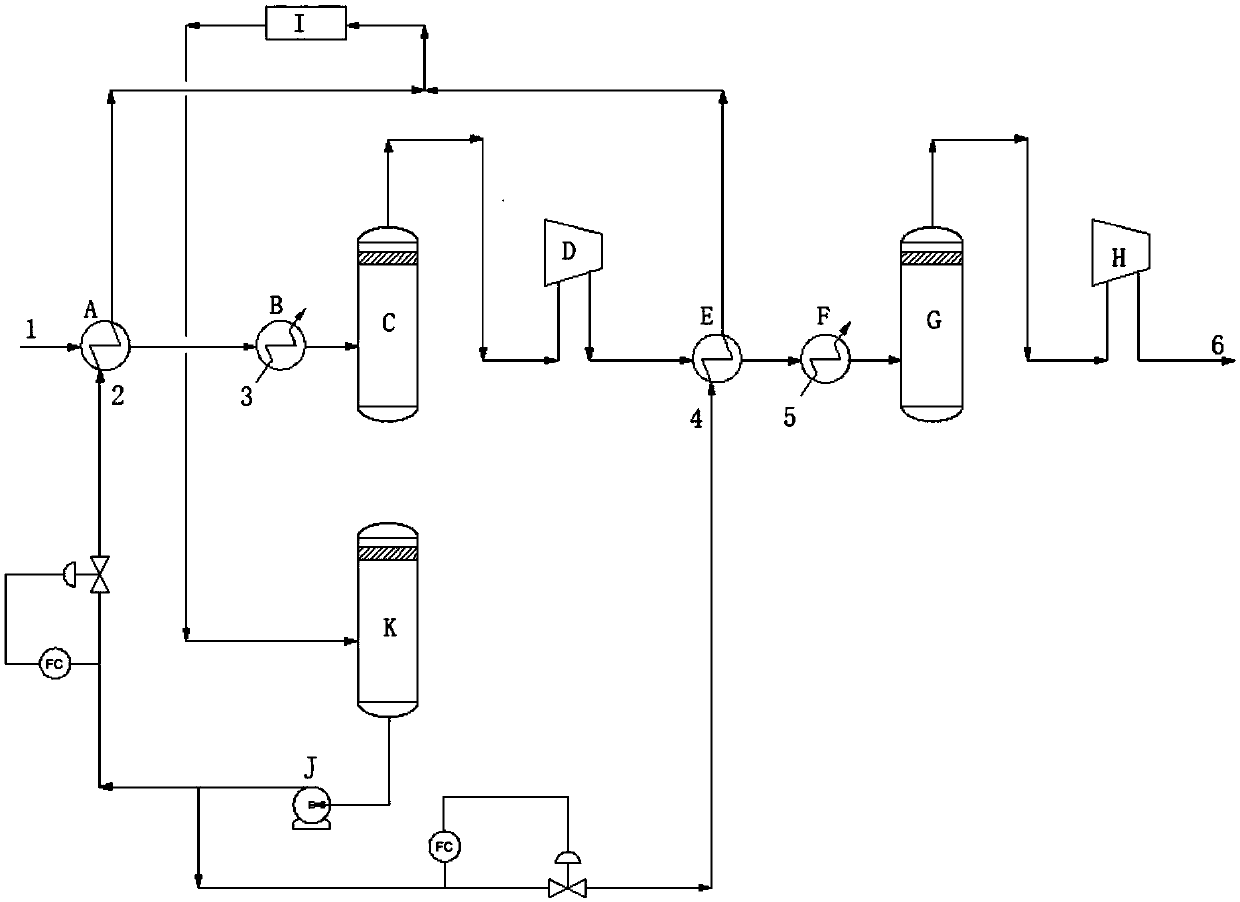

Propane dehydrogenation device waste heat recycling system and method

A propane dehydrogenation and system inlet technology, applied in chemical instruments and methods, indirect heat exchangers, hydrocarbons, etc., can solve the problems of high energy consumption and material consumption of propane, reduce consumption, save low-temperature heat sources, and have obvious advantages Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0047] The temperature of the reactor effluent of the propane dehydrogenation unit is 140°C, and the reactor effluent is sent to such as figure 1 The waste heat shown in the propane dehydrogenation unit is reused in the system. The hot water at 80°C comes from the circulating hot water storage tank (circulating medium storage tank K), is boosted by the hot water circulating pump (circulating medium circulating pump J), and is sent to the first circulating heat exchanger A and the second circulating heat exchanger respectively Device E is used to cool the output of the dehydrogenation reactor and the outlet process gas of the first section of the compressor to the maximum extent. While cooling the process medium, the temperature of the circulating hot water itself is heated to 110 ° C, and then sent to the reboiler I of the separation unit as a Heat source, after heating the process medium, the circulating hot water itself cools down to 80°C and then returns to the hot water st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com