Novel dry desulfurization and dust removal device

A technology of dry desulfurization and dedusting equipment, which is applied in the direction of combination equipment, separation methods, chemical instruments and methods, etc., can solve the problems of low desulfurization efficiency, increased cost, increased contact area, etc., and achieve total power consumption and electrical facilities and equipment Low maintenance cost, resource cost saving, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

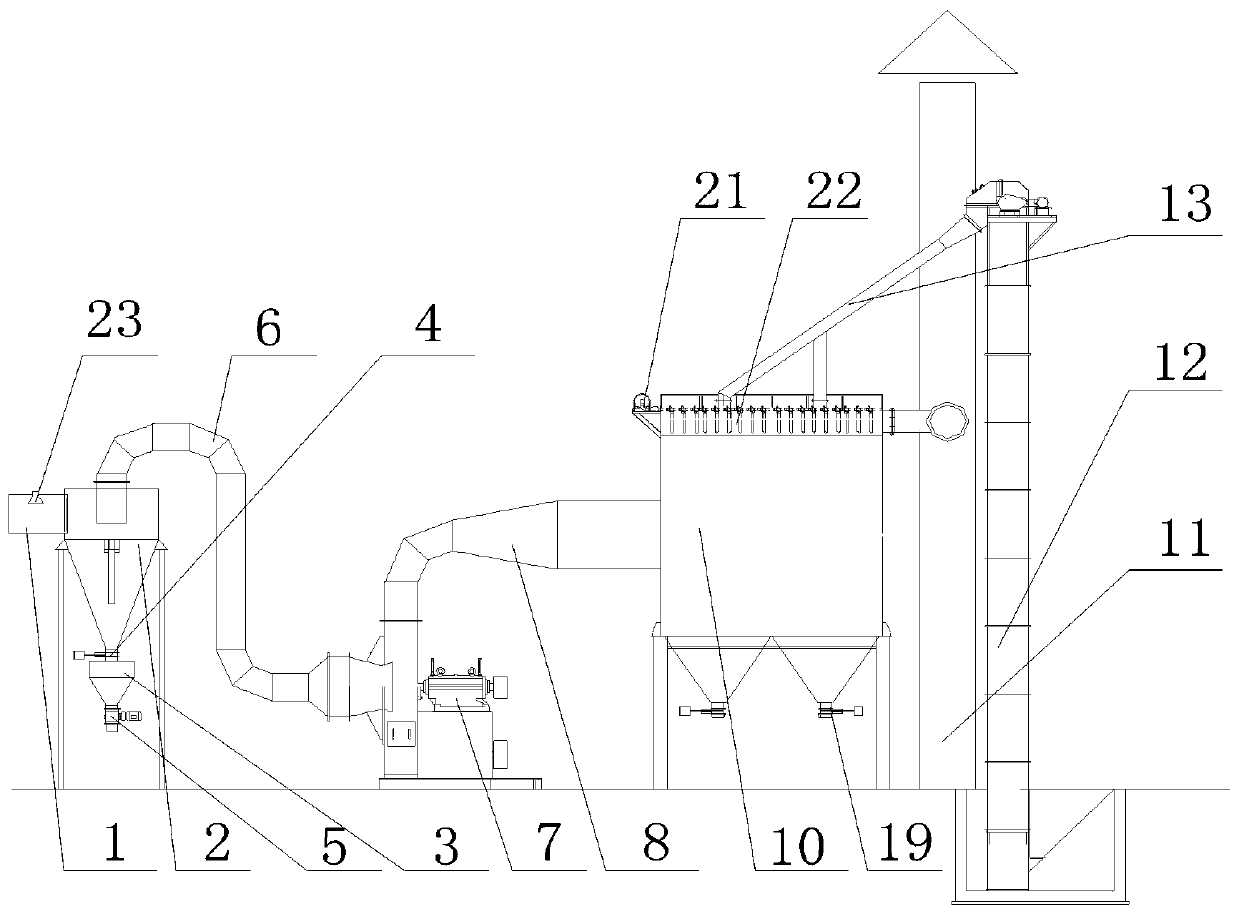

