Method and system for non-contact multi-focus ultrasonic phased array suspension pipetting

An ultrasonic phased array, non-contact technology, applied in the direction of chemical instruments and methods, fluid controllers, laboratory containers, etc., can solve the difficult to meet the requirements of injection, transportation, fusion liquid, huge amount of experimental waste, It is easy to cause mistakes and other problems, and achieves the effect of low design difficulty, good operation stability and affordable price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

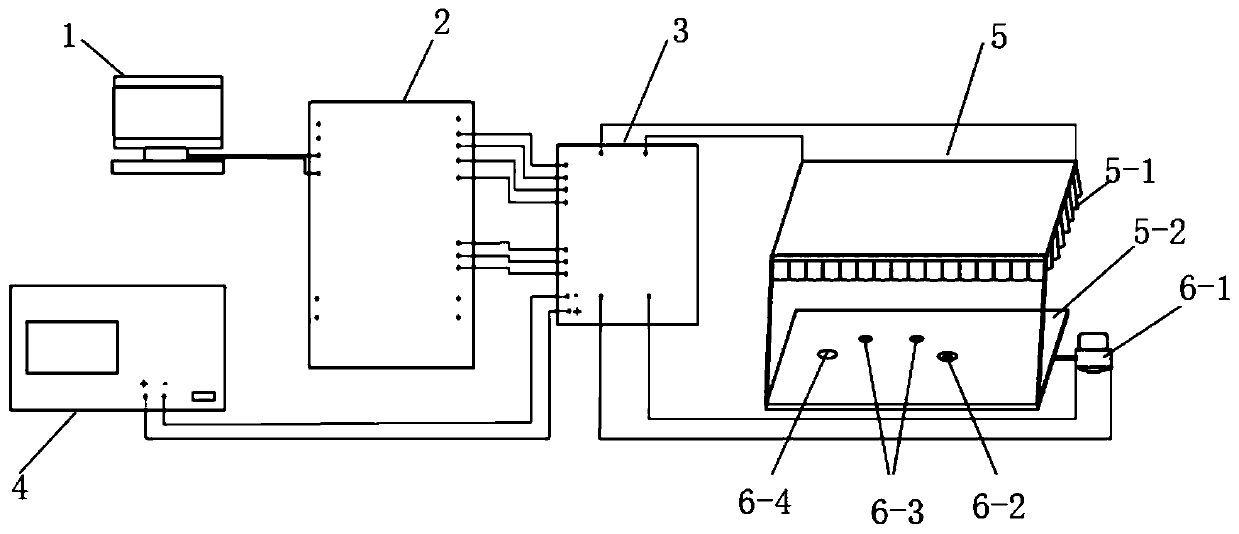

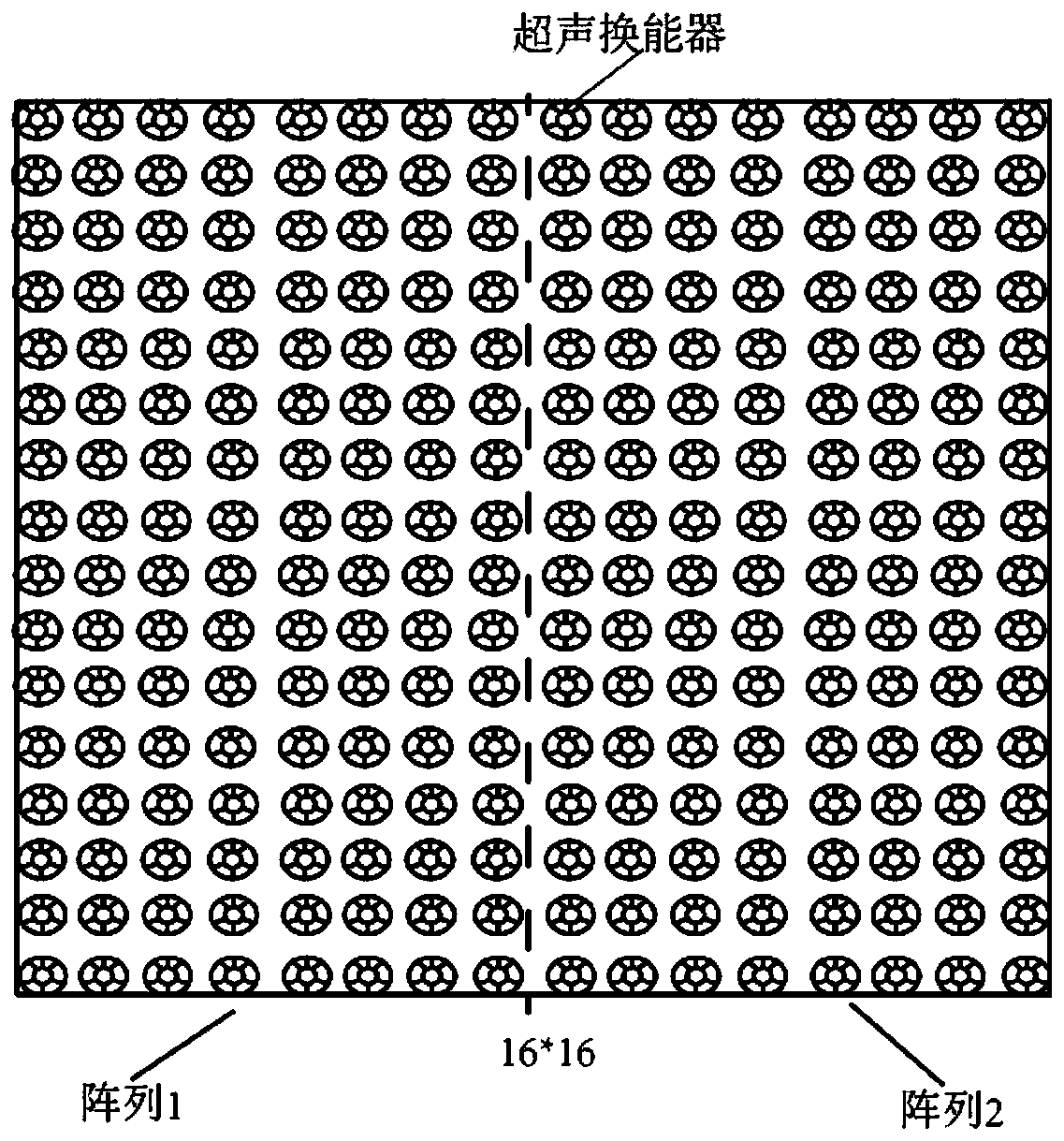

[0039] This embodiment provides a non-contact multi-focus ultrasonic phased array suspension pipetting system, such as figure 1 As shown, it includes a computer module 1, a PWM control module 2, an adjustable regulated power supply module 4, a drive module 3, an ultrasonic array module 5, and a droplet generation module;

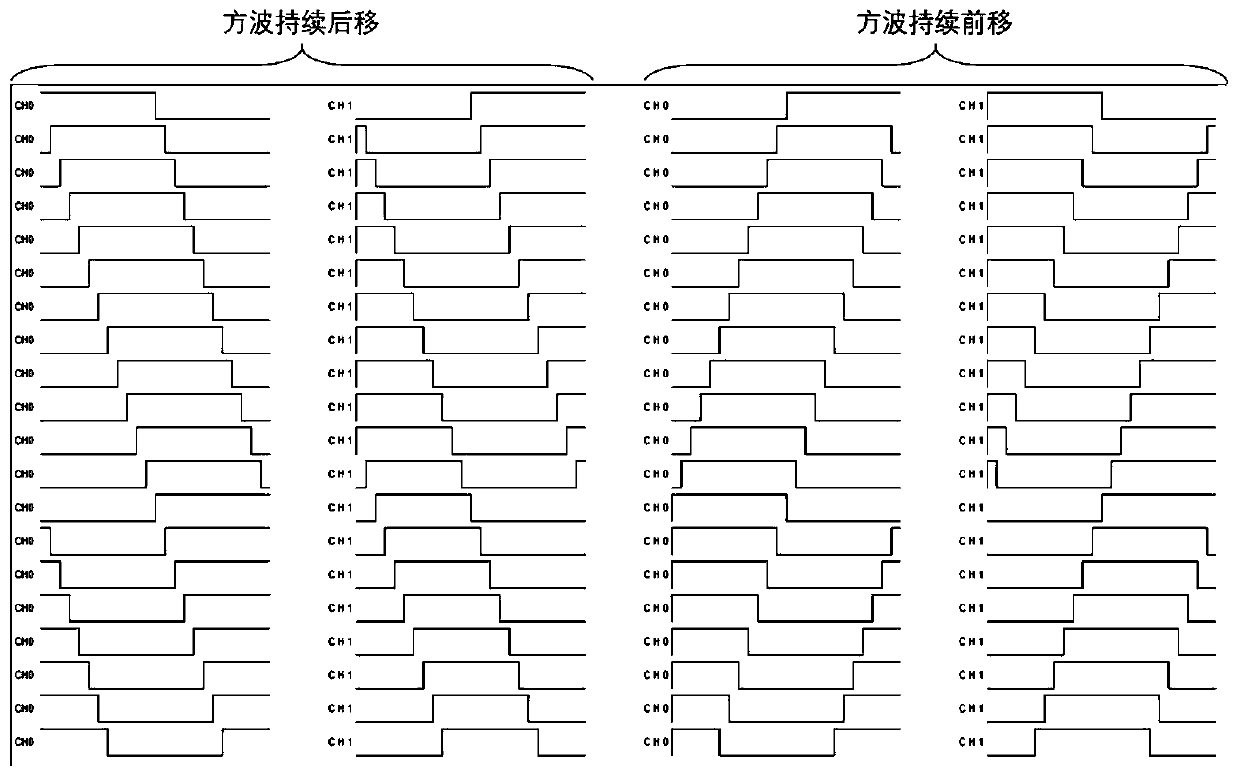

[0040] The computer module 1 sends the received instruction to the PWM control module 2, and the PWM control module 2 calculates the PWM wave frequency and the PWM wave duty ratio corresponding to the instruction; according to the calculation, the PWM wave frequency and the PWM wave duty ratio control the drive module 3 logic input channels; the adjustable regulated power supply module 4 provides amplified power for the drive module 3, so that the output port of the drive module 3 generates a PWM wave with the same voltage amplitude as the adjustable regulated power supply module 4, and the drive module 3 The PWM wave generated by the output port of the inpu...

Embodiment 2

[0078] This embodiment provides a non-contact multi-focus ultrasonic phased array suspension pipetting method, including steps:

[0079] S1. The computer module sends the received instruction to the PWM control module;

[0080] S2. The PWM control module calculates the PWM wave frequency and the PWM wave duty cycle corresponding to the instruction;

[0081] S3. Obtaining the PWM wave frequency and the PWM wave duty ratio according to the calculation to control the logic input channel of the drive module;

[0082] S4. The adjustable regulated power supply module provides amplified power for the drive module, so that the output port of the drive module generates a PWM wave with the same voltage amplitude as the adjustable regulated power supply module, and the output port of the drive module The generated PWM wave is input into the ultrasonic array module or droplet generation module;

[0083] S5. After receiving the PWM wave, the ultrasonic array module generates vibration and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com