Neodymium iron boron magnet processing device

A processing device, neodymium-iron-boron technology, applied in metal processing equipment, manufacturing tools, machine tools designed for grinding the rotating surface of workpieces, etc., can solve problems such as unsatisfactory needs, inconvenient maintenance in the later stage, and reduced production efficiency, etc., to achieve reduction Manual intermediate transfer operation, convenient processing and counting, and the effect of reducing manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

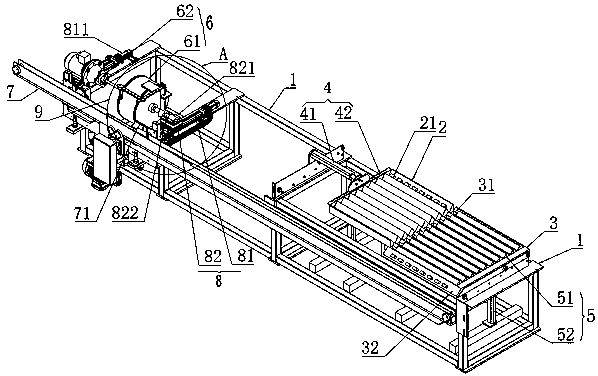

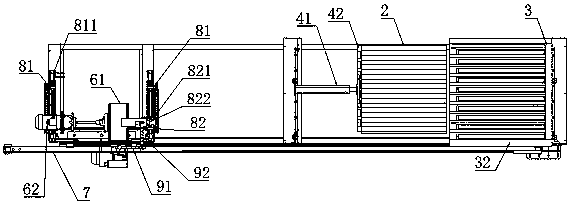

[0033] see Figure 1-7As shown, a processing device for NdFeB magnets of the present invention includes: a first material storage plate 2, a second material storage plate 3, a first material transfer mechanism 4, and a second material transfer mechanism arranged on the tooling frame 1. Mechanism 5, grinding device 6 and conveying line 7 arranged between the second transfer mechanism 5 and the grinding device 6;

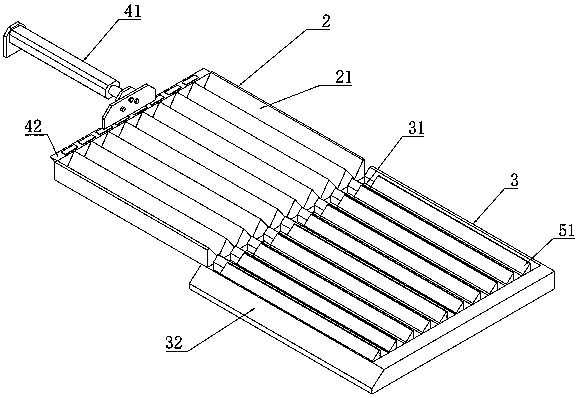

[0034] A number of first accommodation spaces 21 for accommodating materials are horizontally provided on the first material storage plate 2, and a plurality of first accommodation spaces 21 opposite to one end of the second material storage plate 3 are horizontally provided. The second accommodating space 31, and the front end of the second material storage plate 3 is provided with a material guide part 32 for guiding material;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com