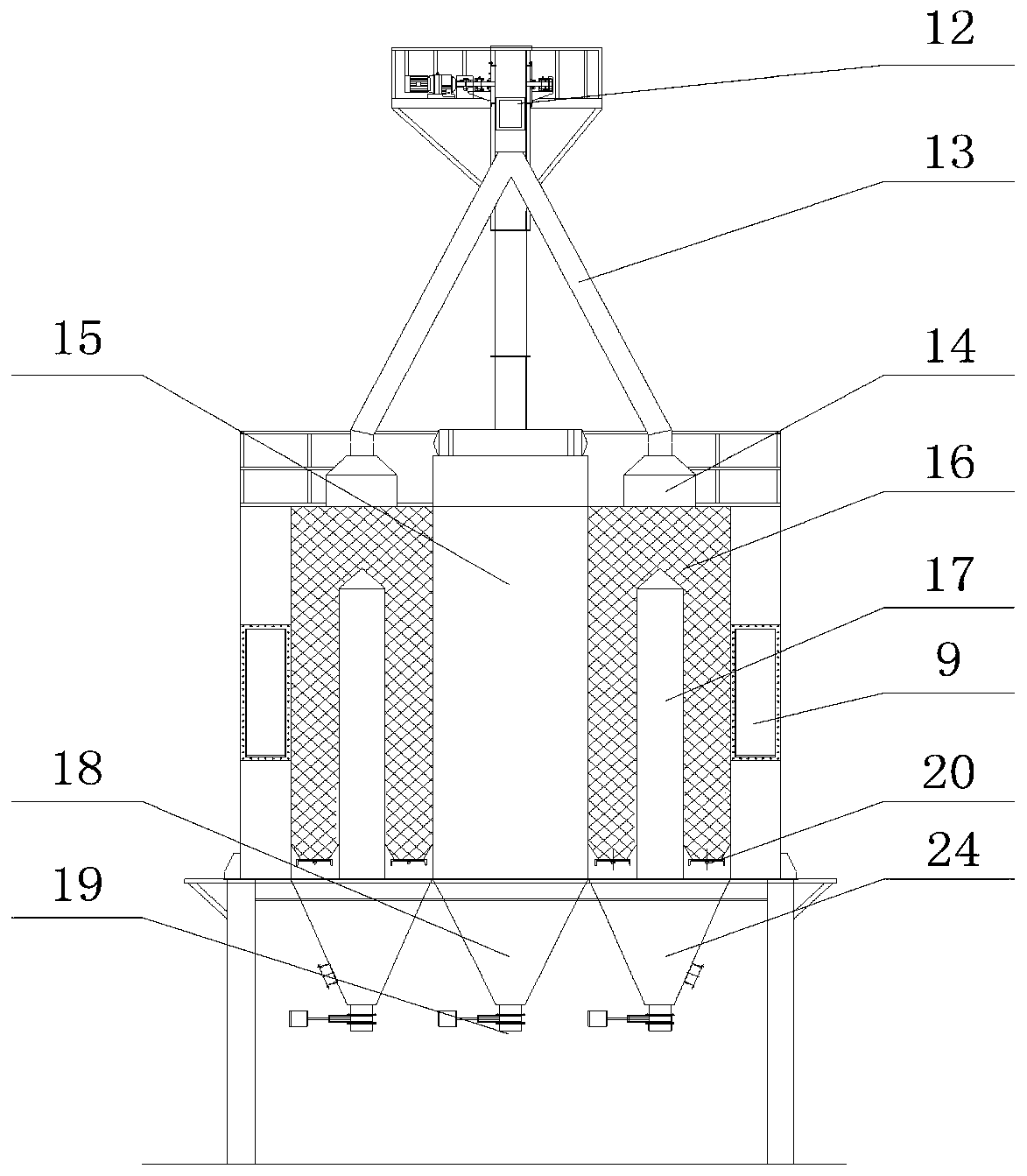

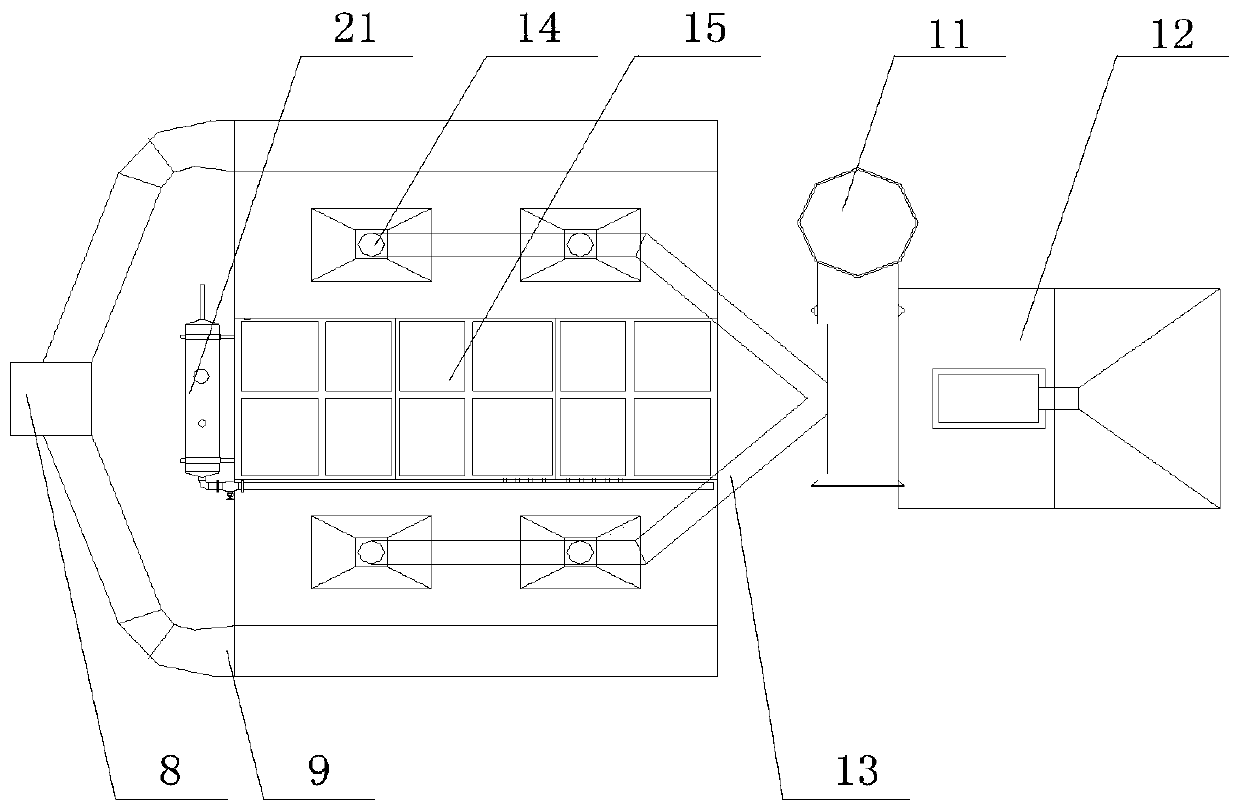

[0028] Such as Figure 1-3As shown, a novel dry desulfurization and dust removal device includes a cyclone dust collector 2, a high-pressure induced draft fan 7, and a bag filter 10. The cyclone dust collector 2 and the high-pressure induced draft fan 7 are connected by a flue 6, and the high-pressure induced draft fan The fan 7 and the bag filter 10 are connected by a high-pressure flue 8, the front end of the cyclone 2 is provided with a flue gas inlet pipe 1, and the bottom of the cyclone 2 is provided with an ash hopper 3, the ash hopper A pneumatic knife valve 4 is provided between the hopper 3 and the cyclone dust collector 2, and a discharge valve 5 is provided at the lower part of the ash hopper 3. The other side of the bag filter 10 is connected to the chimney 11, and the bag filter There are three compartments in the type dust collector 10, the middle compartment is a dust bag room 15, and the two sides are set as active coke bins 16, and the outer side of the active...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com