Monitoring method of wafer rapid heat treatment machine

A rapid heat treatment and machine technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, semiconductor/solid-state device testing/measurement, etc., can solve the problem of inability to effectively monitor the temperature fluctuation and drift of rapid heat treatment machines, and the linearity of temperature changes Insufficient temperature sensitivity of resistance and other problems, to achieve the effect of simplifying the production steps and technical requirements, preventing abnormal wafer processing technology, and good market application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

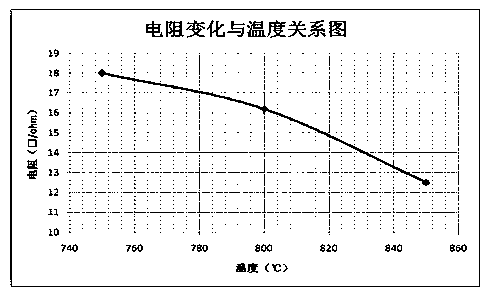

[0044] Embodiment 2, the difference from Embodiment 1 is that in step 3, the ion implantation conditions are, preferably, the implantation conditions are: implantation of impurity P31+, the energy is 65KeV, and the dose is 9.0E13ion / cm 2 , under this injection condition, the resistance change in the incompletely activated state has the best linear relationship with temperature.

[0045] Depend on Figure 4As shown, the temperature changes by 1 degree, and the corresponding resistance value changes by about 1 ohm, which can accurately reflect the temperature fluctuation and drift of the machine;

[0046] Depend on Figure 5 as shown, Figure 5 In order to collect the resistance value fluctuation data for 10 days, it can be seen from the data that the resistance value is stable within + / -3°C, which can accurately reflect the temperature fluctuation and drift, so that the purpose of monitoring the rapid heat treatment machine can be effectively achieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com