Preparation method of 2-amino-5-chlorobenzotrifluoride

A technology of chlorotrifluorotoluene and a manufacturing method, which is applied to the preparation of amino compounds, the preparation of nitro compounds, chemical instruments and methods, etc., can solve the problems of time-consuming, low production efficiency of the manufacturing process, environmental pollution, etc., and achieves high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

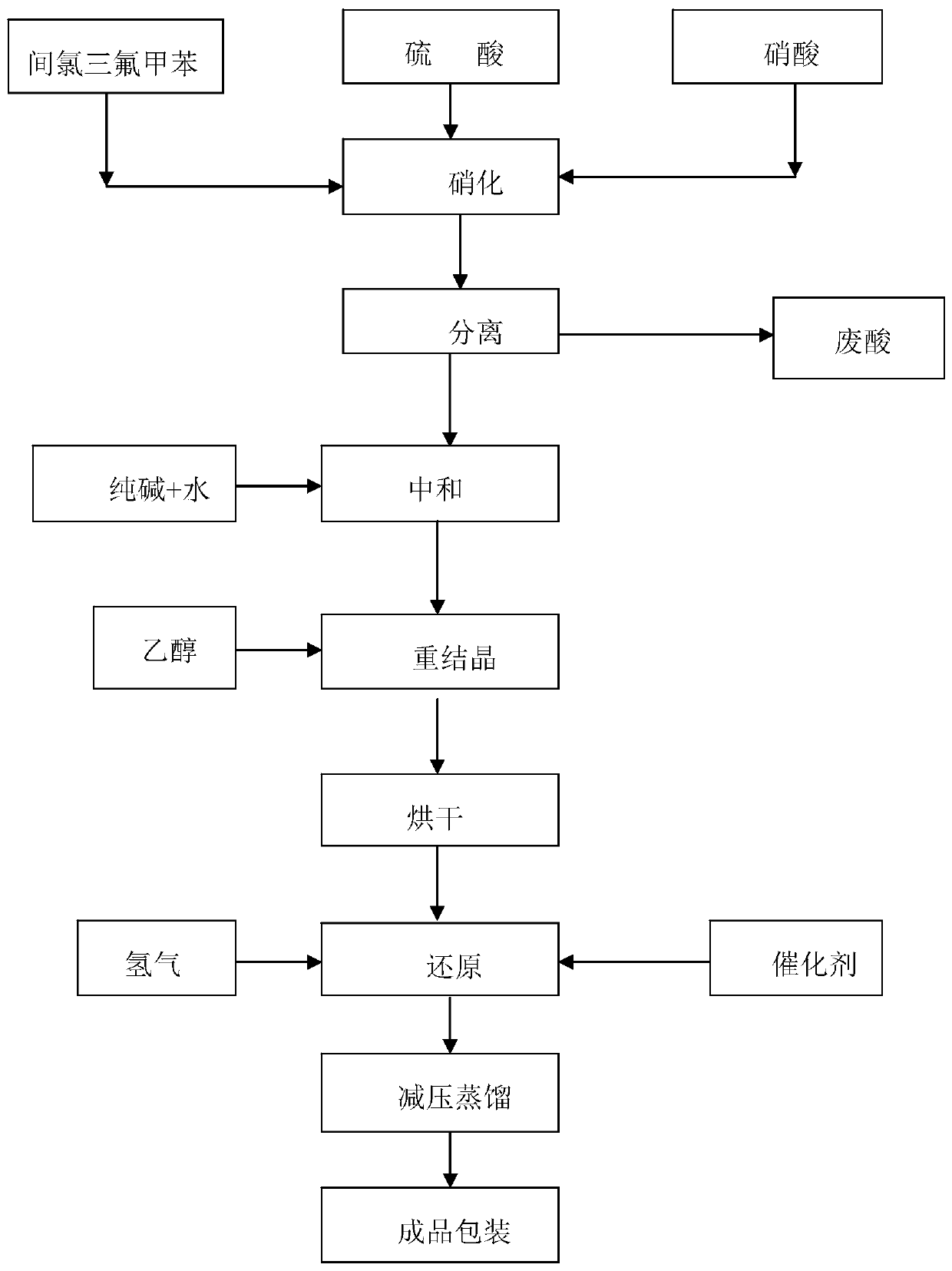

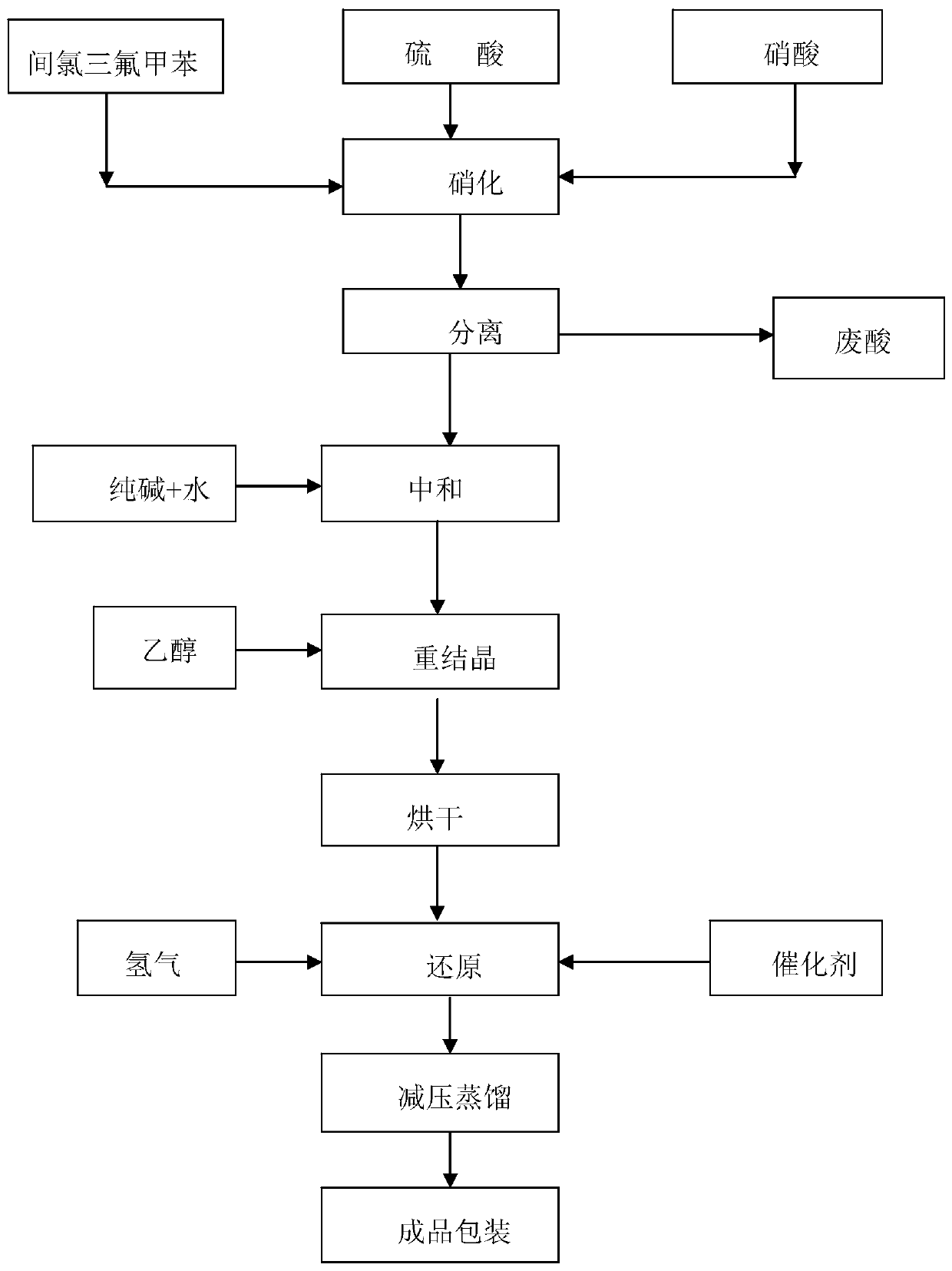

[0024] Such as figure 1 Shown, a kind of manufacture method of 2-amino-5-chlorobenzotrifluoride comprises the following steps:

[0025] In the first step, m-chlorobenzotrifluoride, sulfuric acid and nitric acid are mixed together for nitration reaction; the molar ratio of m-chlorobenzotrifluoride, sulfuric acid and nitric acid is 2:2:5; the reaction temperature is 110°C, and the reaction pressure is 2Mpa ;

[0026] In the second step, the mixture after the nitration in the first step is separated, the reaction mixture is collected, and the waste acid is removed at the same time;

[0027] In the third step, adding soda ash and water to the reaction mixture collected in the second step for neutralization;

[0028] In the fourth step, the neutralized mixture in the third step is added to ethanol for recrystallization;

[0029] The fifth step is to dry the recrystallized mixture in the fourth step; the drying temperature is: 50°C;

[0030] In the sixth step, hydrogen and catal...

Embodiment 2

[0037] A kind of manufacture method of 2-amino-5-chlorobenzotrifluoride, comprises the following steps:

[0038] In the first step, m-chlorobenzotrifluoride, sulfuric acid and nitric acid are mixed together for nitration reaction; the molar ratio of m-chlorobenzotrifluoride, sulfuric acid and nitric acid is 3:4:7; the reaction temperature is 150°C, and the reaction pressure is 0.5 MPa;

[0039] In the second step, the mixture after the nitration in the first step is separated, the reaction mixture is collected, and the waste acid is removed at the same time;

[0040] In the third step, adding soda ash and water to the reaction mixture collected in the second step for neutralization;

[0041] In the fourth step, the neutralized mixture in the third step is added to ethanol for recrystallization;

[0042] The fifth step is to dry the recrystallized mixture in the fourth step; the drying temperature is: 70°C;

[0043] In the sixth step, hydrogen and catalyst are added to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com