Plastic runway with good anti-skid effect and construction process

A plastic runway and anti-skid layer technology, applied in roads, roads, buildings, etc., can solve the problems of wear, aging of the plastic runway surface, poor anti-skid performance of the plastic runway, etc., and achieve the effect of convenient drainage and enhanced water absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

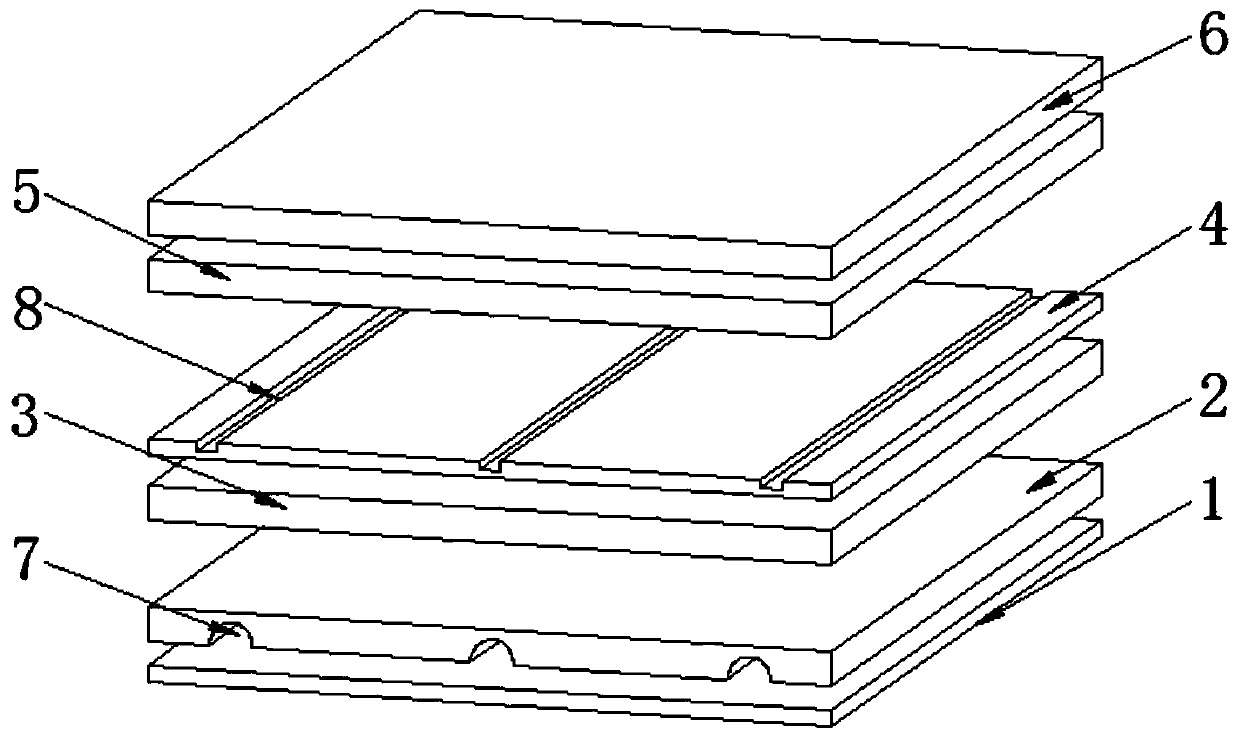

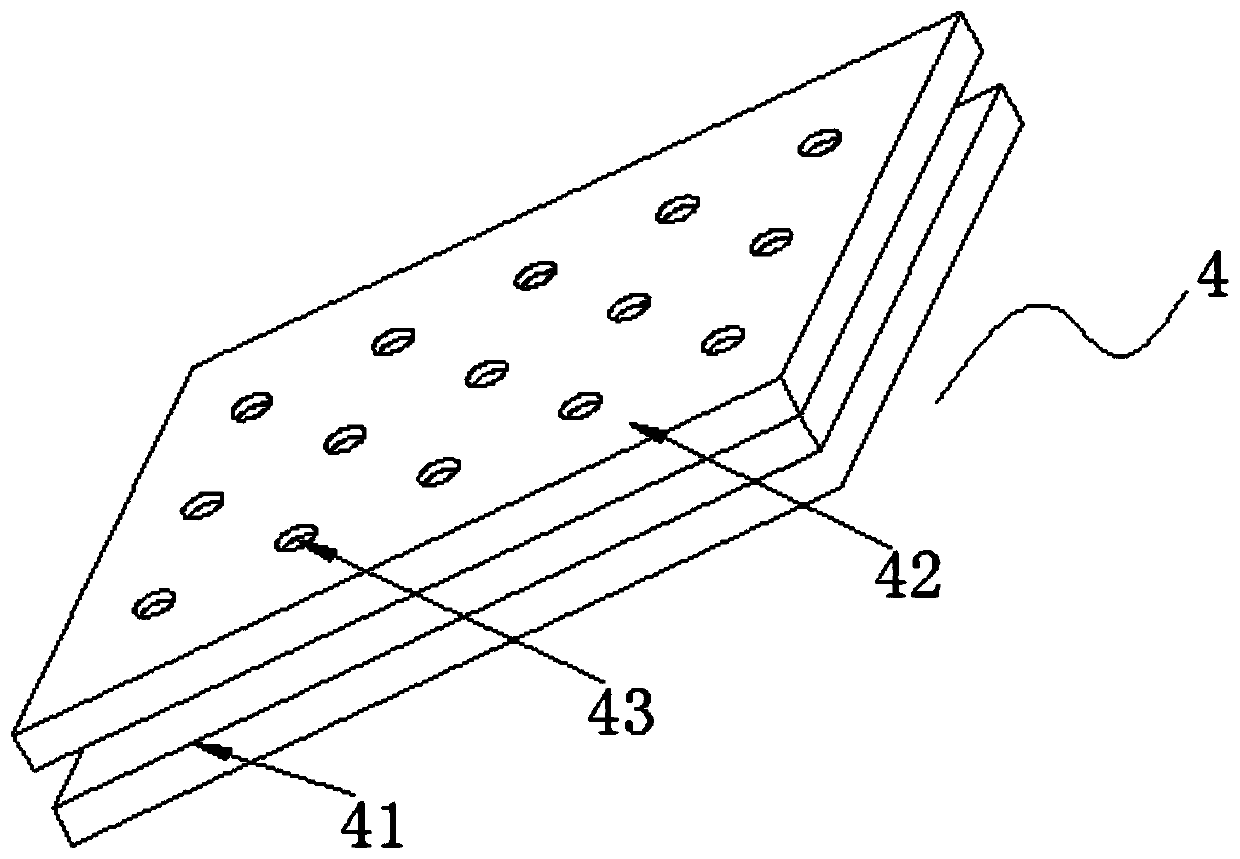

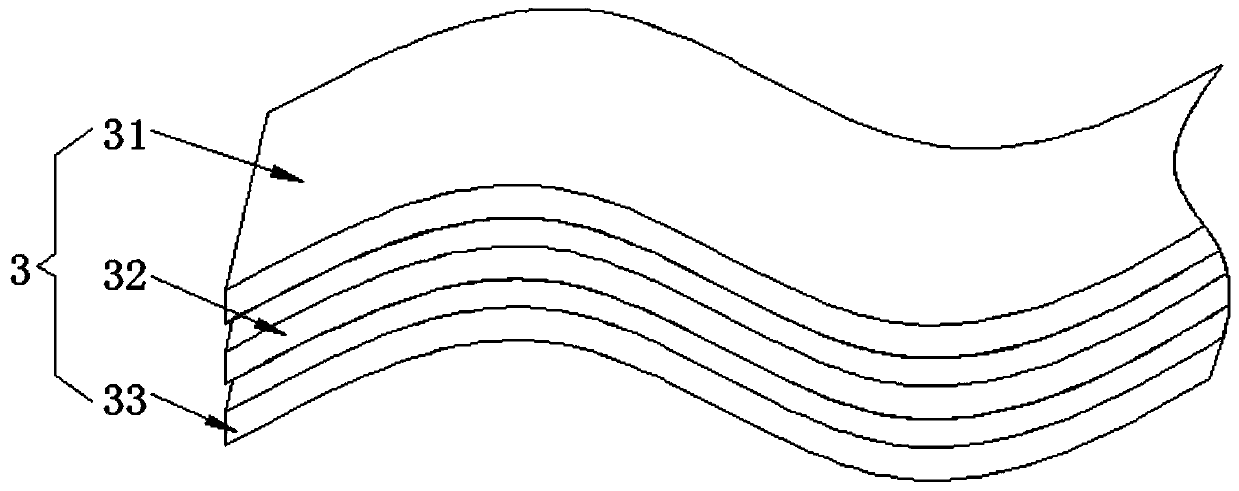

[0031] Including crushed stone layer 1, concrete layer 2, permeable layer 3, elastic layer 4, polyurethane rubber layer 5 and anti-slip layer 6, elastic layer 4 includes a first rubber layer 41 and a second rubber layer 42, the top of the first rubber layer 41 The bottom of the second rubber layer 42 is fixedly connected by an adhesive, the surfaces of the first rubber layer 41 and the second rubber layer 42 are provided with through holes 43, and the permeable layer 3 includes the first water-absorbing layer 31, the filter layer 32 and the second rubber layer. Two water-absorbing layers 33, the top of the filter layer 32 is fixedly connected with the