Integrated packaging structure and packaging method of surface acoustic wave sensor

A technology of surface acoustic wave and packaging structure, which is applied in the direction of transmitting sensing components, instruments, measuring devices, etc. by using electric/magnetic devices, and can solve the problem of unfavorable acoustic surface wave sensor process feasibility, test reliability, and unfavorable acoustic surface. The wave sensor was quickly deployed, installed and tested, and no problems such as instructions or reports were found, so as to facilitate on-site installation and engineering application, reduce size, and improve hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following is a detailed description of the embodiments of the present invention: this embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation methods and specific operation processes. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention.

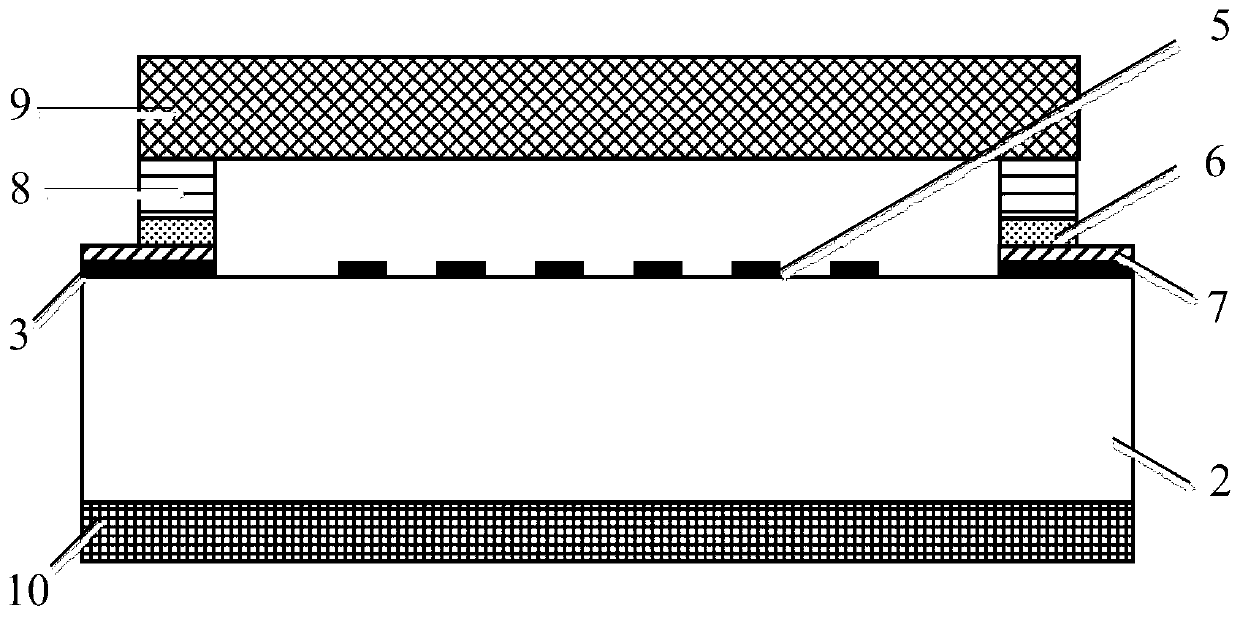

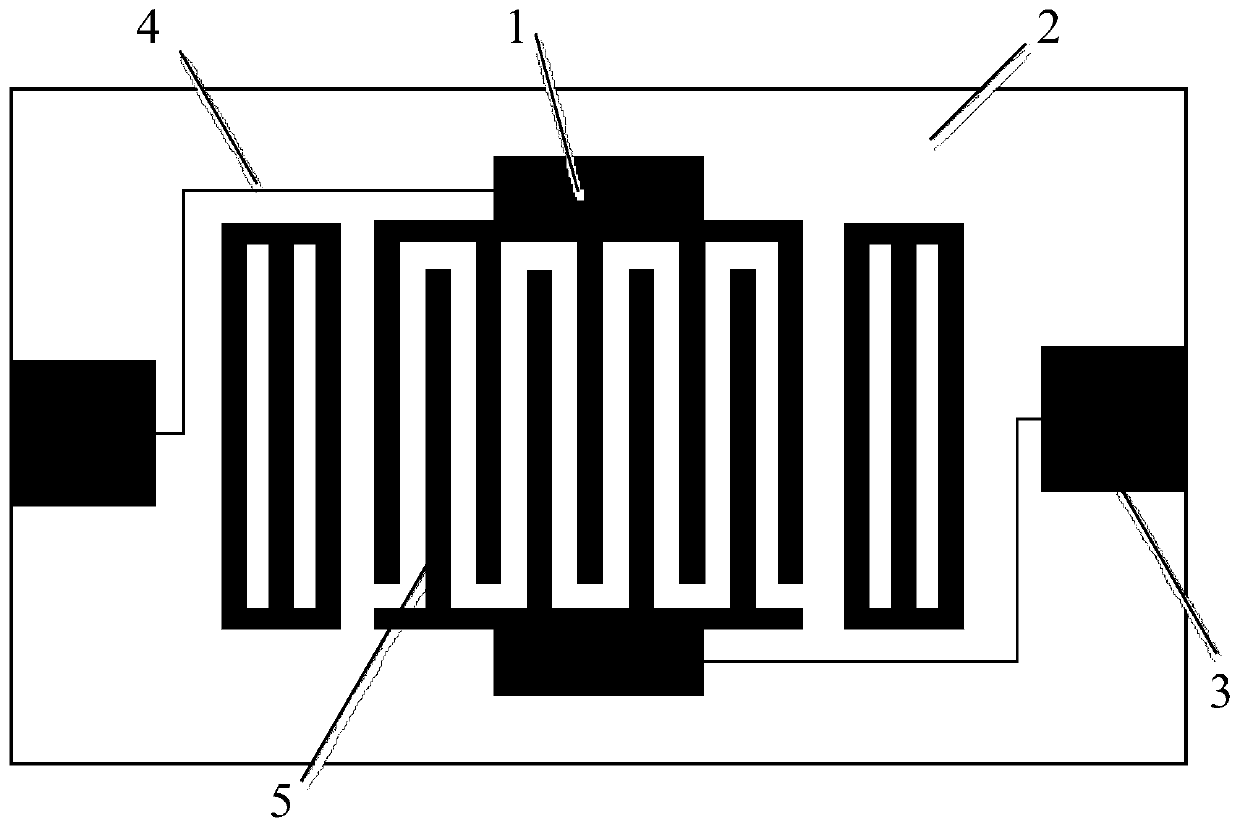

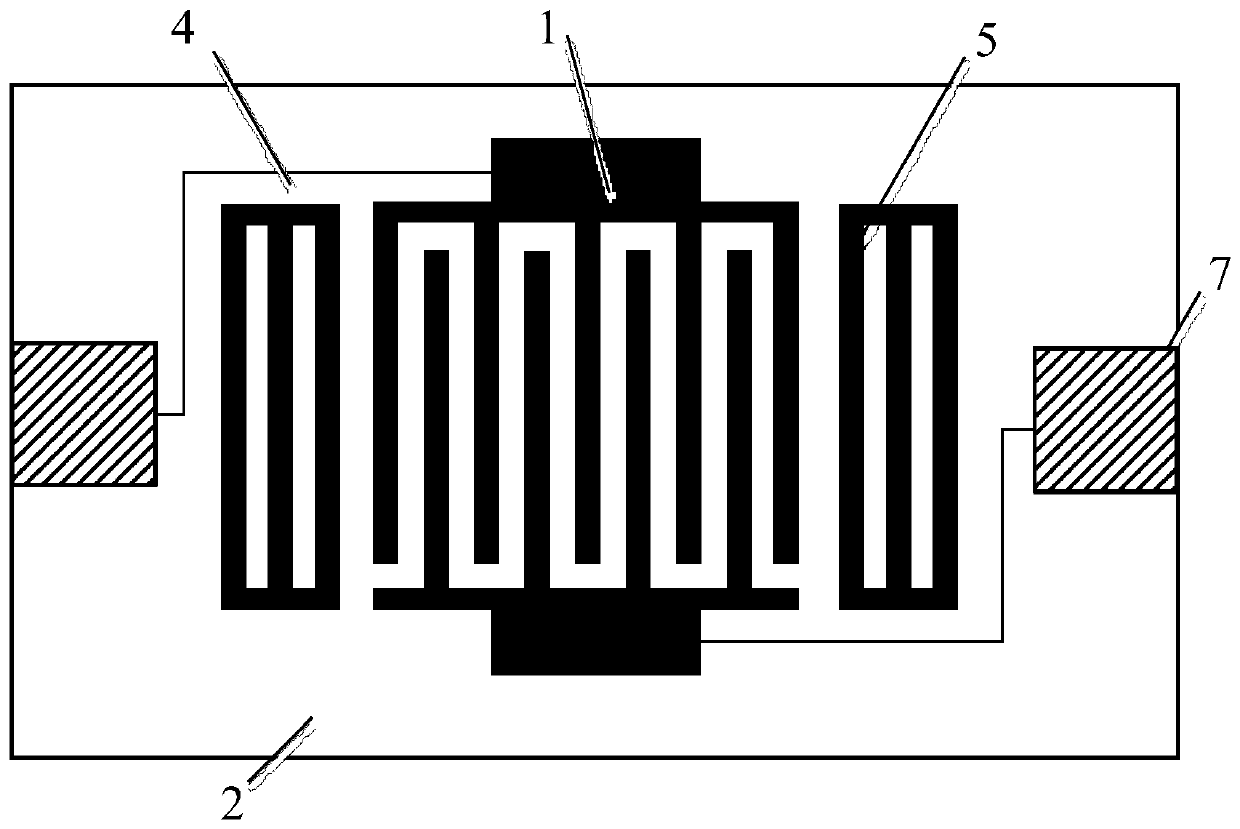

[0043] An embodiment of the present invention provides an integrated packaging structure of a surface acoustic wave sensor, including: a passivation insulating protection layer 6, a pad coating 7, a metal support frame 8, and a high-strength metal cover plate 9; wherein:

[0044] The insulating protection layer 6 is SiO deposited on the upper surface of the sensor substrate 2 2 Insulation layer (it should be noted that this is not limited to SiO 2, as long as the material with stable c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com