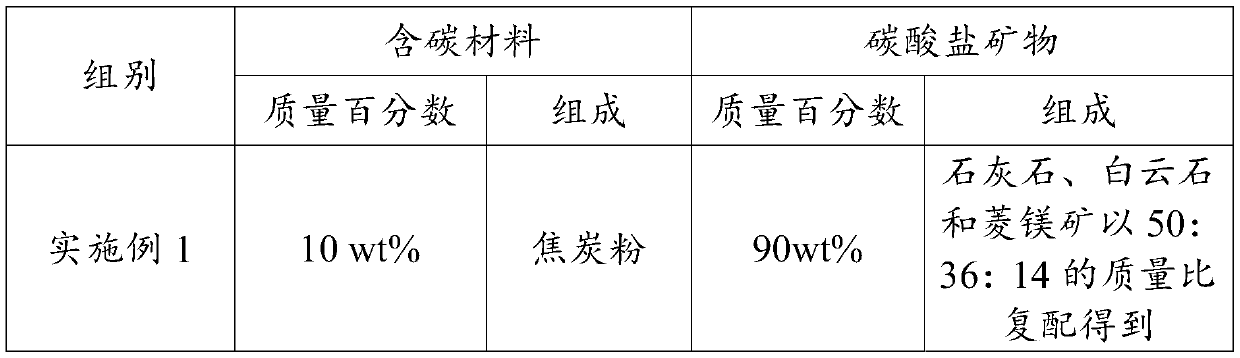

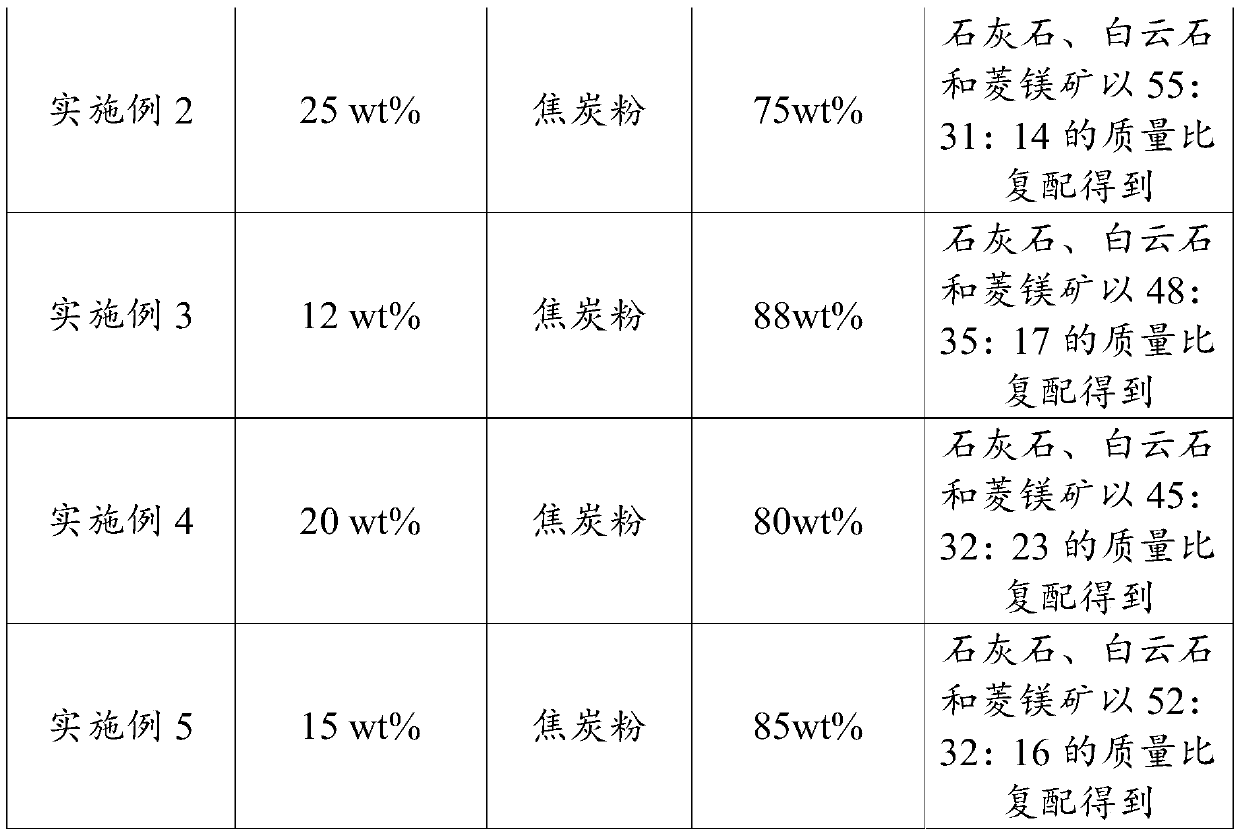

Embodiment 1~5

[0086] A foaming agent, in mass percent, the foaming agent comprises the following components:

[0087]

[0088]

[0089] Note: the particle size of the limestone is 200-250 mesh; the particle size of the dolomite is 150-200 mesh; the particle size of the magnesite is 180-220 mesh; the particle size of the carbonaceous material is 180-220 mesh .

[0090] The preparation method of the foaming agent comprises the following steps: mixing the raw materials uniformly to obtain the foaming agent.

Embodiment 6

[0092] A tundish covering agent, by mass percentage, the foaming agent comprises the following components: the foaming agent 5% prepared in Example 1, CaO and SiO 2 The mixture of 65%, Al 2 O 3 23%, MgO 3% and Fe 2 O 3 4%;

[0093] The above CaO and SiO 2 A mixture of CaO and SiO 2 The mass ratio of 1.8;

[0094] The preparation method of the above-mentioned tundish covering agent comprises the following steps: mixing the raw materials to obtain a tundish covering agent with a water content of 0.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com