bottom of the first water-absorbing layer 31, the first water-absorbing layer 31, the filter layer 32 and the second water-absorbing layer 33 are all fixedly connected by adhesive, the second water-absorbing layer The top of 33 is fixedly connected with the bottom of filter layer 32, the top of gravel layer 1 is fixedly connected ...

Embodiment 2

[0038]Including crushed stone layer 1, concrete layer 2, permeable layer 3, elastic layer 4, polyurethane rubber layer 5 and anti-slip layer 6, elastic layer 4 includes a first rubber layer 41 and a second rubber layer 42, the top of the first rubber layer 41 The bottom of the second rubber layer 42 is fixedly connected by an adhesive, the surfaces of the first rubber layer 41 and the second rubber layer 42 are provided with through holes 43, and the permeable layer 3 includes the first water-absorbing layer 31, the filter layer 32 and the second rubber layer. Two water-absorbing layers 33, the top of the filter layer 32 is fixedly connected with the bottom of the first water-absorbing layer 31, the first water-absorbing layer 31, the filter layer 32 and the second water-absorbing layer 33 are all fixedly connected by adhesive, the second water-absorbing layer The top of 33 is fixedly connected with the bottom of filter layer 32, the top of gravel layer 1 is fixedly connected w...

Embodiment 3

[0045] Including crushed stone layer 1, concrete layer 2, permeable layer 3, elastic layer 4, polyurethane rubber layer 5 and anti-slip layer 6, elastic layer 4 includes a first rubber layer 41 and a second rubber layer 42, the top of the first rubber layer 41 The bottom of the second rubber layer 42 is fixedly connected by an adhesive, the surfaces of the first rubber layer 41 and the second rubber layer 42 are provided with through holes 43, and the permeable layer 3 includes the first water-absorbing layer 31, the filter layer 32 and the second rubber layer. Two water-absorbing layers 33, the top of the filter layer 32 is fixedly connected with the bottom of the first water-absorbing layer 31, the first water-absorbing layer 31, the filter layer 32 and the second water-absorbing layer 33 are all fixedly connected by adhesive, the second water-absorbing layer The top of 33 is fixedly connected with the bottom of filter layer 32, the top of gravel layer 1 is fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com