Tunnel kiln radiation heat exchange type waste heat boiler

A technology of radiation heat exchange and waste heat boiler, which is applied to steam boilers, steam boiler accessories, components of steam boilers, etc. It can solve the problems of high cost, long cooling time, and low efficiency of waste heat utilization, so as to prevent corrosion and improve use Effect, Protection Effect of Normal Use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

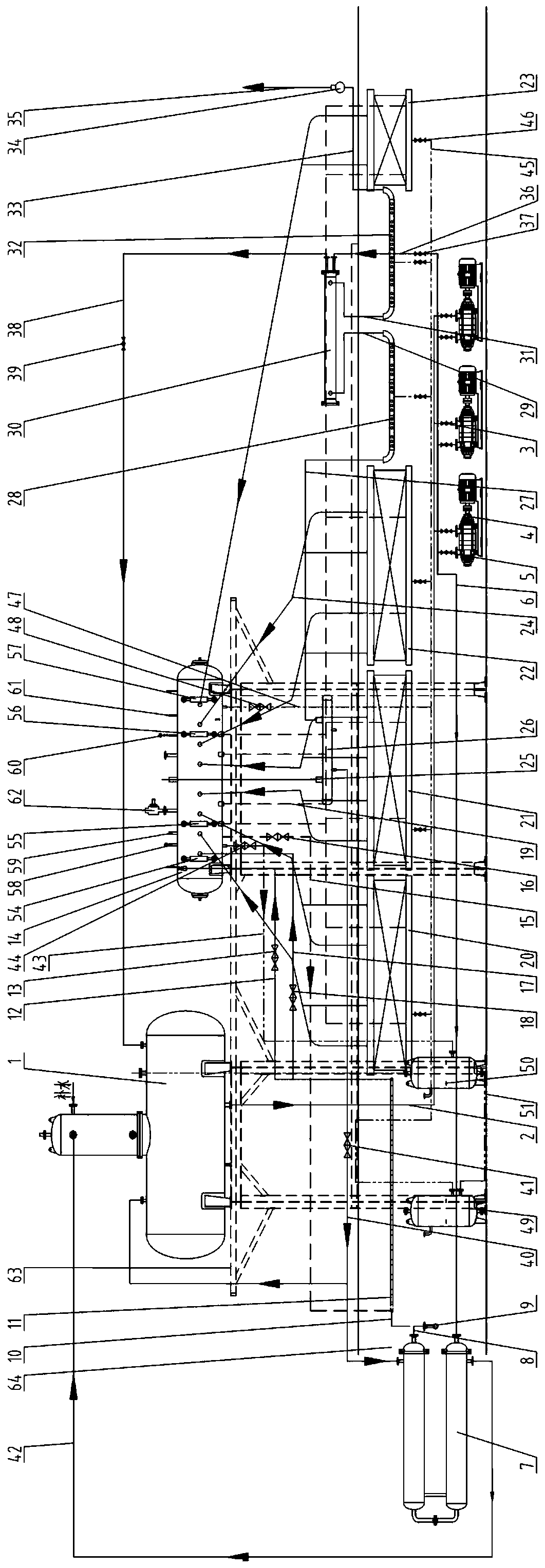

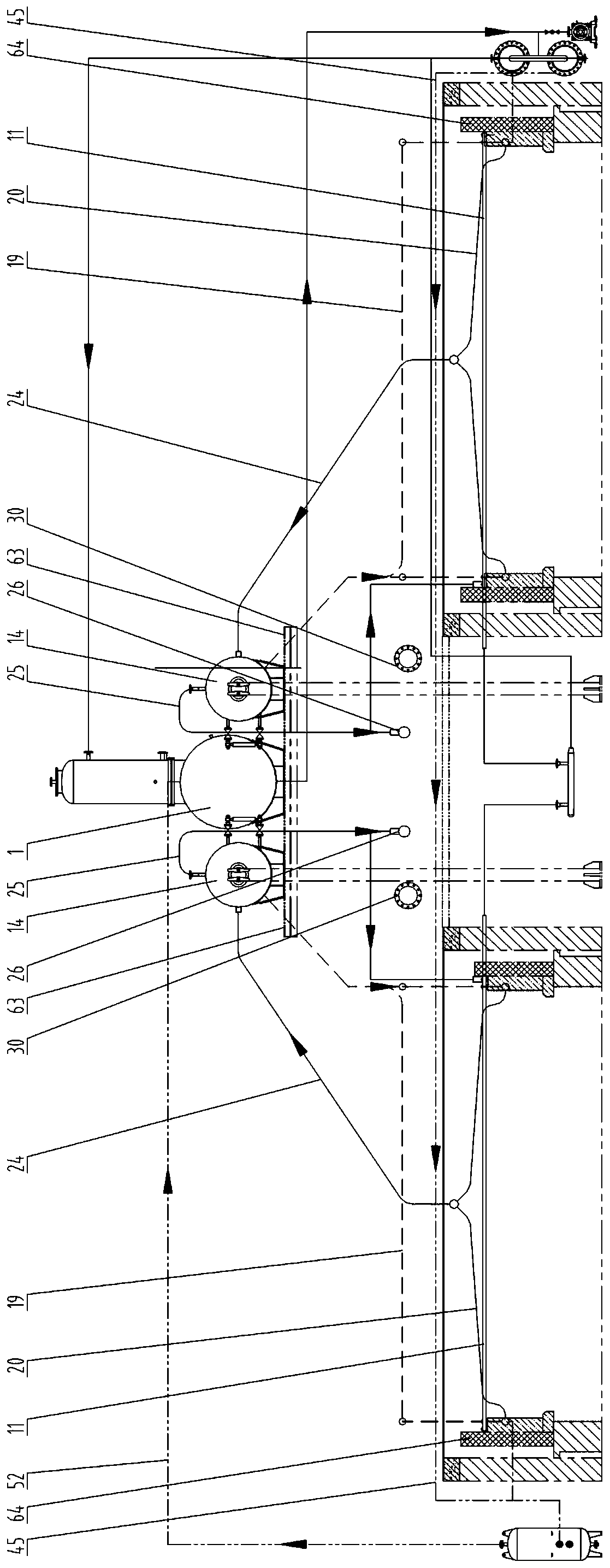

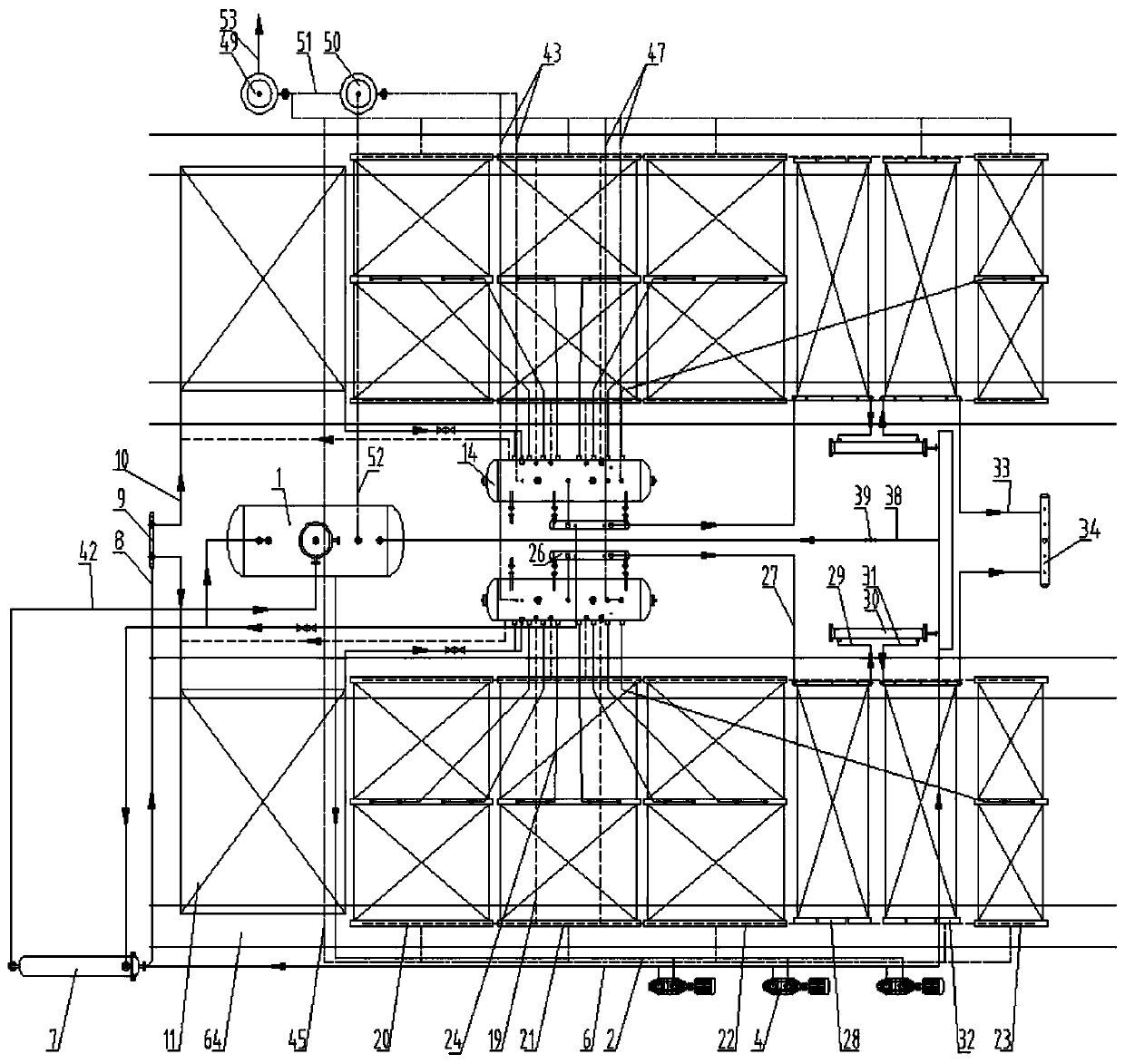

[0027] Such as Figure 1-3 As shown, a tunnel kiln radiation heat exchange waste heat boiler includes a boiler steel structure support platform 63 arranged outside the tunnel kiln 64, a deaerator 1 arranged on the boiler steel structure support platform 63 and connected to a water supply port. , the secondary steam port of the deaerator 1 is connected with a continuous blowdown expanding vessel 50 through a secondary steam pipe 52, and the continuous blowdown expanding vessel 50 is connected with a regular blowdown expanding vessel 49 through a capacity expansion connecting pipe 51, and the regular blowdown expanding vessel 49 is recovered through blowdown The pipe 53 is connected with external equipment, the water outlet of the deaerator 1 is connected to the feedwater pump 4 through the feedwater pump inlet pipe 2, and the feedwater pump 4 is also connected to the economizer inlet header 9, and the economizer inlet header 9 The economizer 11 is connected to the economizer wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com