Unsized needled absorption core body process and device

An absorption core and acupuncture technology, applied in the field of personal hygiene products, can solve the problems of inability to fix fluff pulp and SAP, low production speed of equipment, and impact on the health of users, so as to reduce skin irritation and the release of toxic and harmful substances , Contribute to the protection of the ecological environment and reduce the effect of the natural decomposition cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

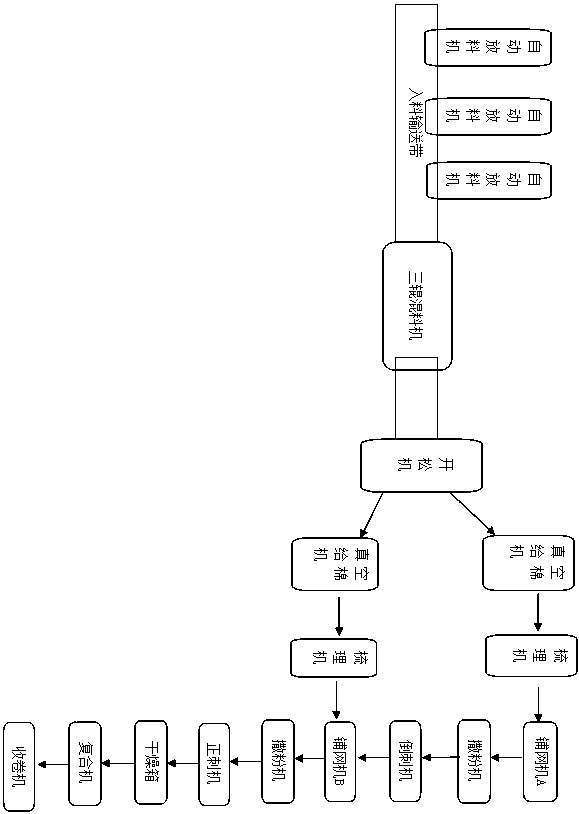

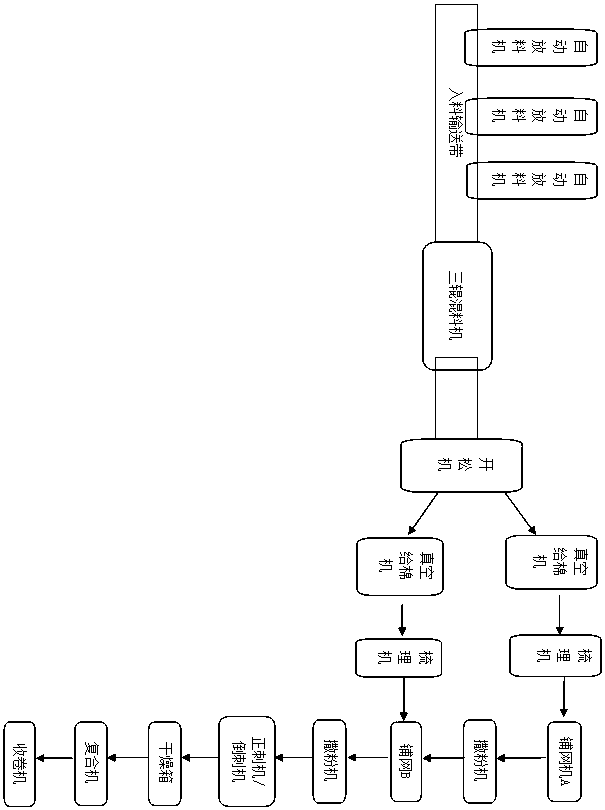

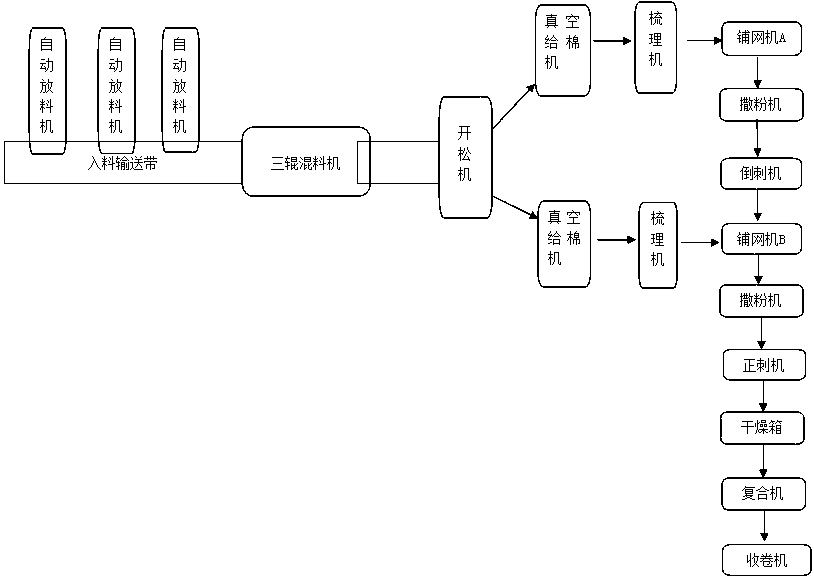

[0052] A method for needle-punching an absorbent core without glue, comprising the following steps:

[0053] 1) Prepare superabsorbent resin particles, non-woven fabrics, and cotton fiber bags;

[0054] 2) For the cotton fiber mixture, use an opener to open the mixture and send it to the vacuum cotton feeder;

[0055] 3) Send the cotton fiber processed by the vacuum feeding machine into the carding machine;

[0056] 4) The cotton fiber processed by the carding machine enters the web-laying machine, and the cotton fiber web formed by the web-laying machine is laid on the non-woven fabric;

[0057] 5) Sprinkle superabsorbent resin particles on the cotton fiber net with a powder spreader;

[0058] 6) Pre-needle the semi-finished product in step 5) with a barb machine;

[0059] 7) Continue laying a layer of cotton fiber net on the semi-finished product needled through step 6);

[0060]8) Use a powder spreader to sprinkle super absorbent resin particles on the cotton fiber net;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com