Special organic silicon explosion-proof protective coating applied to glass material, and preparation method and use method thereof

An anti-explosion protection and silicone technology, applied in the direction of coating, etc., can solve the problems of not being able to guarantee debris splashing, serious environmental pollution problems, and restricting the use of ink, so as to prevent debris splashing, reduce mechanical equipment requirements, and save ink.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

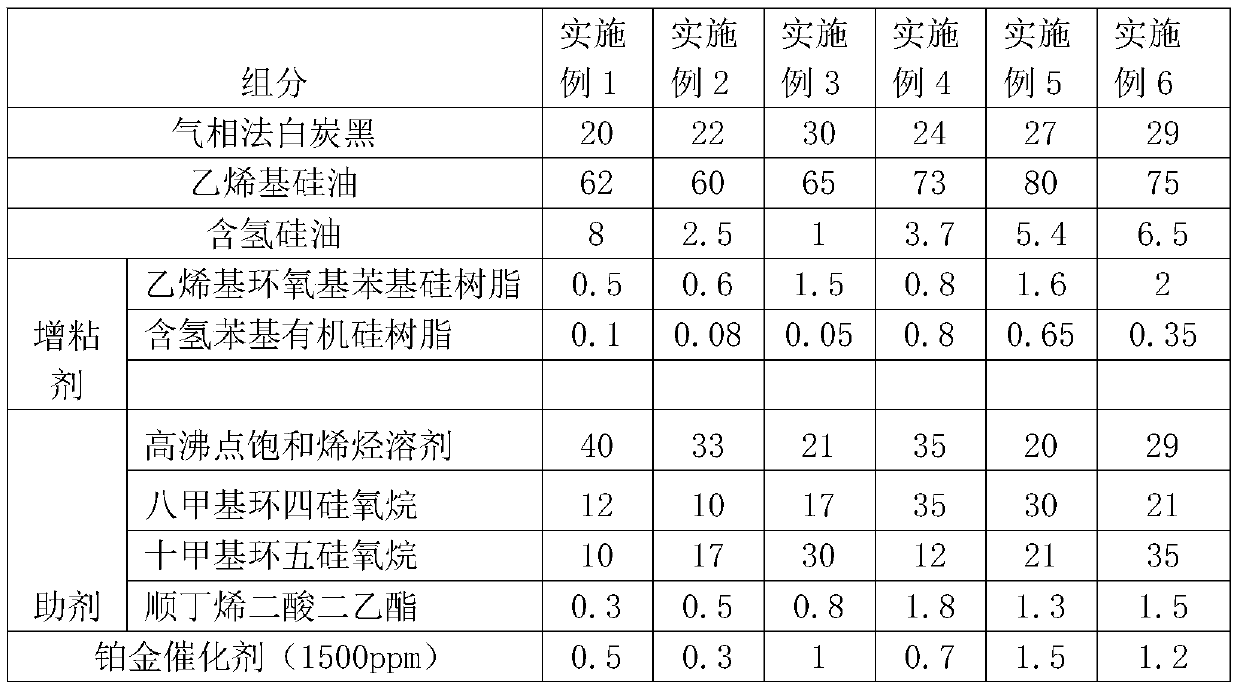

[0020] A special organosilicon explosion-proof protective coating on a glass material of the present application is further described in conjunction with Examples 1-6:

[0021] A preparation method of a special organic silicon explosion-proof protective coating on a glass material, comprising the following steps: adding fumed white carbon black, vinyl silicone oil (terminated vinyl silicone oil or polyvinyl silicone oil) and hydrogen-containing silicone oil by weight in a mixer, Mix at medium speed for 15-30 minutes, then add tackifier and additives and mix at high speed for 10-15 minutes, finally add platinum catalyst and mix at medium speed for 15-25 minutes to obtain special silicone explosion-proof protective coating.

[0022] Table 1: The weight and number ratio of each component in the preparation method of embodiment 1-6

[0023]

[0024] The coating obtained by the preparation method of the above-mentioned Examples 1-6 is dip-coated on the surface of the clean glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com